-

What happened?

A technician was working on a drillship.

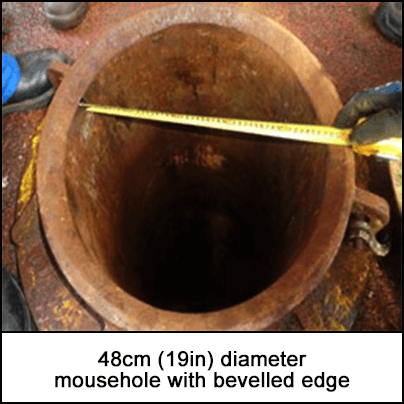

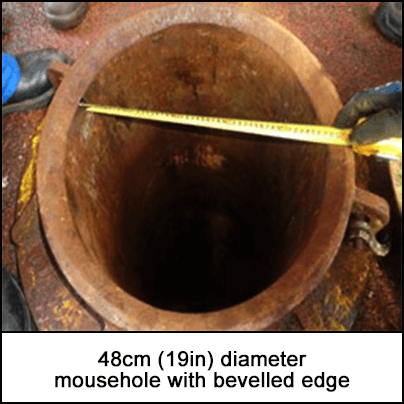

The drillship was fitted with a ‘mousehole’ of 48cm (19in) diameter to accommodate the enhanced landing string assembly (ELSA) and other large tools.

The mousehole had been modified from its original design (top flanges had been bevelled to allow easier entry of pipe and tools).

At the same time, new cover plates had been created for the rotary table. The old cover plates were roughly the same size and colour as the mousehole cover plate and were left on the rig floor.

An old rotary cover plate had been placed over the mousehole.

The technician stepped back onto the cover plate of the mousehole. The ill-fitting cover dislodged, and the technician dropped inside the mousehole.

The technician managed to catch themselves with their forearms and was lifted out by co-workers. If the workers had fell all the way, there was no rescue plan in place.

-

Why did it happen?

Several changes had been made to the equipment (bevel on mousehole and construction of new hole covers) without a management of change that recognised the consequences.

The rotary table cover looked similar to the mousehole cover.

The bevelled edges of the mousehole meant the rotary cover did not fit securely (nor was it designed to).

The hazards of falling into a large diameter mousehole were not recognised. Furthermore, the rig team was not prepared and had no plan in place for rescue.

-

What did they learn?

Follow a management of change process to account for the potential consequences of modifications.

Ensure the risks associated with mouseholes are fully considered and managed.

Ensure there is a rescue plan in place for the event a worker falls into a mousehole.

-

Ask yourself or your crew

How strong are the physical barriers that you have at your worksite? Are they engineered? Do you have procedures in place to prevent incorrect use? Can your hole covers be inadvertently exchanged?

How robust are your management of change procedures? Do they recognize the potential consequences of the change?

How you would rescue an injured person trapped 38m below deck in a large diameter mousehole?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A technician was working on a drillship.

The drillship was fitted with a ‘mousehole’ of 48cm (19in) diameter to accommodate the enhanced landing string assembly (ELSA) and other large tools.

The mousehole had been modified from its original design (top flanges had been bevelled to allow easier entry of pipe and tools).

At the same time, new cover plates had been created for the rotary table. The old cover plates were roughly the same size and colour as the mousehole cover plate and were left on the rig floor.

An old rotary cover plate had been placed over the mousehole.

The technician stepped back onto the cover plate of the mousehole. The ill-fitting cover dislodged, and the technician dropped inside the mousehole.

The technician managed to catch themselves with their forearms and was lifted out by co-workers. If the workers had fell all the way, there was no rescue plan in place.

Why did it happen?

Several changes had been made to the equipment (bevel on mousehole and construction of new hole covers) without a management of change that recognised the consequences.

The rotary table cover looked similar to the mousehole cover.

The bevelled edges of the mousehole meant the rotary cover did not fit securely (nor was it designed to).

The hazards of falling into a large diameter mousehole were not recognised. Furthermore, the rig team was not prepared and had no plan in place for rescue.

What did they learn?

Follow a management of change process to account for the potential consequences of modifications.

Ensure the risks associated with mouseholes are fully considered and managed.

Ensure there is a rescue plan in place for the event a worker falls into a mousehole.

Ask yourself or your crew

How strong are the physical barriers that you have at your worksite? Are they engineered? Do you have procedures in place to prevent incorrect use? Can your hole covers be inadvertently exchanged?

How robust are your management of change procedures? Do they recognize the potential consequences of the change?

How you would rescue an injured person trapped 38m below deck in a large diameter mousehole?

A technician was working on a drillship when they stepped back onto the cover of a mousehole. The cover slipped and the technician fell into the mousehole