-

What happened?

An intermittent alarm sounded for the bilge access tunnel in a tension leg platform (TLP).

The alarm was investigated and found to be seawater flooding – 2ft below level 1 mezzanine.

The workers tried to isolate the valve, but it did not close, so a bilge pump was started and lined up to access the tunnel bilge.

The water was still rising and approaching the fire water pump room level (20m/65ft from the bottom). A support vessel was called to the location for assistance.

Non-essential personnel were evacuated.

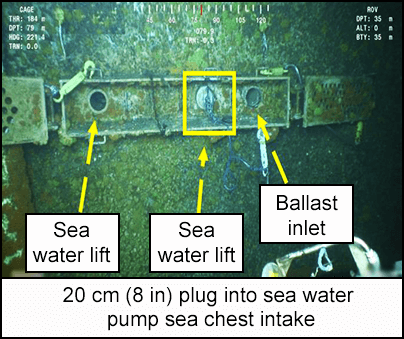

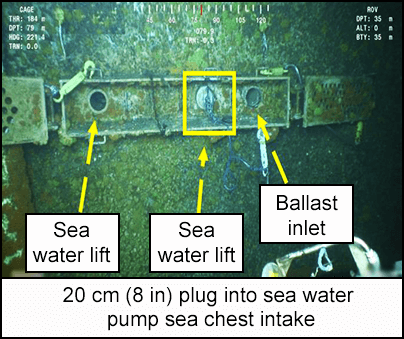

The support vessel used a remote operated vehicle (ROV) to install a 20cm (8in) plug into the sea chest intake.

The inflow of water stopped and 3 hours later everyone was allowed back on board.

19 hours later the water had reduced enough to enter the column and close the manual sea chest valve on the bilge pump.

-

Why did it happen?

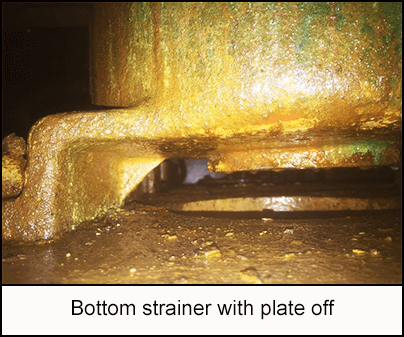

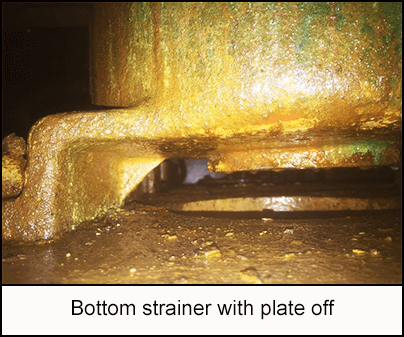

The bottom flange of a sea water lift (SWL) strainer was separated due to corroded bolts.

The strainer has been leaking slowly for months. Workers pumped the bilge regularly, which became a ‘normal’ process.

The work order to repair the strainer was considered low priority, so had not been actioned.

The alarm was stopped several times without investigation, and not investigated until a secondary warning alarm was raised.

The valve was classed as ‘non-critical’ and had no regular inspection regime.

No regular maintenance scheme in place to look at strainers, seals and the UV on the piping systems for sea water.

-

What did they learn?

Make sure that all alarms are investigated – a regular alarm is not ‘normal’.

Implement inspections and maintenance regimes for marine systems equipment such as strainers bolting, seals replacement (bottom strainer with plate off), and piping system for sea water.

Ensure that all work orders are looked at, even if they do not seem to be safety critical.

-

Ask yourself or your crew

What is the worst that could have happened?

Are you operating pieces of equipment using workarounds that have become ‘normal’?

Is your maintenance program adequate (frequency, type of checks)? Does it cover all necessary equipment and areas (such as marine systems)?

Are all alarms identified and checked to confirm that action is taken as necessary?

What measures do we have in place to prevent this from happening here? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An intermittent alarm sounded for the bilge access tunnel in a tension leg platform (TLP).

The alarm was investigated and found to be seawater flooding – 2ft below level 1 mezzanine.

The workers tried to isolate the valve, but it did not close, so a bilge pump was started and lined up to access the tunnel bilge.

The water was still rising and approaching the fire water pump room level (20m/65ft from the bottom). A support vessel was called to the location for assistance.

Non-essential personnel were evacuated.

The support vessel used a remote operated vehicle (ROV) to install a 20cm (8in) plug into the sea chest intake.

The inflow of water stopped and 3 hours later everyone was allowed back on board.

19 hours later the water had reduced enough to enter the column and close the manual sea chest valve on the bilge pump.

Why did it happen?

The bottom flange of a sea water lift (SWL) strainer was separated due to corroded bolts.

The strainer has been leaking slowly for months. Workers pumped the bilge regularly, which became a ‘normal’ process.

The work order to repair the strainer was considered low priority, so had not been actioned.

The alarm was stopped several times without investigation, and not investigated until a secondary warning alarm was raised.

The valve was classed as ‘non-critical’ and had no regular inspection regime.

No regular maintenance scheme in place to look at strainers, seals and the UV on the piping systems for sea water.

What did they learn?

Make sure that all alarms are investigated – a regular alarm is not ‘normal’.

Implement inspections and maintenance regimes for marine systems equipment such as strainers bolting, seals replacement (bottom strainer with plate off), and piping system for sea water.

Ensure that all work orders are looked at, even if they do not seem to be safety critical.

Ask yourself or your crew

What is the worst that could have happened?

Are you operating pieces of equipment using workarounds that have become ‘normal’?

Is your maintenance program adequate (frequency, type of checks)? Does it cover all necessary equipment and areas (such as marine systems)?

Are all alarms identified and checked to confirm that action is taken as necessary?

What measures do we have in place to prevent this from happening here? How can we improve?

A tension leg platform (TLP) column flooded due to sea water lift (SWL) strainer bottom plate rupture.