-

What happened?

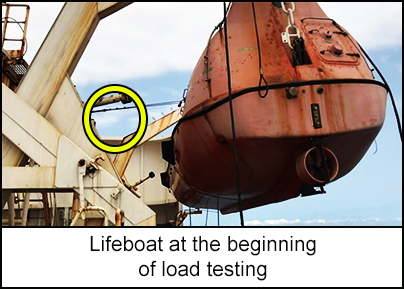

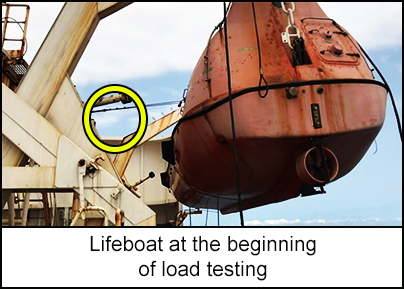

An unmanned lifeboat was being load tested.

Initial dynamic tests of the lifeboat being raised and lowered without a load were successful.

The lifeboat was then loaded with water bags and the load test began.

The forward davit fall wire rope failed at the dead end termination.

The lifeboat’s forward end fell, transferring its full weight to the aft davit.

The lifeboat hull failed at the aft hook and the lifeboat fell into the sea.

No one was injured, but the incident had potential for multiple fatalities.

-

Why did it happen?

The davit fall wire rope at the dead end termination slipped through three U-bolt wire rope clips and around the termination thimble.

- The U-bolts, thimbles and turnbuckle had not been replaced for 12 years since the boat was in use, despite regular preventative maintenance on thelifeboat. Fall wires replaced twice in 12 years.

- The U-bolt clips installation was incorrect (incorrect spacing, not re-torqued).

- Newer lifeboat installations were instructed not to use U-bolt clips, but this was not retrospectively applied to older ones.

Gaps in contractor management for testing of lifeboat (Contractor performing lifeboat maintenance and testing not on approved vendor list;

inadequate operator oversight during work;

only one contractor crew member certified by Class Society;

No defined work scope provided to contractor and contractor work plan inadequate (e.g., no work plan to verify appropriate weight distribution within lifeboat or for accurate weight calculation – failed to account for use of seawater vs fresh water)

Gaps in contractor management for lifeboat maintenance and testing:

- Not on an approved vendor list.

- Just one contractor crew member was certified.

- Inadequate supervision during work.

- No work plan to verify weight distribution within lifeboat or accurate weight calculation – failed to account for use of seawater vs fresh water.

Pre-use checks noted that there was movement in the aft hook, and fibreglass cracks were observed. The original equipment manufacturer (OEM advised) it shouldn’t be a problem.

-

What did they learn?

Consider using wedge sockets or permanent terminations instead of wire rope clips for the davit fall wire rope termination.

Make sure that lifeboats have a secondary holding source to allow worker entry in non-emergency situations.

Ensure all lifeboats are up-to-date with inspection requirements and those servicing them are trained and authorised.

Ensure lifeboat preventative maintenance is conducted regularly and in accordance with manufacturer requirements.

-

Ask yourself or your crew

Has anything like this ever happened on your vessel?

What tests do you run during lifeboat inspections?

What is the weight difference between saltwater and fresh water performing weight calculations?

How do we know that lifeboats and equipment have been maintained properly?

What should you do if you are unsure of the procedures for today’s load testing job?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An unmanned lifeboat was being load tested.

Initial dynamic tests of the lifeboat being raised and lowered without a load were successful.

The lifeboat was then loaded with water bags and the load test began.

The forward davit fall wire rope failed at the dead end termination.

The lifeboat’s forward end fell, transferring its full weight to the aft davit.

The lifeboat hull failed at the aft hook and the lifeboat fell into the sea.

No one was injured, but the incident had potential for multiple fatalities.

Why did it happen?

The davit fall wire rope at the dead end termination slipped through three U-bolt wire rope clips and around the termination thimble.

- The U-bolts, thimbles and turnbuckle had not been replaced for 12 years since the boat was in use, despite regular preventative maintenance on thelifeboat. Fall wires replaced twice in 12 years.

- The U-bolt clips installation was incorrect (incorrect spacing, not re-torqued).

- Newer lifeboat installations were instructed not to use U-bolt clips, but this was not retrospectively applied to older ones.

Gaps in contractor management for testing of lifeboat (Contractor performing lifeboat maintenance and testing not on approved vendor list;

inadequate operator oversight during work;

only one contractor crew member certified by Class Society;

No defined work scope provided to contractor and contractor work plan inadequate (e.g., no work plan to verify appropriate weight distribution within lifeboat or for accurate weight calculation – failed to account for use of seawater vs fresh water)

Gaps in contractor management for lifeboat maintenance and testing:

- Not on an approved vendor list.

- Just one contractor crew member was certified.

- Inadequate supervision during work.

- No work plan to verify weight distribution within lifeboat or accurate weight calculation – failed to account for use of seawater vs fresh water.

Pre-use checks noted that there was movement in the aft hook, and fibreglass cracks were observed. The original equipment manufacturer (OEM advised) it shouldn’t be a problem.

What did they learn?

Consider using wedge sockets or permanent terminations instead of wire rope clips for the davit fall wire rope termination.

Make sure that lifeboats have a secondary holding source to allow worker entry in non-emergency situations.

Ensure all lifeboats are up-to-date with inspection requirements and those servicing them are trained and authorised.

Ensure lifeboat preventative maintenance is conducted regularly and in accordance with manufacturer requirements.

Ask yourself or your crew

Has anything like this ever happened on your vessel?

What tests do you run during lifeboat inspections?

What is the weight difference between saltwater and fresh water performing weight calculations?

How do we know that lifeboats and equipment have been maintained properly?

What should you do if you are unsure of the procedures for today’s load testing job?

During the load testing of an unmanned lifeboat, the forward davit fall wire rope failed at the dead end termination, allowing the lifeboat forward end to fall. The lifeboat hull failed at the aft hook, and lifeboat fell to sea. The incident had potential for multiple fatalities.