-

What happened?

A control valve loop had thinned and was taken out of service.

It needed to be purged with flushing oil.Two workers remained to do the work, while non-essential personnel left the area.

The locks listed in the energy isolation device list were counted and removed, but the 3 ‘try’ points were not verified.

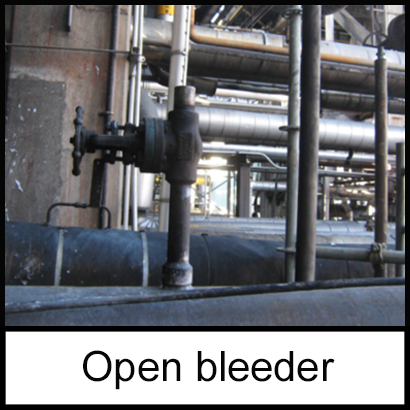

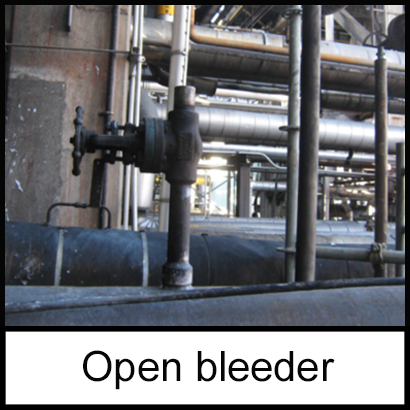

A high point bleeder vent was not blocked before introducing the flushing oil, causing a fire.

-

Why did it happen?

The operators assumed the only open bleeders were the two low point bleeders.

They did not verify all three were blocked.

Unclear responsibilities: neither operator thought they were responsible for ensuring try points were verified.

-

What did they learn?

We cannot assume that bleeder valves are blocked. They must be verified.

Low and high points documented on the equipment isolation device list must be checked throughout the whole system.

Where several workers are involved, make it clear who is accountable for what part of the task.

-

Ask yourself or your crew

What other actions could have been taken?

Why do you think these workers did what they did?

How could this have happened here?

How do we ensure that all the try points are being verified?

How do we assign responsibilities when several people are involved in a task?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A control valve loop had thinned and was taken out of service.

It needed to be purged with flushing oil.Two workers remained to do the work, while non-essential personnel left the area.

The locks listed in the energy isolation device list were counted and removed, but the 3 ‘try’ points were not verified.

A high point bleeder vent was not blocked before introducing the flushing oil, causing a fire.

Why did it happen?

The operators assumed the only open bleeders were the two low point bleeders.

They did not verify all three were blocked.

Unclear responsibilities: neither operator thought they were responsible for ensuring try points were verified.

What did they learn?

We cannot assume that bleeder valves are blocked. They must be verified.

Low and high points documented on the equipment isolation device list must be checked throughout the whole system.

Where several workers are involved, make it clear who is accountable for what part of the task.

Ask yourself or your crew

What other actions could have been taken?

Why do you think these workers did what they did?

How could this have happened here?

How do we ensure that all the try points are being verified?

How do we assign responsibilities when several people are involved in a task?

A coker control valve loop was taken out of service due to thinning. A high point bleeder vent was not blocked before introducing the flushing oil, causing a fire.