-

What happened?

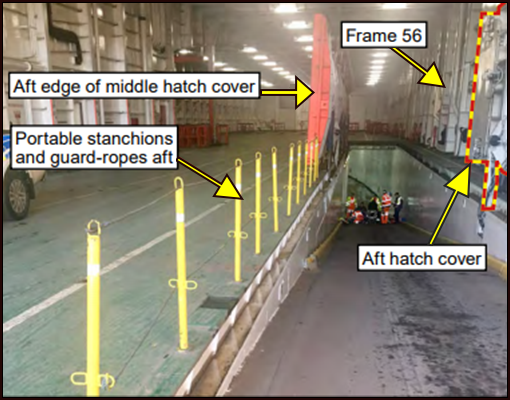

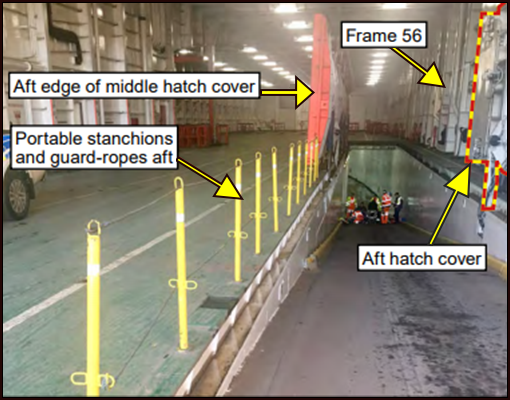

A crew member was working alone and preparing to paint the leading edge of the open ramp hatch cover.

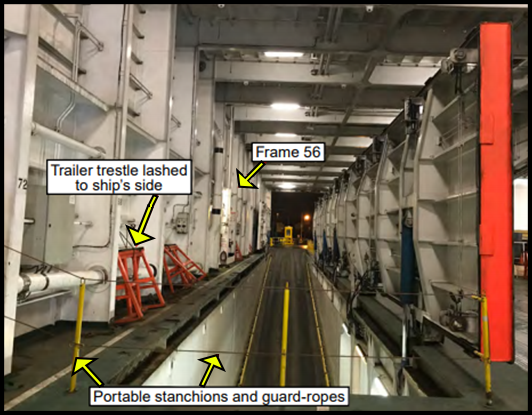

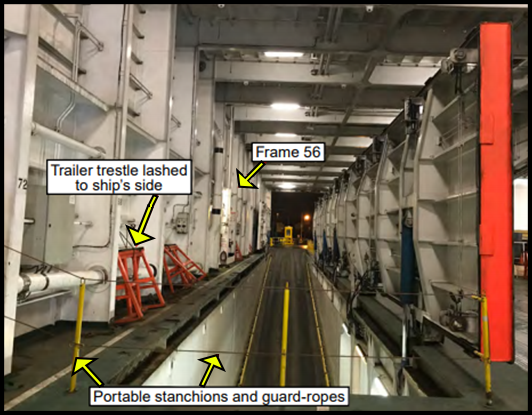

For unknown reasons, the crewman crossed a temporary safety barrier guarding the edge of the open hatch and walked along a narrow deck edge between the ship’s side and the open hatch on which several trailer trestles were stowed.

The crew member fell 4.5 metres (15 feet). The fall was not witnessed but it was evident that he had fallen at or about the same time as one of the trestles.

The crew member was treated at the scene before being taken to hospital, but died three days later.

-

Why did it happen?

The crew member crossed a safety barrier protecting an open hatch.

Risk was seen as tolerable – the risk of falling was accepted.

Work practices indicated that adherence to the vessel’s safety procedures was based on routine, rather than of understanding and conviction.

-

What did they learn?

Remind ship masters of dangers of bypassing safety control measures and prompt review of safety deck openings.

Provide safety chains, fittings and warning signs for use on the temporary barriers rigged on the main vehicle decks of ferries.

Review risk assessments, permit to work (PTW) concerning working at height and introduce a procedure for recording the use of safety harnesses.

Engage masters, safety officers and senior management with surveys and send them on safety courses.

Engage HSE consultants with the aim of forming a safety culture steering group and implementing a ‘safety climate tool’.

-

Ask yourself or your crew

Why do you think the crew member bypassed the safety control in this situation?

Would you need to bypass safety controls in your workplace? How can we change the task to avoid this?

What working at height controls do we have in place? How can they be improved?

How effective is your safety culture where you work?

Would you say we have a ‘low’ safety culture or a ‘high’ one? Why?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A crew member was working alone and preparing to paint the leading edge of the open ramp hatch cover.

For unknown reasons, the crewman crossed a temporary safety barrier guarding the edge of the open hatch and walked along a narrow deck edge between the ship’s side and the open hatch on which several trailer trestles were stowed.

The crew member fell 4.5 metres (15 feet). The fall was not witnessed but it was evident that he had fallen at or about the same time as one of the trestles.

The crew member was treated at the scene before being taken to hospital, but died three days later.

Why did it happen?

The crew member crossed a safety barrier protecting an open hatch.

Risk was seen as tolerable – the risk of falling was accepted.

Work practices indicated that adherence to the vessel’s safety procedures was based on routine, rather than of understanding and conviction.

What did they learn?

Remind ship masters of dangers of bypassing safety control measures and prompt review of safety deck openings.

Provide safety chains, fittings and warning signs for use on the temporary barriers rigged on the main vehicle decks of ferries.

Review risk assessments, permit to work (PTW) concerning working at height and introduce a procedure for recording the use of safety harnesses.

Engage masters, safety officers and senior management with surveys and send them on safety courses.

Engage HSE consultants with the aim of forming a safety culture steering group and implementing a ‘safety climate tool’.

Ask yourself or your crew

Why do you think the crew member bypassed the safety control in this situation?

Would you need to bypass safety controls in your workplace? How can we change the task to avoid this?

What working at height controls do we have in place? How can they be improved?

How effective is your safety culture where you work?

Would you say we have a ‘low’ safety culture or a ‘high’ one? Why?

A crew member died as a result of 4.5 metres fall through a vehicle ramp hatch.