-

What happened?

A diving support vessel (DSV) was working on preparation to install a closing spool.

Three DMAs were being deployed to use static and mechanical hold backs attached to the spool.

Two deadman anchors (DMAs) were deployed by the DSV.

A third DMA had previously been deployed and wet stored by a third party vessel.

The DSV arriving on site found the DMA3 in the ‘correct’ location, so they used it instead of the DMA on the dive plan. Holdbacks were attached.

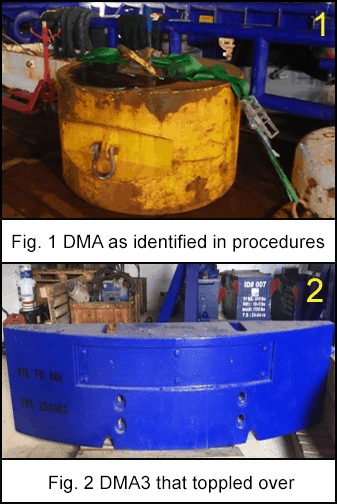

As a diver took up the slack in the rigging, it toppled over, trapping their leg on the seabed.

Another diver helped to free them, and they were recovered to the surface.

The diver suffered a fractured leg and torn ankle ligament.

-

Why did it happen?

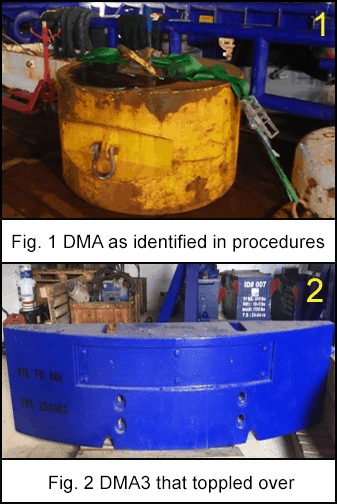

DMA that toppled over was different in weight and design from the one in the procedure.

- The lifting points on DMA3 were located on the top of the weight and it could only be deployed in the vertical position, offering a small footprint and high centre of gravity.

- The rigging arrangement placed the diver in close proximity to the DMA during attachment, adjustment and detachment.

Degree of complacency and poor perception of risk among all involved parties:

- Dive team used the incorrect DMA deployed by the third party.

- No checks have been made to determine if DMA3 was fit for purpose before starting the job.

- Management of change (MoC) procedure was not initiated, and the risk of toppling has not been identified.

- The safe system of work should have compensated for inadequate equipment and stopped operations before the incident occurred.

Existing procedures and risk assessments for the use of subsea DMAs were too generic.

-

What did they learn?

DMA rigging should be altered to allow divers to be outside of the DMA footprint.

Review company documentation, procedures and management of change (MoC) process. Include DMA design specification and diver positioning in the documentation.

Place a bigger focus on behaviours and task supervision.

-

Ask yourself or your crew

When would you have stopped work in this incident?

How can you ensure that the correct equipment is used during your operations?

How do you know if the procedures and risk assessments are specific enough for your tasks? What should you if something has been missed?

What is your management of change process?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A diving support vessel (DSV) was working on preparation to install a closing spool.

Three DMAs were being deployed to use static and mechanical hold backs attached to the spool.

Two deadman anchors (DMAs) were deployed by the DSV.

A third DMA had previously been deployed and wet stored by a third party vessel.

The DSV arriving on site found the DMA3 in the ‘correct’ location, so they used it instead of the DMA on the dive plan. Holdbacks were attached.

As a diver took up the slack in the rigging, it toppled over, trapping their leg on the seabed.

Another diver helped to free them, and they were recovered to the surface.

The diver suffered a fractured leg and torn ankle ligament.

Why did it happen?

DMA that toppled over was different in weight and design from the one in the procedure.

- The lifting points on DMA3 were located on the top of the weight and it could only be deployed in the vertical position, offering a small footprint and high centre of gravity.

- The rigging arrangement placed the diver in close proximity to the DMA during attachment, adjustment and detachment.

Degree of complacency and poor perception of risk among all involved parties:

- Dive team used the incorrect DMA deployed by the third party.

- No checks have been made to determine if DMA3 was fit for purpose before starting the job.

- Management of change (MoC) procedure was not initiated, and the risk of toppling has not been identified.

- The safe system of work should have compensated for inadequate equipment and stopped operations before the incident occurred.

Existing procedures and risk assessments for the use of subsea DMAs were too generic.

What did they learn?

DMA rigging should be altered to allow divers to be outside of the DMA footprint.

Review company documentation, procedures and management of change (MoC) process. Include DMA design specification and diver positioning in the documentation.

Place a bigger focus on behaviours and task supervision.

Ask yourself or your crew

When would you have stopped work in this incident?

How can you ensure that the correct equipment is used during your operations?

How do you know if the procedures and risk assessments are specific enough for your tasks? What should you if something has been missed?

What is your management of change process?

Diving support vessels (DSVs) were deploying deadman anchors (DMAs). Two were deployed successfully, but a third incorrect one was mistakenly used and when being deployed, toppled over and trapped a diver.