-

What happened?

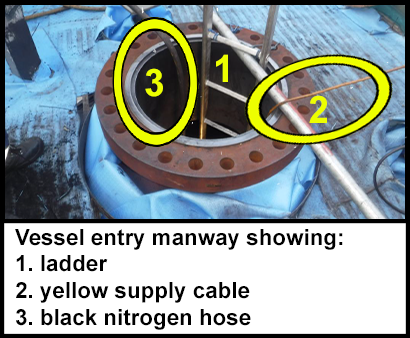

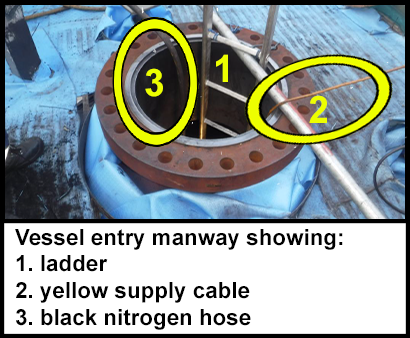

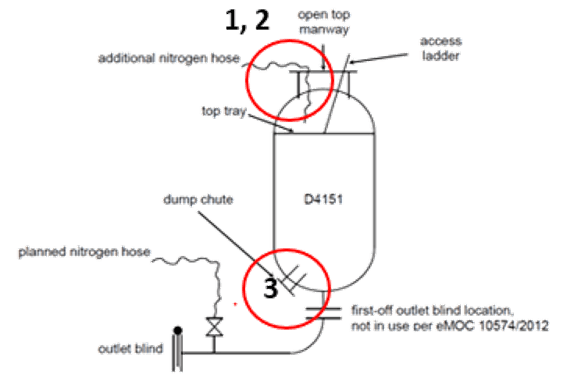

A second nitrogen hose was added through the top vessel manway to accelerate a catalyst change in an inert environment operation.

The hose was not recorded on any permit-to-work or communicated to relevant personnel.

The hose was accidentally left in place when the inert work was complete.

The pre-entry gas test did not identify a low oxygen environment.

A worker’s personal oxygen monitor read 16% when he entered to clean the top catalyst trays.

The worker safely exited the vessel.

-

Why did it happen?

1. The secondary nitrogen hose was NOT:

- in the plan

- documented in the permit-to-work, or

- communicated to the relevant personnel

2. A low oxygen environment was created when work was completed, but the hose was not isolated, disconnected or removed.

- The pre-entry gas test did not give an accurate reading as it was carried out at the dump chute, not at the vessel entry point.

- The permit to work to allow entry into the vessel was based on the inaccurate gas test results.

-

What did they learn?

All additional changes that might alter the working environment must be communicated to relevant personnel and registered in the permit to work.

Atmospheric gas tests must be done at the correct points.

An entry point attendant must be on stand-by when the confined space operation is ongoing.

-

Ask yourself or your crew

What other actions could have been taken?

How could something similar happen on our site?

Give an example of when we made a modification and did not record this in the permit to work.

How do we know we are conducting atmospheric gas tests at the right location?

What improvements can we make to how we work today?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A second nitrogen hose was added through the top vessel manway to accelerate a catalyst change in an inert environment operation.

The hose was not recorded on any permit-to-work or communicated to relevant personnel.

The hose was accidentally left in place when the inert work was complete.

The pre-entry gas test did not identify a low oxygen environment.

A worker’s personal oxygen monitor read 16% when he entered to clean the top catalyst trays.

The worker safely exited the vessel.

Why did it happen?

1. The secondary nitrogen hose was NOT:

- in the plan

- documented in the permit-to-work, or

- communicated to the relevant personnel

2. A low oxygen environment was created when work was completed, but the hose was not isolated, disconnected or removed.

- The pre-entry gas test did not give an accurate reading as it was carried out at the dump chute, not at the vessel entry point.

- The permit to work to allow entry into the vessel was based on the inaccurate gas test results.

What did they learn?

All additional changes that might alter the working environment must be communicated to relevant personnel and registered in the permit to work.

Atmospheric gas tests must be done at the correct points.

An entry point attendant must be on stand-by when the confined space operation is ongoing.

Ask yourself or your crew

What other actions could have been taken?

How could something similar happen on our site?

Give an example of when we made a modification and did not record this in the permit to work.

How do we know we are conducting atmospheric gas tests at the right location?

What improvements can we make to how we work today?

The pre-entry gas test did not identify a low oxygen environment. A worker’s personal oxygen monitor read 16.% when he entered to clean the top catalyst trays.