-

What happened?

A platform supply vessel (PSV) was on standby near an offshore installation.

PSV was pitching and rolling heavily due to bad weather conditions.

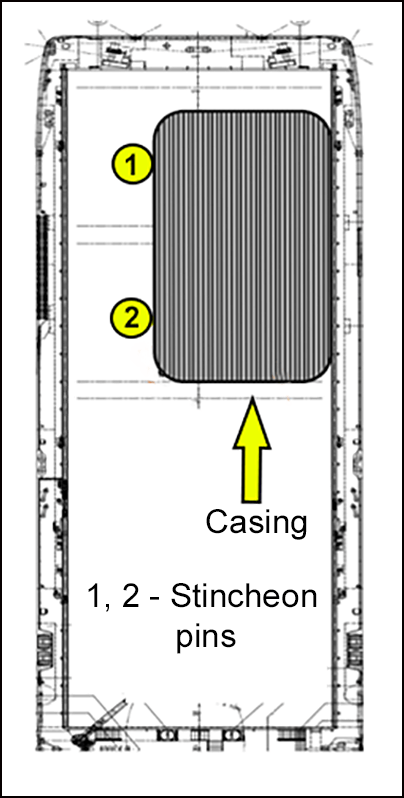

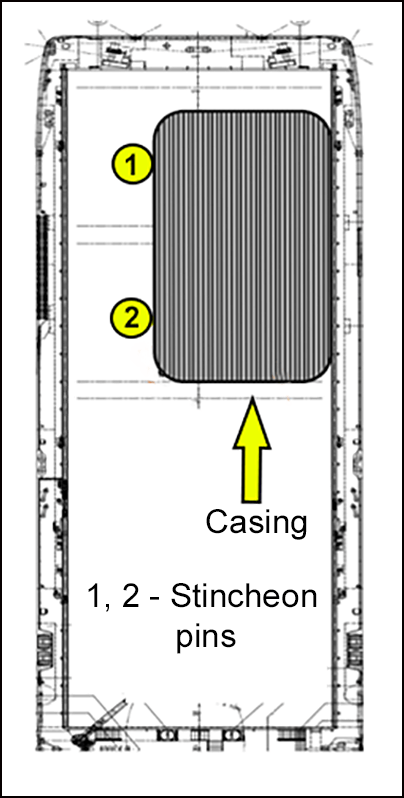

A load of 0.5m (20in) casing was covering two-thirds of the deck on the port side. It was stacked two layers high and secured with pipe stanchion pins.

PSV rolled to the starboard side and the pipe stanchions sheared.

Load moved 3m (10ft) starboard and ended up resting against other cargo.

No personnel were on deck at the time due to adverse weather conditions, thus no injuries occurred.

-

Why did it happen?

Both stanchion pins sheared at the base/weld.

Poor planning and incorrect securing method:

- 10–15cm (4-6in) gap between forward pin and casing allowed movement.

- This resulted in extra load on the aft pin when the vessel was rolling, causing the aft pin to shear.

Bad weather and sea conditions - wind 45 knots, sea state 5-6m/16-19ft.

- Crane operations were suspended due to excessive wind.

- This meant that the loads could not have been boxed in.

Inadequate inspection:

- Most recent visual inspection took place within 3 months before the incident. Pins were found to be in satisfactory condition.

- It was later identified that pins were several years old and had been in use frequently during adverse weather.

-

What did they learn?

Increase focus on load/backload planning and placement of equipment on deck.

- Consider boxing in loads with heavier cargo.

Assess the life span of securing pins - inspect and replace pins as required.

Ensure welds are subject to non-destructive examination (NDE).

Evaluate whether additional stanchion pins are needed in winter periods during loading/backloading.

-

Ask yourself or your crew

What is your testing/maintenance regime for stanchion pins?

- Is visual inspection enough?

- What other inspection/testing methods should we perform?

What is your loading/backloading procedure?

- When should you consider boxing in loads?

What extra precautions will you need to take if weather conditions change for the worse today?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A platform supply vessel (PSV) was on standby near an offshore installation.

PSV was pitching and rolling heavily due to bad weather conditions.

A load of 0.5m (20in) casing was covering two-thirds of the deck on the port side. It was stacked two layers high and secured with pipe stanchion pins.

PSV rolled to the starboard side and the pipe stanchions sheared.

Load moved 3m (10ft) starboard and ended up resting against other cargo.

No personnel were on deck at the time due to adverse weather conditions, thus no injuries occurred.

Why did it happen?

Both stanchion pins sheared at the base/weld.

Poor planning and incorrect securing method:

- 10–15cm (4-6in) gap between forward pin and casing allowed movement.

- This resulted in extra load on the aft pin when the vessel was rolling, causing the aft pin to shear.

Bad weather and sea conditions - wind 45 knots, sea state 5-6m/16-19ft.

- Crane operations were suspended due to excessive wind.

- This meant that the loads could not have been boxed in.

Inadequate inspection:

- Most recent visual inspection took place within 3 months before the incident. Pins were found to be in satisfactory condition.

- It was later identified that pins were several years old and had been in use frequently during adverse weather.

What did they learn?

Increase focus on load/backload planning and placement of equipment on deck.

- Consider boxing in loads with heavier cargo.

Assess the life span of securing pins - inspect and replace pins as required.

Ensure welds are subject to non-destructive examination (NDE).

Evaluate whether additional stanchion pins are needed in winter periods during loading/backloading.

Ask yourself or your crew

What is your testing/maintenance regime for stanchion pins?

- Is visual inspection enough?

- What other inspection/testing methods should we perform?

What is your loading/backloading procedure?

- When should you consider boxing in loads?

What extra precautions will you need to take if weather conditions change for the worse today?

A platform supply vessel (PSV) was loaded with 0.5m (20in) casing secured with stanchion pins. Due to bad weather, PSV was rolling and pitching heavily. The pipe stanchions sheared, allowing the load to move 3m (10ft) and ending up resting against other cargo.