-

What happened?

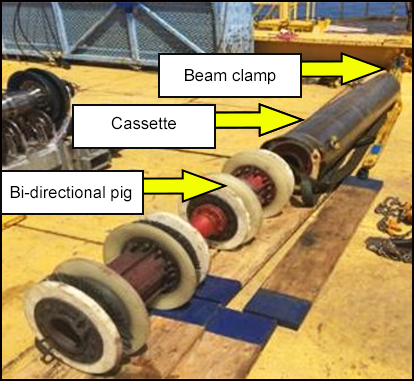

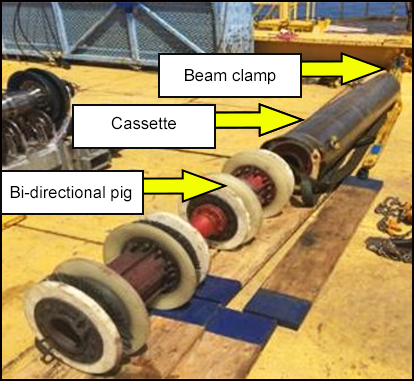

A team was conducting an in-line inspection of a 16-inch pipeline.

The team attempted twice to load the bi-directional cleaning pig into the vertical pig launcher but failed. The work was stopped.

Later, they decided to insert the pig into a cassette (large pipe) that was to be used as a guide to load the pig into the pig launcher. This was not included in the original job safety planning.

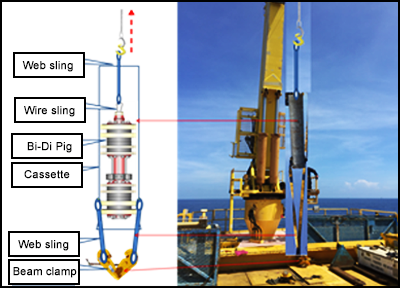

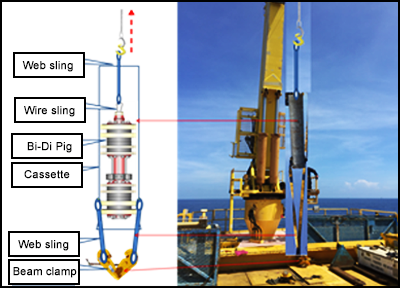

To avoid further delays, the team used a platform crane to insert the pig into the cassette, instead of the typically used chain hoist. They tied the cassette to the platform beam using 2 slings.

1 of the slings parted, resulting in the pig and the cassette (140 kilograms) falling 1.8 meters/6 feet onto the deck.

There were no injuries. The nearest person was approximately 2 metres away from the location of the dropped object.

-

Why did it happen?

Leadership accountability – deviation accepted:

- Team deviated from the scope of the planned work.

- This was due to the unsuccessful attempts to follow the original plan.

Inadequate operating procedures:

- The team followed an inadequate procedure for inserting the pig into the cassette.

Hazard not recognised:

- The hazards associated with using the crane instead of a chain hoist were not recognised by the team.

-

What did they learn?

Specific procedures and risk assessments for high-risk jobs, such as loading a pig into a vertical or horizontal pig launcher, should be developed and in place.

The procedure, hazard analysis, and/or job safety analysis should identify all critical steps; especially troubleshooting and contingency plans.

Supervisors and/or persons leading work should conduct job site verification and validation to ensure work procedures are in place, understood, and used by work teams for critical and less frequent tasks.

-

Ask yourself or your crew

How can something like this happen here?

Describe the process for correctly loading a pig. What should we do if this doesn’t work?

How do we verify if the management of change (MOC) is followed when the task changes?

If we had such an incident and someone was hurt, what should we do?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A team was conducting an in-line inspection of a 16-inch pipeline.

The team attempted twice to load the bi-directional cleaning pig into the vertical pig launcher but failed. The work was stopped.

Later, they decided to insert the pig into a cassette (large pipe) that was to be used as a guide to load the pig into the pig launcher. This was not included in the original job safety planning.

To avoid further delays, the team used a platform crane to insert the pig into the cassette, instead of the typically used chain hoist. They tied the cassette to the platform beam using 2 slings.

1 of the slings parted, resulting in the pig and the cassette (140 kilograms) falling 1.8 meters/6 feet onto the deck.

There were no injuries. The nearest person was approximately 2 metres away from the location of the dropped object.

Why did it happen?

Leadership accountability – deviation accepted:

- Team deviated from the scope of the planned work.

- This was due to the unsuccessful attempts to follow the original plan.

Inadequate operating procedures:

- The team followed an inadequate procedure for inserting the pig into the cassette.

Hazard not recognised:

- The hazards associated with using the crane instead of a chain hoist were not recognised by the team.

What did they learn?

Specific procedures and risk assessments for high-risk jobs, such as loading a pig into a vertical or horizontal pig launcher, should be developed and in place.

The procedure, hazard analysis, and/or job safety analysis should identify all critical steps; especially troubleshooting and contingency plans.

Supervisors and/or persons leading work should conduct job site verification and validation to ensure work procedures are in place, understood, and used by work teams for critical and less frequent tasks.

Ask yourself or your crew

How can something like this happen here?

Describe the process for correctly loading a pig. What should we do if this doesn’t work?

How do we verify if the management of change (MOC) is followed when the task changes?

If we had such an incident and someone was hurt, what should we do?

A team was conducting an in-line inspection of a 16-inch pipeline. The crew deviated from the scope of the planned work and did not assess the hazards associated with the new plan. An object dropped from a height of 1.8 metres. Nobody was hurt as the nearest workers was 2 metres away, but the incident had high potential.