-

What happened?

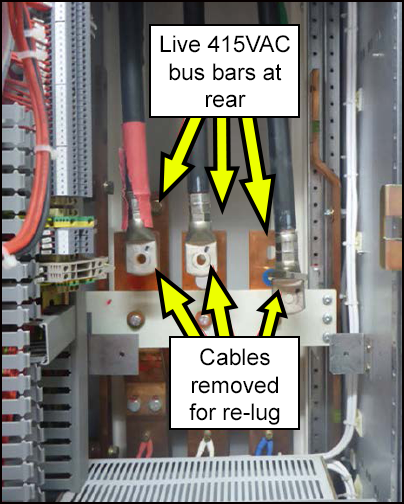

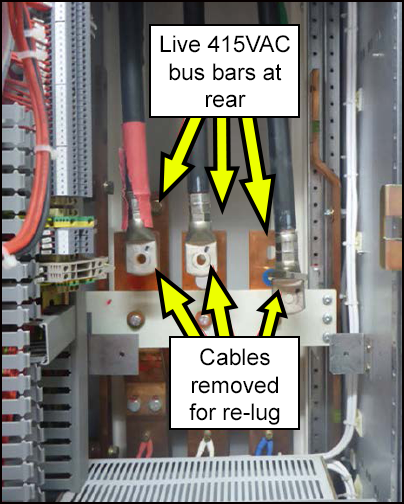

As part of an electrical transformer upgrade, new mains cables were run to a 415V electrical switchboard.

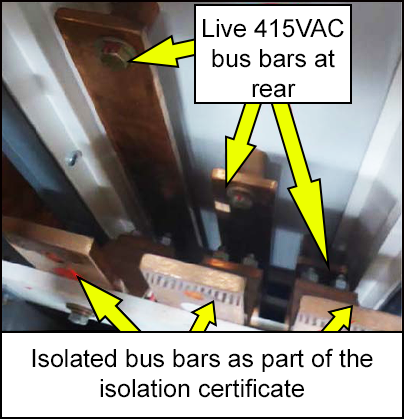

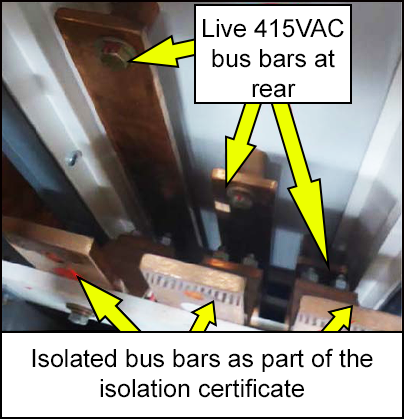

The transformer, electrical switchboard circuit breaker and lineside bus bars were isolated and proved de-energised.

When unbolting the existing main cables, the second set of bus bars were discovered behind the isolated equipment, at varying lengths.

Rear bus bars were tested and found live (240V / 415V a.c.), with a significant potential of electric shock.

-

Why did it happen?

No segregation was installed between line and load side bus bars.

The proximity of load and line side bus bars was not identified when engineering the back-feed, designed to keep essential services operational in the admin building.

Electrical drawings were not readily available.

Confidence in the permitting process contributed to an assumed degree of safety, resulting in a reduced level of awareness for unidentified hazards.

The test for dead was running on cables at the transformer end. Only the parts to be worked on were tested for dead.

The permit did not consider the rear bars as intrusive work, so it was assumed that all bus bars were de-energised.

-

What did they learn?

Install warning signs on all switchboards with similar arrangements.

Where feasible, install full segregation between line side terminals and load side bus bar transition sections.

Ensure workers understand the job and its hazards during work pack preparation. Obtain and ensure accuracy of all switchboard general arrangement drawings.

Holding a work permit does not guarantee that the job is hazard-free.

‘Testing for dead’ confirms isolations and identifies potential exposures. ‘Testing for life’ is more useful when investigating the possibility of live adjacent equipment.

Update management of change process to ensure changes are fully assessed, captured, documented and communicated.

-

Ask yourself or your crew

How can something like this happen here?

What could have happened if the second set of live bus bars would not have been identified and work continued?

How do you know if the system is de-energised before starting work?

How do you know whether adjacent systems are live and whether they pose a danger?

What ‘unseen’ hazards might there be in today’s electrical task? How do you know?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

As part of an electrical transformer upgrade, new mains cables were run to a 415V electrical switchboard.

The transformer, electrical switchboard circuit breaker and lineside bus bars were isolated and proved de-energised.

When unbolting the existing main cables, the second set of bus bars were discovered behind the isolated equipment, at varying lengths.

Rear bus bars were tested and found live (240V / 415V a.c.), with a significant potential of electric shock.

Why did it happen?

No segregation was installed between line and load side bus bars.

The proximity of load and line side bus bars was not identified when engineering the back-feed, designed to keep essential services operational in the admin building.

Electrical drawings were not readily available.

Confidence in the permitting process contributed to an assumed degree of safety, resulting in a reduced level of awareness for unidentified hazards.

The test for dead was running on cables at the transformer end. Only the parts to be worked on were tested for dead.

The permit did not consider the rear bars as intrusive work, so it was assumed that all bus bars were de-energised.

What did they learn?

Install warning signs on all switchboards with similar arrangements.

Where feasible, install full segregation between line side terminals and load side bus bar transition sections.

Ensure workers understand the job and its hazards during work pack preparation. Obtain and ensure accuracy of all switchboard general arrangement drawings.

Holding a work permit does not guarantee that the job is hazard-free.

‘Testing for dead’ confirms isolations and identifies potential exposures. ‘Testing for life’ is more useful when investigating the possibility of live adjacent equipment.

Update management of change process to ensure changes are fully assessed, captured, documented and communicated.

Ask yourself or your crew

How can something like this happen here?

What could have happened if the second set of live bus bars would not have been identified and work continued?

How do you know if the system is de-energised before starting work?

How do you know whether adjacent systems are live and whether they pose a danger?

What ‘unseen’ hazards might there be in today’s electrical task? How do you know?

As part of an electrical transformer upgrade, new mains cables were run to a 415V electrical switchboard. The electrical components were isolated and proven deenergised. During the task, a second set of live bus bars was discovered behind the isolated equipment.