-

What happened?

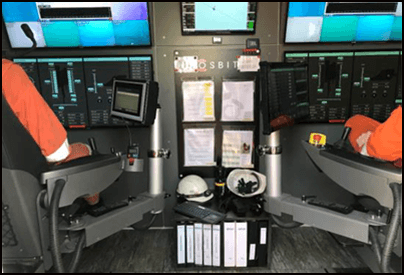

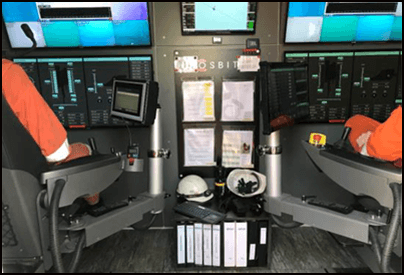

A remotely operated vehicle (ROV) was being used for offshore trenching operations.

The pilot accidentally knocked the joystick control, which operated the tool tilt function of the ROV.

The subsea trenching tool was lifted to 4 degrees. This raised the tool depth from 1.17 meters to 1.06 meters, resulting in the depressor depth being reduced.

This went unnoticed for 7 minutes while the shift handover was taking place and equated to 27 meters of travel.

While this did not present a risk to anyone, the learnings are applicable to other activities.

-

Why did it happen?

There were no controls to prevent the joystick from being activated (e.g. joystick lock, dead-man switch).

The tooling alarm tolerance range was too broad (-0.2° to +0.5°).

Trenching operations were not stopped during the shift handover.

No one noticed the change to the trencher angle – they were distracted as they were rebooting a crashed control computer at the same time as the shift handover.

-

What did they learn?

Ensure trenching operations are stopped during shift handovers – set operating panels to maintenance mode so the joysticks are deactivated.

Consider the method of handovers during live operations and the implications of reduced focus on the ongoing activities.

Review other equipment controls that could be inadvertently operated to prevent similar incidents.

Ensure that workers have all procedures, manuals and training needed to do their job safely.

-

Ask yourself or your crew

Are there any controls on your equipment that could be accidentally knocked without you knowing? What could the impact be of this?

How can we redesign or modify controls to prevent accidental activation? What process do we need to follow to do this?

Do you stop operations during shift handover?

- If not, should you?

- If this isn’t possible, how can you minimise the impact?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A remotely operated vehicle (ROV) was being used for offshore trenching operations.

The pilot accidentally knocked the joystick control, which operated the tool tilt function of the ROV.

The subsea trenching tool was lifted to 4 degrees. This raised the tool depth from 1.17 meters to 1.06 meters, resulting in the depressor depth being reduced.

This went unnoticed for 7 minutes while the shift handover was taking place and equated to 27 meters of travel.

While this did not present a risk to anyone, the learnings are applicable to other activities.

Why did it happen?

There were no controls to prevent the joystick from being activated (e.g. joystick lock, dead-man switch).

The tooling alarm tolerance range was too broad (-0.2° to +0.5°).

Trenching operations were not stopped during the shift handover.

No one noticed the change to the trencher angle – they were distracted as they were rebooting a crashed control computer at the same time as the shift handover.

What did they learn?

Ensure trenching operations are stopped during shift handovers – set operating panels to maintenance mode so the joysticks are deactivated.

Consider the method of handovers during live operations and the implications of reduced focus on the ongoing activities.

Review other equipment controls that could be inadvertently operated to prevent similar incidents.

Ensure that workers have all procedures, manuals and training needed to do their job safely.

Ask yourself or your crew

Are there any controls on your equipment that could be accidentally knocked without you knowing? What could the impact be of this?

How can we redesign or modify controls to prevent accidental activation? What process do we need to follow to do this?

Do you stop operations during shift handover?

- If not, should you?

- If this isn’t possible, how can you minimise the impact?

A remotely operated vehicle (ROV) was being used for offshore trenching operations. The pilot accidentally knocked the joystick control, which operated the tool tilt function of the ROV, raising the tool depth from 1.17m to 1.06m