-

What happened?

A vessel was in transit when smoke was noticed near the port main engine.

Smoke detection system activated, indicating smoke was in the engine room, and the general alarm sounded.

All personnel were mustered, and fire parties were prepared.

Port engine was brought to a controlled stop and its fuel supply was isolated.

Engineer identified that a fuel pipe connection had failed.

He reported to the bridge that there was slight smoke present in the engine room, but no fire.

Repairs were made, the engine run up and tested, and the transit continued.

-

Why did it happen?

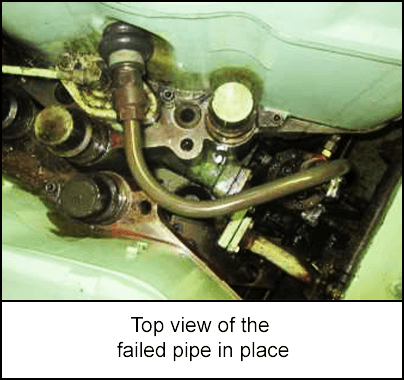

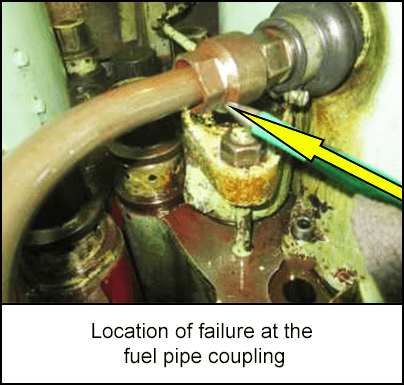

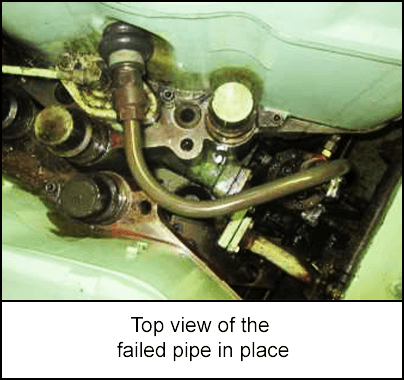

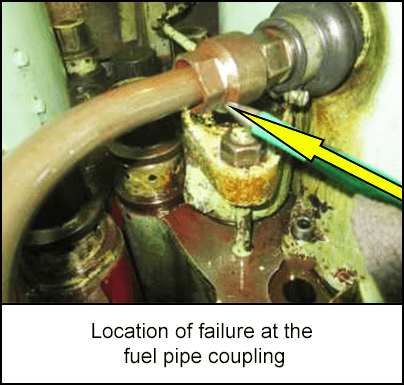

High-pressure fuel pipe coupling between the fuel injector and delivery pipe failed, causing fuel to run onto hot engine components and creating smoke.

- No signs of visible damage during inspection of the pipe.

Leak originated from the fuel coupling which contained an O-ring seal inside.

- Upon inspection the O ring was not brittle or damaged.

Engineer should have contacted the bridge immediately and start the shut-down of the port engine, but instead he called the second engineer to investigate.

Vessel crew had noticed a trend of failure of the fuel supply piping – this was the third failure in four months.

What went well:

Crew worked well to contain the incident quickly – identifying the source, stopping the engine, mustering correctly and returning the vessel to operation.

Use of original equipment manufacturer parts (and not suspect/reconditioned parts) allowed the crew to implement repairs quickly and effectively.

-

What did they learn?

Investigate similar systems to ensure there are no latent failures or defects that may cause a similar incident.

Ensure main engine fuel pump is overhauled to include fuel pipe pressure testing and seal renewals.

‘Know your ship’ – Personnel should have good awareness and knowledge of the equipment to be able to identify failed components swiftly and correctly.

-

Ask yourself or your crew

How would you and your fellow workers respond to an incident like this?

What should you do if you noticed a trend in equipment failing?

What is your inspection frequency of the engines on your vessel? What is included in the inspections?

What is your evacuation/muster procedure in case of an emergency?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A vessel was in transit when smoke was noticed near the port main engine.

Smoke detection system activated, indicating smoke was in the engine room, and the general alarm sounded.

All personnel were mustered, and fire parties were prepared.

Port engine was brought to a controlled stop and its fuel supply was isolated.

Engineer identified that a fuel pipe connection had failed.

He reported to the bridge that there was slight smoke present in the engine room, but no fire.

Repairs were made, the engine run up and tested, and the transit continued.

Why did it happen?

High-pressure fuel pipe coupling between the fuel injector and delivery pipe failed, causing fuel to run onto hot engine components and creating smoke.

- No signs of visible damage during inspection of the pipe.

Leak originated from the fuel coupling which contained an O-ring seal inside.

- Upon inspection the O ring was not brittle or damaged.

Engineer should have contacted the bridge immediately and start the shut-down of the port engine, but instead he called the second engineer to investigate.

Vessel crew had noticed a trend of failure of the fuel supply piping – this was the third failure in four months.

What went well:

Crew worked well to contain the incident quickly – identifying the source, stopping the engine, mustering correctly and returning the vessel to operation.

Use of original equipment manufacturer parts (and not suspect/reconditioned parts) allowed the crew to implement repairs quickly and effectively.

What did they learn?

Investigate similar systems to ensure there are no latent failures or defects that may cause a similar incident.

Ensure main engine fuel pump is overhauled to include fuel pipe pressure testing and seal renewals.

‘Know your ship’ – Personnel should have good awareness and knowledge of the equipment to be able to identify failed components swiftly and correctly.

Ask yourself or your crew

How would you and your fellow workers respond to an incident like this?

What should you do if you noticed a trend in equipment failing?

What is your inspection frequency of the engines on your vessel? What is included in the inspections?

What is your evacuation/muster procedure in case of an emergency?

A vessel was in transit when smoke was noticed near the port main engine. The fuel pipe connection had failed and caused fuel to run onto hot engine components which created smoke.