-

What happened?

7 miles of 8 inch diameter pipe was being replaced and hydrostatically tested.

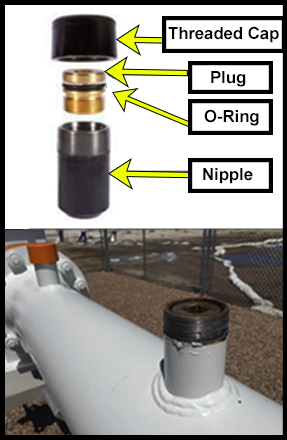

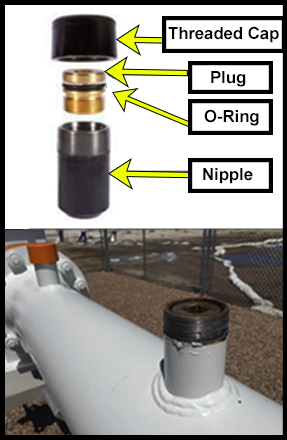

All threaded O-ring (TOR) caps were installed, but all plugs were removed, as this was how the person was trained to hydro-test TOR fittings.

Afterwards, TOR caps and plugs were reinstalled and pre-start up safety reviews performed on two out of three sections of piping.

A few weeks later a worker began removing the cap from another TOR fitting on the third section of piping.

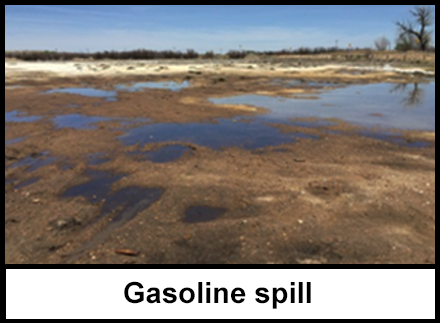

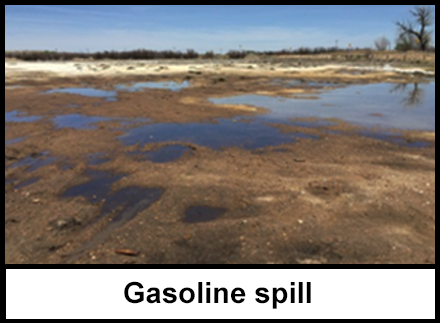

Gasoline started to leak from the cap’s threads and then the cap was propelled off by the gasoline.

The downstream valve was closed to stop the flow, and a plug was fitted, but not before 91 barrels of gasoline had leaked.

-

Why did it happen?

The TOR fitting on the third section of piping was missing a plug.

All plugs had been removed for hydro-testing, but not all had been reinstalled.

Pre-start up safety reviews were done for two sections of piping, but not the third.

-

What did they learn?

Pre-Start Up Safety Reviews (PSSR) must be conducted on all pipe sections.

Ensure all TOR fittings have plugs installed before any pipeline is put into service.

Confirm TOR fittings have plugs installed before removing caps.

-

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

What could have been the consequences of this incident?

Why might they have not completed pre-start up safety reviews on all sections of the pipe?

How do we ensure pre-start up safety reviews are 100% done?

How do we know that TOR fittings have plugs installed? How do we find out?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

7 miles of 8 inch diameter pipe was being replaced and hydrostatically tested.

All threaded O-ring (TOR) caps were installed, but all plugs were removed, as this was how the person was trained to hydro-test TOR fittings.

Afterwards, TOR caps and plugs were reinstalled and pre-start up safety reviews performed on two out of three sections of piping.

A few weeks later a worker began removing the cap from another TOR fitting on the third section of piping.

Gasoline started to leak from the cap’s threads and then the cap was propelled off by the gasoline.

The downstream valve was closed to stop the flow, and a plug was fitted, but not before 91 barrels of gasoline had leaked.

Why did it happen?

The TOR fitting on the third section of piping was missing a plug.

All plugs had been removed for hydro-testing, but not all had been reinstalled.

Pre-start up safety reviews were done for two sections of piping, but not the third.

What did they learn?

Pre-Start Up Safety Reviews (PSSR) must be conducted on all pipe sections.

Ensure all TOR fittings have plugs installed before any pipeline is put into service.

Confirm TOR fittings have plugs installed before removing caps.

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

What could have been the consequences of this incident?

Why might they have not completed pre-start up safety reviews on all sections of the pipe?

How do we ensure pre-start up safety reviews are 100% done?

How do we know that TOR fittings have plugs installed? How do we find out?

7 miles of 8 inch diameter pipe was being replaced and hydrostatically tested. Gasoline started to leak from the cap’s threads and then the cap was propelled off by the gasoline.