-

What happened?

An engineer was refilling a vessel’s central air conditioning (AC) system.

He closed the valves, disconnected the refrigerant gas bottle and started the motor to check for leaks.

The engineer crouched in front of the hose for a final torque and inadvertently opened the valve instead of tightening it.

The AC system started leaking refrigerant gas.

The engineer put one hand on the leak and tried to close the valve.

A colleague moved the engineer out of danger and closed the valve in a safe manner.

Once the frozen gloves had been removed, the engineer’s hands were placed in running water.

He received severe second-degree freezing burns to both hands, for which he was treated onboard until the following morning.

He was then transferred ashore for surgery and hospital treatment and was fit to return to work after a month of physiotherapy.

-

Why did it happen?

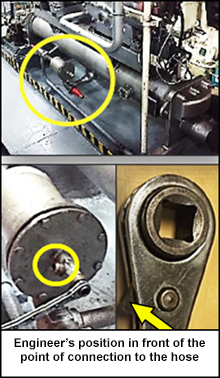

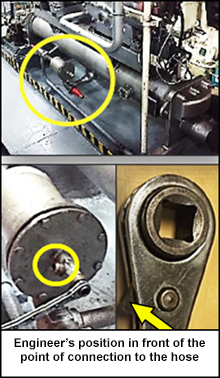

The engineer placed himself in the line of fire in front of the connection point of the hose.

The engineer did not check the torque direction of ratchet wrench before use and torqued the valve in the wrong direction.

The refrigerant gas used reaches temperatures of -46°C (-51F) when released. The engineer was wearing fabric gloves instead of the correct thermal protection gloves.

The material safety data sheets (MSDS) recommended the use of thermal protection gloves but there were none available.

There was no proper risk assessment nor job safety analysis (JSA) conducted for the task.

There was no awareness of the dangers involved.

The on-board vessel crew did not report the incident to shore in a timely manner.

-

What did they learn?

Rotate the position of the discharge point of the compressor so as not to point towards workers.

Use safety/retention valves on compressor discharge lines.

Ensure all workers are provided with specific thermal protection gloves.

Ensure there is training in job risk analysis, risk assessment and line of fire for all workers.

Permits to work (PTW) should be mandatory for work on high pressure equipment.

Reassess the use of chemicals onboard and their MSDS.

Ensure that incidents onboard vessels are reported to shore in a timely manner.

-

Ask yourself or your crew

Think about today’s job. How do you know where it is safe to be positioned when carrying out the task?

Are you fully aware of all the personal protective equipment (PPE) you should be wearing or using? How can you check before starting the job?

Have all the risks been considered in the risk assessment or JSA? What should you do if there’s any other risks that you can think of and need to be covered?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An engineer was refilling a vessel’s central air conditioning (AC) system.

He closed the valves, disconnected the refrigerant gas bottle and started the motor to check for leaks.

The engineer crouched in front of the hose for a final torque and inadvertently opened the valve instead of tightening it.

The AC system started leaking refrigerant gas.

The engineer put one hand on the leak and tried to close the valve.

A colleague moved the engineer out of danger and closed the valve in a safe manner.

Once the frozen gloves had been removed, the engineer’s hands were placed in running water.

He received severe second-degree freezing burns to both hands, for which he was treated onboard until the following morning.

He was then transferred ashore for surgery and hospital treatment and was fit to return to work after a month of physiotherapy.

Why did it happen?

The engineer placed himself in the line of fire in front of the connection point of the hose.

The engineer did not check the torque direction of ratchet wrench before use and torqued the valve in the wrong direction.

The refrigerant gas used reaches temperatures of -46°C (-51F) when released. The engineer was wearing fabric gloves instead of the correct thermal protection gloves.

The material safety data sheets (MSDS) recommended the use of thermal protection gloves but there were none available.

There was no proper risk assessment nor job safety analysis (JSA) conducted for the task.

There was no awareness of the dangers involved.

The on-board vessel crew did not report the incident to shore in a timely manner.

What did they learn?

Rotate the position of the discharge point of the compressor so as not to point towards workers.

Use safety/retention valves on compressor discharge lines.

Ensure all workers are provided with specific thermal protection gloves.

Ensure there is training in job risk analysis, risk assessment and line of fire for all workers.

Permits to work (PTW) should be mandatory for work on high pressure equipment.

Reassess the use of chemicals onboard and their MSDS.

Ensure that incidents onboard vessels are reported to shore in a timely manner.

Ask yourself or your crew

Think about today’s job. How do you know where it is safe to be positioned when carrying out the task?

Are you fully aware of all the personal protective equipment (PPE) you should be wearing or using? How can you check before starting the job?

Have all the risks been considered in the risk assessment or JSA? What should you do if there’s any other risks that you can think of and need to be covered?

An engineer was refilling a vessel’s central air conditioning (AC) system. He torqued the valve in the wrong direction and the refrigerant gas leaked from the valve, burning his hands.