-

What happened?

Two vessels were engaged in offshore ship-to-ship lifting operations.

A heavy lift crane was being used to lift a product reel from one vessel and land it on another.

To land the reel, ballasting was adjusted, changing the position of the crane boom.

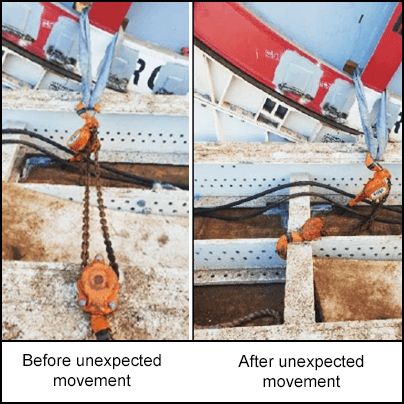

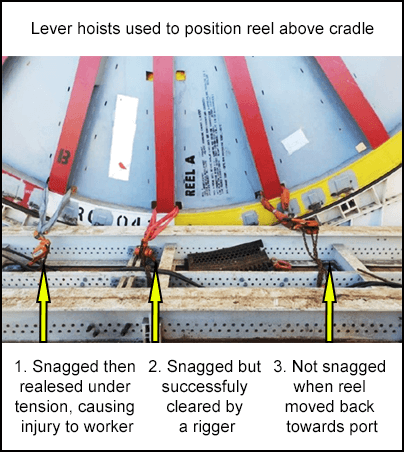

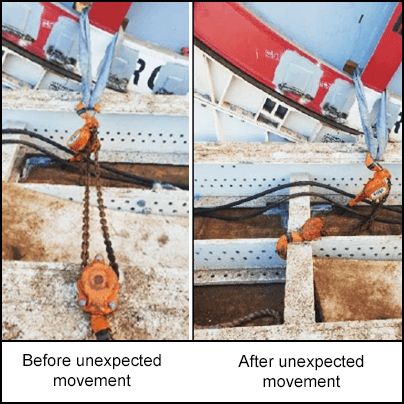

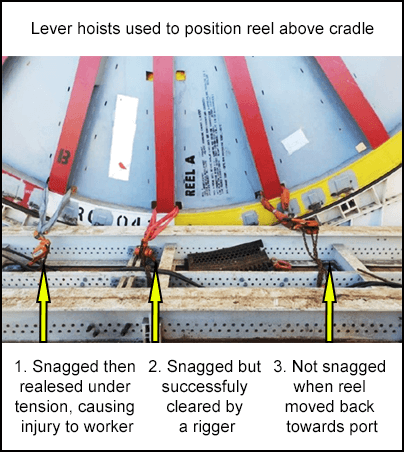

Riggers just connected three 6.3Te level hoists to the load to aid final positioning, when the load moved unexpectedly.

It swung 1.5m (5ft) towards them, allowing hoists to lose tension and disconnect.

The reel then moved back towards the port side, allowing two of the lever hoists to snag and come under tension.

Riggers disconnected one hoist, but tension on the second lever hoist became too great, resulting in the hook disengaging and striking the rigger’s hand.

The incident could have resulted in a serious injury or fatality.

-

Why did it happen?

The centre of gravity of the load was offset and not corrected.

Procedures and lift plans were not followed.

The introduction of lever hoists was not identified as a change, therefore a management of change (MoC) process was not triggered.

Lever hoists were not used in compliance with manufacturers guidance.

Ineffective communication between the banksman on the crane vessel and the rigging supervisor and riggers on the other vessel:

- They were using different radio channels.

- Ballasting operation was not communicated to the riggers.

Insufficient toolbox talk (TBT) and risk assessment for ‘line of fire’ hazards.

Workers may have put themselves at further risk by reacting without understanding the danger.

-

What did they learn?

Centre of gravity of a load should be confirmed and lift rigging adjusted accordingly before lifting starts.

Workers should keep clear of suspended loads until safely landed.

Any change from procedures or lift plans should be subject to a MoC process.

Clear lines of communication between workers involved in the lift are crucial and should be established before work starts.

Lever hoists may not be appropriate in a ship-to-ship operations – if they are used, it should be in line with manufacturer’s guidance.

-

Ask yourself or your crew

What could they have done differently?

What checks do you perform before starting a lifting operation?

How do you confirm the centre of gravity and adjust rigging accordingly before starting the job?

Who can trigger a management of change process and what are the steps involved?

How do you ensure all procedures and plans are followed?

What hazards should you look out for during lifting operations?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two vessels were engaged in offshore ship-to-ship lifting operations.

A heavy lift crane was being used to lift a product reel from one vessel and land it on another.

To land the reel, ballasting was adjusted, changing the position of the crane boom.

Riggers just connected three 6.3Te level hoists to the load to aid final positioning, when the load moved unexpectedly.

It swung 1.5m (5ft) towards them, allowing hoists to lose tension and disconnect.

The reel then moved back towards the port side, allowing two of the lever hoists to snag and come under tension.

Riggers disconnected one hoist, but tension on the second lever hoist became too great, resulting in the hook disengaging and striking the rigger’s hand.

The incident could have resulted in a serious injury or fatality.

Why did it happen?

The centre of gravity of the load was offset and not corrected.

Procedures and lift plans were not followed.

The introduction of lever hoists was not identified as a change, therefore a management of change (MoC) process was not triggered.

Lever hoists were not used in compliance with manufacturers guidance.

Ineffective communication between the banksman on the crane vessel and the rigging supervisor and riggers on the other vessel:

- They were using different radio channels.

- Ballasting operation was not communicated to the riggers.

Insufficient toolbox talk (TBT) and risk assessment for ‘line of fire’ hazards.

Workers may have put themselves at further risk by reacting without understanding the danger.

What did they learn?

Centre of gravity of a load should be confirmed and lift rigging adjusted accordingly before lifting starts.

Workers should keep clear of suspended loads until safely landed.

Any change from procedures or lift plans should be subject to a MoC process.

Clear lines of communication between workers involved in the lift are crucial and should be established before work starts.

Lever hoists may not be appropriate in a ship-to-ship operations – if they are used, it should be in line with manufacturer’s guidance.

Ask yourself or your crew

What could they have done differently?

What checks do you perform before starting a lifting operation?

How do you confirm the centre of gravity and adjust rigging accordingly before starting the job?

Who can trigger a management of change process and what are the steps involved?

How do you ensure all procedures and plans are followed?

What hazards should you look out for during lifting operations?

A heavy crane was being used to lift a product reel. The lever hoists snagged and one of them disengaged under tension, hitting a worker’s hand. The incident could have resulted in a serious injury or fatality.