-

What happened?

While using oil pumps, employee smelt burning from an electrical control panel.

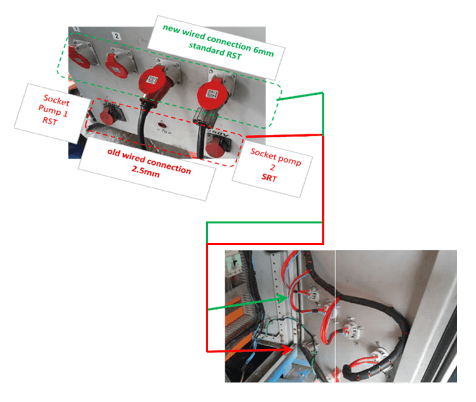

Inspection found that the panel used 2.5mm wires, but 6mm wires were required to be compliant with manufacturer standards.

Technician replaced the wires on the two pumps, and pump 1 was tested (but not pump 2).

The following day when unloading base oil product, pump 2 started to work in reverse.

97 kg of product was released through the inspection cover.

-

Why did it happen?

Pump 2 had been fitted with two inversed wires and was not standard compliant.

Inversed wires caused the pump to work in the wrong direction, resulting in spillage.

The maintenance test was only performed on pump 1, but not on pump 2.

End-of-work acceptance process was not followed.

-

What did they learn?

All equipment must be fully tested after any maintenance.

Use an end-of-work acceptance process – make it a habit.

Perform test measurement of all three-phase sockets with a phasemeter.

When dealing with spillages:

- clean and wash affected area

- use environmental emergency kits

-

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

Why do you think the maintenance operator did not test all the pumps? Have you ever done something similar? Why?

How do we know everything has been tested (and working correctly) after maintenance?

What would management say and do if this happened on our site? How would that be helpful/not helpful?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

While using oil pumps, employee smelt burning from an electrical control panel.

Inspection found that the panel used 2.5mm wires, but 6mm wires were required to be compliant with manufacturer standards.

Technician replaced the wires on the two pumps, and pump 1 was tested (but not pump 2).

The following day when unloading base oil product, pump 2 started to work in reverse.

97 kg of product was released through the inspection cover.

Why did it happen?

Pump 2 had been fitted with two inversed wires and was not standard compliant.

Inversed wires caused the pump to work in the wrong direction, resulting in spillage.

The maintenance test was only performed on pump 1, but not on pump 2.

End-of-work acceptance process was not followed.

What did they learn?

All equipment must be fully tested after any maintenance.

Use an end-of-work acceptance process – make it a habit.

Perform test measurement of all three-phase sockets with a phasemeter.

When dealing with spillages:

- clean and wash affected area

- use environmental emergency kits

Ask yourself or your crew

What other actions could have been taken?

How can something like this happen here?

Why do you think the maintenance operator did not test all the pumps? Have you ever done something similar? Why?

How do we know everything has been tested (and working correctly) after maintenance?

What would management say and do if this happened on our site? How would that be helpful/not helpful?

A pump was fitted with 2 inversed wires, which caused it to work in reverse when unloading base oil product. 97 kg of product was released through the inspection cover.