-

What happened?

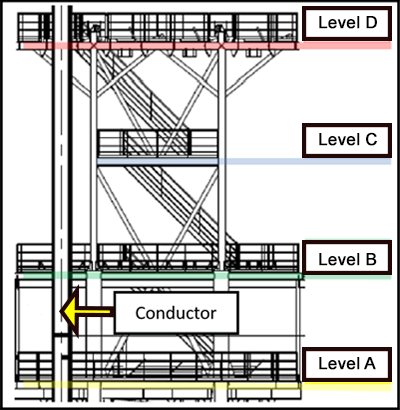

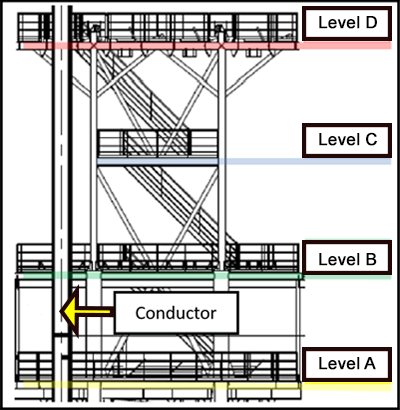

During a decommissioning project, a conductor support frame was used to help with the removal of conductors. Conductors were pulled into position in the conductor support frame by crane.

As per the procedure, wooden wedges were installed to reduce horizontal movements while the conductors were being cut in smaller sections.

After completion of the sectioning cut at level A, the rigging team started to remove the wedges installed at level B, as per original procedure.

Whilst removing the wedges at level B, one of the wedges installed at level D, weighing approximately 13 kg, dropped 6 m (20 ft) to level B striking a rigger’s hard hat and shoulder.

The rigger suffered minor cuts. It was fortunate that his injuries were not more serious.

-

Why did it happen?

To reduce movements from the top of the conductor, additional wedges were installed at level D (top level) - this addition was not part of any procedure.

Procedures had not been updated to include the additional wedges at level D. Management of change was not implemented/followed.

There was a failure of the wedge securing eyes due to vertical movement of the conductors, caused by vessel/platform movement.

It was not identified that removal of the (upper) level D wedges prior to removal of the (lower) level B wedges would have eliminated the dropped object risk.

-

What did they learn?

Any change to a procedure should be subject to management of change.

Procedures should be updated immediately and re-issued to include any changes.

Any changes to procedures should be communicated to all personnel potentially affected by the change.

All persons involved should take part in risk assessments/job safety analysis (JSA) in order to ensure all hazards are identified and eliminated/controlled.

-

Ask yourself or your crew

How can something like this happen here?

Think of a time you deviated from procedure. Why did that make sense at the time?

What should we do if the plan or procedure needs to change?

How can we ensure risk assessment considers all hazards – even if the plan or procedure changes?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a decommissioning project, a conductor support frame was used to help with the removal of conductors. Conductors were pulled into position in the conductor support frame by crane.

As per the procedure, wooden wedges were installed to reduce horizontal movements while the conductors were being cut in smaller sections.

After completion of the sectioning cut at level A, the rigging team started to remove the wedges installed at level B, as per original procedure.

Whilst removing the wedges at level B, one of the wedges installed at level D, weighing approximately 13 kg, dropped 6 m (20 ft) to level B striking a rigger’s hard hat and shoulder.

The rigger suffered minor cuts. It was fortunate that his injuries were not more serious.

Why did it happen?

To reduce movements from the top of the conductor, additional wedges were installed at level D (top level) - this addition was not part of any procedure.

Procedures had not been updated to include the additional wedges at level D. Management of change was not implemented/followed.

There was a failure of the wedge securing eyes due to vertical movement of the conductors, caused by vessel/platform movement.

It was not identified that removal of the (upper) level D wedges prior to removal of the (lower) level B wedges would have eliminated the dropped object risk.

What did they learn?

Any change to a procedure should be subject to management of change.

Procedures should be updated immediately and re-issued to include any changes.

Any changes to procedures should be communicated to all personnel potentially affected by the change.

All persons involved should take part in risk assessments/job safety analysis (JSA) in order to ensure all hazards are identified and eliminated/controlled.

Ask yourself or your crew

How can something like this happen here?

Think of a time you deviated from procedure. Why did that make sense at the time?

What should we do if the plan or procedure needs to change?

How can we ensure risk assessment considers all hazards – even if the plan or procedure changes?

During a decommissioning project, a wooden wedge dropped 6 m onto a rigger. The procedures had not been updated following a change of plan.