-

What happened?

A worker was carrying out maintenance on a vessel’s main engine.

They needed to remove the charge air cooler (weighing 400kg/880lbs).

A chain hoist had been installed on a running beam in the engine room to help with this type of lift.

The chain hoist had a safe working load of 500kg (1100lbs).

The worker was in the process of lifting the item when the electric chain hoist failed.

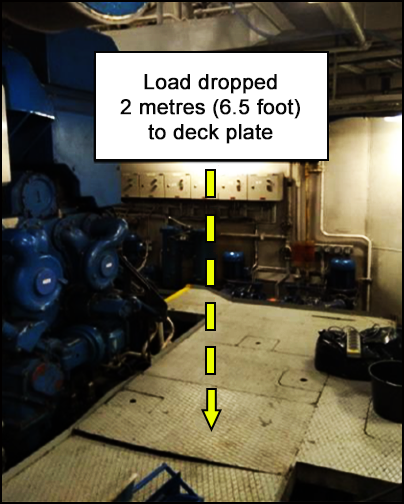

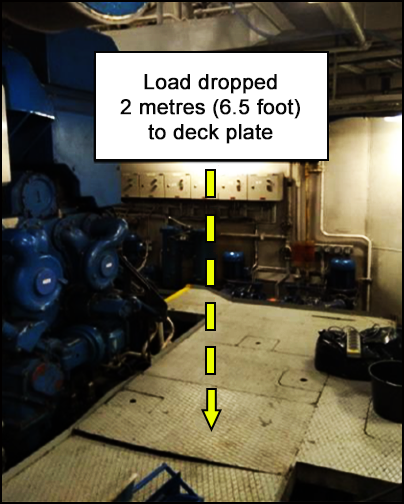

The load dropped 2m (6.5ft) to the engine room deck plating.

Good planning and rigging practice resulted in no workers being in the line of fire.

-

Why did it happen?

Internal corrosion within the infrequently used unit affected the braking mechanisms – they did not function correctly when under load.

The failure meant that the clutch was unable to hold the load, which was lowered uncontrollably.

Inspection regime for the hoist was up to date, but considered inadequate:

- No internal inspection had been completed.

- Visual inspection only could not detect internal corrosion.

- Function test was performed without load.

-

What did they learn?

Powered hoists fitted with overload devices should be set at a working load limit of +10% and checked annually as part of the planned maintenance regime.

Carry out a full inventory of all powered hoists (pneumatic and electric).

- Include both chain and wire hoists.

- Include temporary installed units.

Consider additional maintenance scope for lifting equipment, on top of the planned maintenance.

-

Ask yourself or your crew

Has anything like this ever happened to you or a fellow worker?

What is your maintenance regime for hoists and how often is it carried out?

- Does it include internal inspection?

- Are function tests carried out with/without load? If without load, should we change this?

What checks do you carry out on equipment before you start using it?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was carrying out maintenance on a vessel’s main engine.

They needed to remove the charge air cooler (weighing 400kg/880lbs).

A chain hoist had been installed on a running beam in the engine room to help with this type of lift.

The chain hoist had a safe working load of 500kg (1100lbs).

The worker was in the process of lifting the item when the electric chain hoist failed.

The load dropped 2m (6.5ft) to the engine room deck plating.

Good planning and rigging practice resulted in no workers being in the line of fire.

Why did it happen?

Internal corrosion within the infrequently used unit affected the braking mechanisms – they did not function correctly when under load.

The failure meant that the clutch was unable to hold the load, which was lowered uncontrollably.

Inspection regime for the hoist was up to date, but considered inadequate:

- No internal inspection had been completed.

- Visual inspection only could not detect internal corrosion.

- Function test was performed without load.

What did they learn?

Powered hoists fitted with overload devices should be set at a working load limit of +10% and checked annually as part of the planned maintenance regime.

Carry out a full inventory of all powered hoists (pneumatic and electric).

- Include both chain and wire hoists.

- Include temporary installed units.

Consider additional maintenance scope for lifting equipment, on top of the planned maintenance.

Ask yourself or your crew

Has anything like this ever happened to you or a fellow worker?

What is your maintenance regime for hoists and how often is it carried out?

- Does it include internal inspection?

- Are function tests carried out with/without load? If without load, should we change this?

What checks do you carry out on equipment before you start using it?

A worker was removing a charge air cooler on a vessel. They used the chain hoist installed in the engine room. The chain hoist failed, and the load dropped 2m(6.5ft) to the deck plating. Good planning and rigging practice resulted in no workers being in the line of fire.