-

What happened?

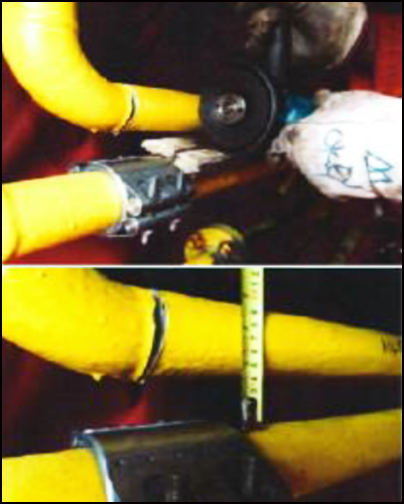

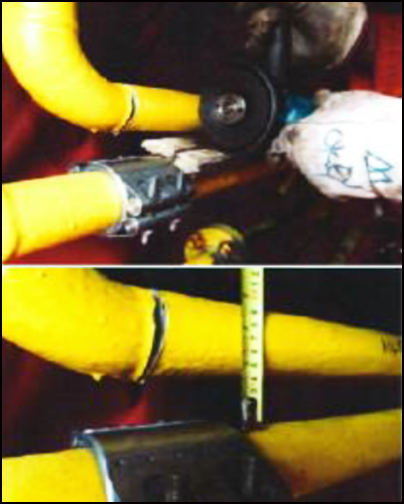

Workers were cutting a 5cm/2-inch nitrogen line.

They identified the risk of cutting an adjacent line and fitted a piece of wood as a protective measure.

The fitter had successfully made 4 cuts on the same nitrogen line at different locations.

During the last cut, due to restricted access, the fitter did not notice the piece of wood had fallen off.

The adjacent diesel line was cut accidentally (5% circumference cut), allowing 10 litres of diesel to leak.

The diesel line was pressurised and supplying a fire water pump at the time (which needed to be available).

-

Why did it happen?

Use of an unsecured protection (piece of wood) for the adjacent line combined with congested access.

The job risk analysis did not consider the possibility to impact an adjacent line.

Use of a generic risk assessment. The risk of cutting the adjacent line was not identified.

Inadequate management of change: the risk was identified on site at job start, but the work was not stopped for reassessment.

-

What did they learn?

Cold cutting is strongly recommended if access is restrictive and does not allow cutting the entire circumference of a pipe.

Before starting the job, check and validate that the physical protection against damage is adequate and can be installed.

Conduct a job risk analysis on site to review and analyse the operating mode/method statements, assess the working environment, and specify the mitigation measures.

Conduct a toolbox talk just before the operation to:

- ensure mitigation measures defined in job risk analysis are applied, enough and efficient.

- analyse the working environment: above, below, nearby the location – is there any other job on-going or planned?

If mitigation measures cannot be applied or are not sustainable, stop the operation, suspend the permit to work and inform management.

-

Ask yourself or your crew

How can something like this happen here?

What could the operators have done differently in this incident?

What can go wrong during today’s task? What hazards have been considered? What have we missed?

What protection do we have in place to protect adjacent equipment? What more can we do?

What else can we learn from this incident?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were cutting a 5cm/2-inch nitrogen line.

They identified the risk of cutting an adjacent line and fitted a piece of wood as a protective measure.

The fitter had successfully made 4 cuts on the same nitrogen line at different locations.

During the last cut, due to restricted access, the fitter did not notice the piece of wood had fallen off.

The adjacent diesel line was cut accidentally (5% circumference cut), allowing 10 litres of diesel to leak.

The diesel line was pressurised and supplying a fire water pump at the time (which needed to be available).

Why did it happen?

Use of an unsecured protection (piece of wood) for the adjacent line combined with congested access.

The job risk analysis did not consider the possibility to impact an adjacent line.

Use of a generic risk assessment. The risk of cutting the adjacent line was not identified.

Inadequate management of change: the risk was identified on site at job start, but the work was not stopped for reassessment.

What did they learn?

Cold cutting is strongly recommended if access is restrictive and does not allow cutting the entire circumference of a pipe.

Before starting the job, check and validate that the physical protection against damage is adequate and can be installed.

Conduct a job risk analysis on site to review and analyse the operating mode/method statements, assess the working environment, and specify the mitigation measures.

Conduct a toolbox talk just before the operation to:

- ensure mitigation measures defined in job risk analysis are applied, enough and efficient.

- analyse the working environment: above, below, nearby the location – is there any other job on-going or planned?

If mitigation measures cannot be applied or are not sustainable, stop the operation, suspend the permit to work and inform management.

Ask yourself or your crew

How can something like this happen here?

What could the operators have done differently in this incident?

What can go wrong during today’s task? What hazards have been considered? What have we missed?

What protection do we have in place to protect adjacent equipment? What more can we do?

What else can we learn from this incident?

Workers were cutting a 5cm/2-inch nitrogen line. They identified the risk of cutting an adjacent line and fitted a piece of wood as a protective measure. During the last cut, an adjacent diesel line was cut accidentality allowing 10 litres of diesel to leak.