-

What happened?

A fast rescue craft (FRC) was being retrieved (lifted) using a winch.

Whenever the craft started to sway the winch button was disengaged and then re-engaged once the swaying stopped. This happened several times.

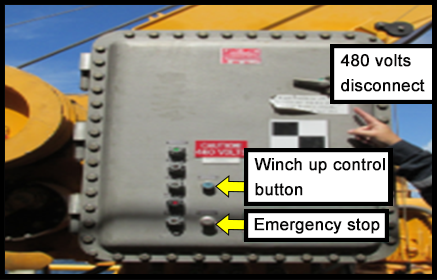

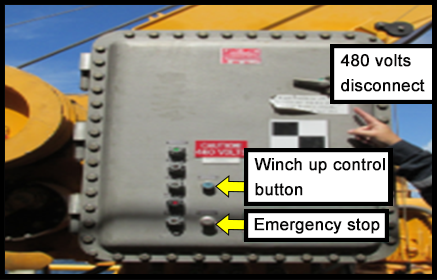

When the craft reached the docking point the button was disengaged, however the winch continued to lift the craft, even after the emergency stop was pulled and ‘anti-two block’ (limit switch) was reached.

The operator opened the 480 volts breaker on the control panel, stopping the winch before the craft was pulled into the davit.

-

Why did it happen?

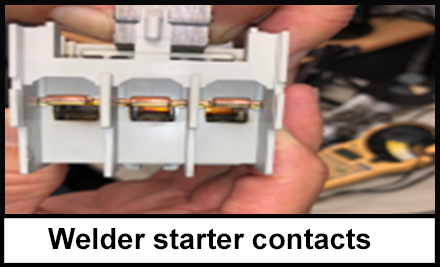

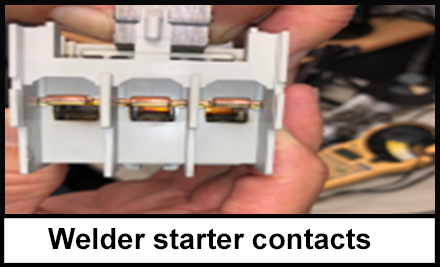

Power was not cut from the winch because the start/stop button, emergency stop and anti-two block limit switch starter contacts had welded together.

-

What did they learn?

Cycling the winch start/stop push button more than once per minute can cause the starter contacts to weld together and not remove power from the winch.

The winch start/stop push button, the emergency stop, and the anti-two block limit switch only break the 120V control circuit to the winch motor starter. If the starter contacts happen to weld together these safeguards will not stop the winch motor.

-

Ask yourself or your crew

Were you aware this could happen?

If we had such a failure, and someone was seriously hurt, what would be our key steps in response?

What actions could have been taken to prevent this?

What changes should we make to procedures or processes to prevent this happening here?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A fast rescue craft (FRC) was being retrieved (lifted) using a winch.

Whenever the craft started to sway the winch button was disengaged and then re-engaged once the swaying stopped. This happened several times.

When the craft reached the docking point the button was disengaged, however the winch continued to lift the craft, even after the emergency stop was pulled and ‘anti-two block’ (limit switch) was reached.

The operator opened the 480 volts breaker on the control panel, stopping the winch before the craft was pulled into the davit.

Why did it happen?

Power was not cut from the winch because the start/stop button, emergency stop and anti-two block limit switch starter contacts had welded together.

What did they learn?

Cycling the winch start/stop push button more than once per minute can cause the starter contacts to weld together and not remove power from the winch.

The winch start/stop push button, the emergency stop, and the anti-two block limit switch only break the 120V control circuit to the winch motor starter. If the starter contacts happen to weld together these safeguards will not stop the winch motor.

Ask yourself or your crew

Were you aware this could happen?

If we had such a failure, and someone was seriously hurt, what would be our key steps in response?

What actions could have been taken to prevent this?

What changes should we make to procedures or processes to prevent this happening here?

A rescue craft was being retrieved using a winch. When the craft reached the docking point the control button was disengaged, however the winch continued to lift the craft as it was still powered.