-

What happened?

Two riser protection guards were being transferred to a crane barge. The planned storage location was inappropriate, so a new location was found.

To safely store the guards vertically at the new location, 2 guideposts (4.8m/16ft long, 1.1 tons) needed to be installed.

The first guidepost was lifted using the whip line hook of the deck crawler crane and two 5.5m/18ft web slings.

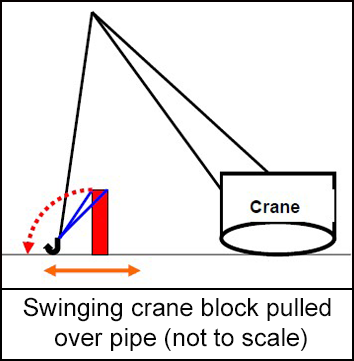

The post was landed on the deck. A single tack weld to a base plate was made with some difficulty, as the sea swell was causing the crane block to swing.

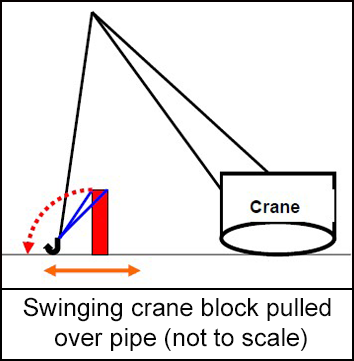

The foreman asked the crane driver to lower the block to the deck to stop it swinging.

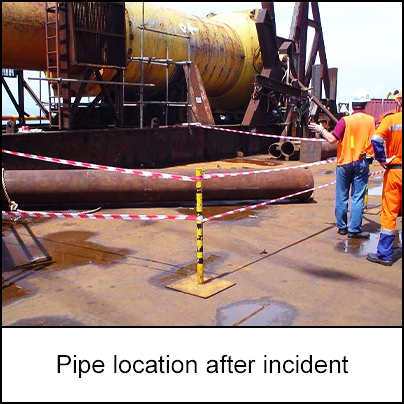

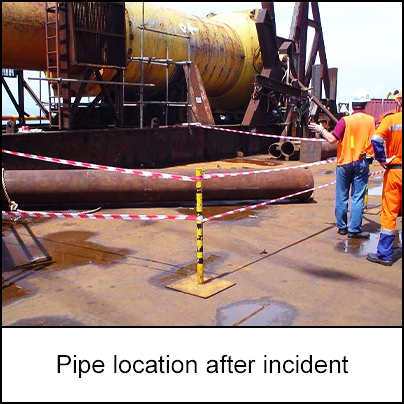

As the block was lowered, it caused the slings (nearly the same length as the guidepost) to come under tension, pulling the post over.

The post landed on the welder, who had his back to the work. He was killed instantly.

-

Why did it happen?

Lack of safety awareness: the job was not considered dangerous by the crew:

- Turning backs on the work in progress.

- No exclusion zone established.

- Supervisors not ensuring safety procedures were being followed.

Welding and lifting tasks considered ‘routine’. Carried out with no instructions/procedures, job safety analysis, toolbox talk, or permit to work.

Management of change: change of location and method of storage not properly planned and documented:

- Support for the guidepost to rest free standing on deck not planned or provided.

- Crawler crane had no tugger line and was not adapted for the work.

- Web-sling length: shorter slings wouldn’t have swayed so much, longer ones wouldn’t have pulled the guidepost over.

-

What did they learn?

For pipes installed on decks:

- A small stub should be welded in place first. The pipe can then be slid over this.

- Alternatively, short angled supports could be welded onto the pipe first to provide free-standing ability.

Be aware of the risks of sea swell – and how to react to them.

Adequate risk assessments should be conducted and safety measures should be in place before the work starts.

Everyone should be made aware of all the risks involved in ‘routine’ tasks. We all have the responsibility to stop work if it is unsafe.

Crews should be trained in how to conduct job safety analysis and toolbox talks.

Procedures to control management of change should be in place and applied.

Equipment should be adapted to the task. On floating vessels, ensure all crane blocks have tugger lines fitted, or that procedures are in place to stop swinging (use of short slings and small hook extension with tugger ropes where possible).

-

Ask yourself or your crew

How can something like this happen here?

What could the workers have done differently?

What tasks do we consider to be ‘routine’? What are the risks involved in these tasks?

What is the plan for today’s lifting/welding operation?

What controls can we put in place to stop something like this from happening here?

When are you authorised to stop work?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two riser protection guards were being transferred to a crane barge. The planned storage location was inappropriate, so a new location was found.

To safely store the guards vertically at the new location, 2 guideposts (4.8m/16ft long, 1.1 tons) needed to be installed.

The first guidepost was lifted using the whip line hook of the deck crawler crane and two 5.5m/18ft web slings.

The post was landed on the deck. A single tack weld to a base plate was made with some difficulty, as the sea swell was causing the crane block to swing.

The foreman asked the crane driver to lower the block to the deck to stop it swinging.

As the block was lowered, it caused the slings (nearly the same length as the guidepost) to come under tension, pulling the post over.

The post landed on the welder, who had his back to the work. He was killed instantly.

Why did it happen?

Lack of safety awareness: the job was not considered dangerous by the crew:

- Turning backs on the work in progress.

- No exclusion zone established.

- Supervisors not ensuring safety procedures were being followed.

Welding and lifting tasks considered ‘routine’. Carried out with no instructions/procedures, job safety analysis, toolbox talk, or permit to work.

Management of change: change of location and method of storage not properly planned and documented:

- Support for the guidepost to rest free standing on deck not planned or provided.

- Crawler crane had no tugger line and was not adapted for the work.

- Web-sling length: shorter slings wouldn’t have swayed so much, longer ones wouldn’t have pulled the guidepost over.

What did they learn?

For pipes installed on decks:

- A small stub should be welded in place first. The pipe can then be slid over this.

- Alternatively, short angled supports could be welded onto the pipe first to provide free-standing ability.

Be aware of the risks of sea swell – and how to react to them.

Adequate risk assessments should be conducted and safety measures should be in place before the work starts.

Everyone should be made aware of all the risks involved in ‘routine’ tasks. We all have the responsibility to stop work if it is unsafe.

Crews should be trained in how to conduct job safety analysis and toolbox talks.

Procedures to control management of change should be in place and applied.

Equipment should be adapted to the task. On floating vessels, ensure all crane blocks have tugger lines fitted, or that procedures are in place to stop swinging (use of short slings and small hook extension with tugger ropes where possible).

Ask yourself or your crew

How can something like this happen here?

What could the workers have done differently?

What tasks do we consider to be ‘routine’? What are the risks involved in these tasks?

What is the plan for today’s lifting/welding operation?

What controls can we put in place to stop something like this from happening here?

When are you authorised to stop work?

A welder was killed instantly when a 1.1 tons post was dropped. The welding and lifting tasks were considered ‘routine’ and carried out without instructions/procedures, job safety analysis, tool box talk, or permit to work.