-

What happened?

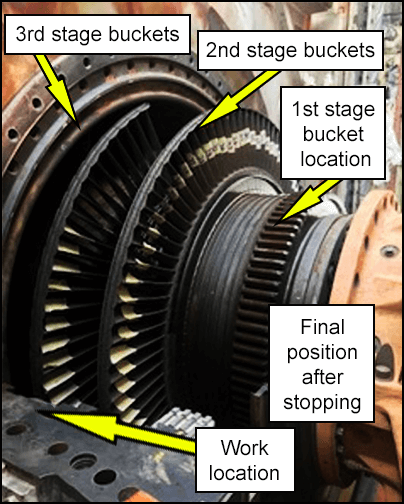

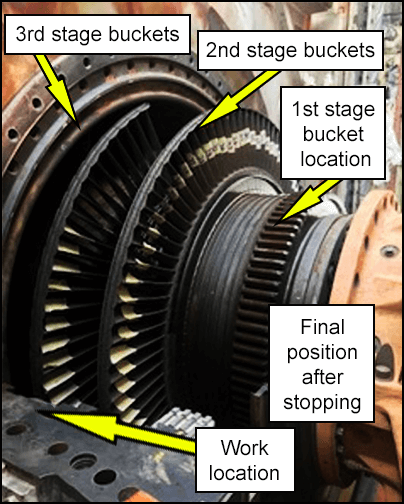

A planned turbine hot gas path inspection (HGPI) was being conducted.

The rotor assembly was exposed, and the shaft was rotated to replace hot gas components.

To replace the rotor bucket, a technician was positioned in the work area, and his supervisor was at the turbine ratchet motor, manually controlling the rotation of the shaft using a jog button.

Typically, all work crew are cleared from the area when the shaft is rotated.

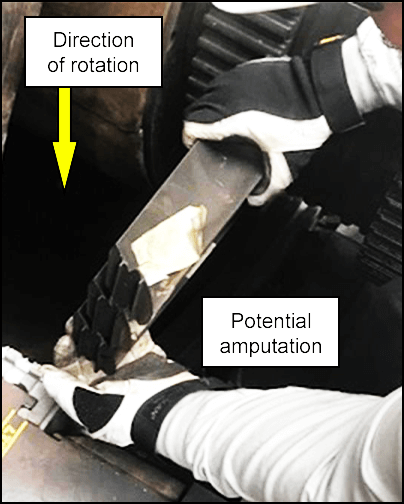

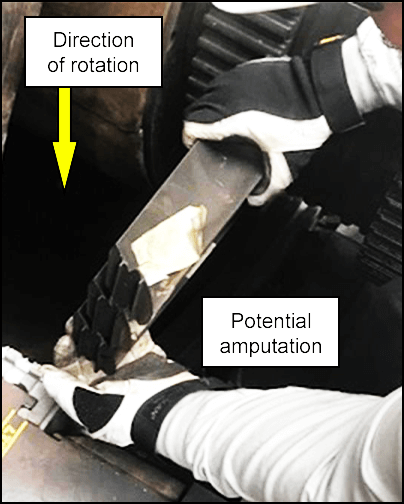

About half-way through bucket removal the technician stopped and stepped back. At that moment, the shaft unexpectedly rotated.

If the technician had maintained his position, his hand could have been amputated by the shaft.

-

Why did it happen?

The shaft moved because a separate function test on a different component in the turbine control system was being carried out simultaneously (unknown to the team). This continuously engaged the ratchet motor and turned the shaft.

- Inter-related activities were not identified in the daily work coordination meeting.

The ratchet motor was not positively isolated, and zero energy had not been demonstrated.

- The team were unaware of the requirement for positive isolation.

The manual jog button was incorrectly assumed as an effective control.

The impact of logic changes during crude firing project were not fully recognised.

-

What did they learn?

Confirm that workers are aware of the procedures for their tasks and follow them.

Verify positive isolation and demonstrate zero energy before starting critical work.

Make sure there is good communication between all teams on site.

Recognise and manage the impact from simultaneous activities that can create stored energy.

-

Ask yourself or your crew

How can something like this happen here?

How do you know if any activities that might impact your work are being carried out simultaneously?

How do you demonstrate zero energy and positive on your equipment?

What other hazards should you look for during gas turbines inspections?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A planned turbine hot gas path inspection (HGPI) was being conducted.

The rotor assembly was exposed, and the shaft was rotated to replace hot gas components.

To replace the rotor bucket, a technician was positioned in the work area, and his supervisor was at the turbine ratchet motor, manually controlling the rotation of the shaft using a jog button.

Typically, all work crew are cleared from the area when the shaft is rotated.

About half-way through bucket removal the technician stopped and stepped back. At that moment, the shaft unexpectedly rotated.

If the technician had maintained his position, his hand could have been amputated by the shaft.

Why did it happen?

The shaft moved because a separate function test on a different component in the turbine control system was being carried out simultaneously (unknown to the team). This continuously engaged the ratchet motor and turned the shaft.

- Inter-related activities were not identified in the daily work coordination meeting.

The ratchet motor was not positively isolated, and zero energy had not been demonstrated.

- The team were unaware of the requirement for positive isolation.

The manual jog button was incorrectly assumed as an effective control.

The impact of logic changes during crude firing project were not fully recognised.

What did they learn?

Confirm that workers are aware of the procedures for their tasks and follow them.

Verify positive isolation and demonstrate zero energy before starting critical work.

Make sure there is good communication between all teams on site.

Recognise and manage the impact from simultaneous activities that can create stored energy.

Ask yourself or your crew

How can something like this happen here?

How do you know if any activities that might impact your work are being carried out simultaneously?

How do you demonstrate zero energy and positive on your equipment?

What other hazards should you look for during gas turbines inspections?

A planned turbine hot gas path inspection (HGPI) was being carried out. About half-way through bucket removal the technician stopped and stepped back. At that moment, the shaft unexpectedly rotated. If the technician had maintained his position, his hand could have been amputated by the shaft.