-

What happened?

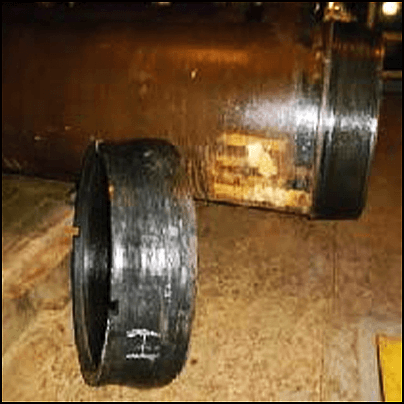

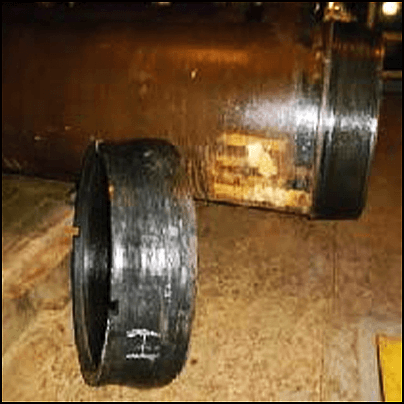

A 30in (76cm) conductor pipe was being hoisted by a starboard crane.

During the operation, the protection collar on the pipe fell 1ft (30cm) onto the deck.

Crane operator reported the near miss and potential dropped object.

Crew was instructed to check the remaining protection collars to ensure they are adequately secured.

-

Why did it happen?

Protection collar was not torqued tight enough on the pipe end.

Collars were only visually inspected to make sure they were covering the pipe ends.

No mandatory checks for physical tightening.

Factors that can affect protectors during loading/unloading/transport:

- Protectors may not be torqued tight enough.

- Protectors are made of rubber and when knocked, they slacken easily.

- Protectors could slacken in transit due to vibrations or knocked by other objects, hit by water etc).

-

What did they learn?

Ensure protection collars are secured before starting to load the pipes.

Gantry team should visually inspect pipe protectors that are accessible and visible/practical to check.

- Any slackness observed should be reported to the relevant authority.

Incident details should be passed to the vendors, requesting for extra vigilance on securing protectors on pipes.

-

Ask yourself or your crew

Has anything like this ever happened on your site/vessel?

How do we check that all protection collars are in place and protect the pipes effectively before starting the job?

- If you observe anything abnormal, who do you report it to?

What other checks do we perform before lifting pipes/other loads?

What other risks are there with lifting and hoisting activities on vessels?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A 30in (76cm) conductor pipe was being hoisted by a starboard crane.

During the operation, the protection collar on the pipe fell 1ft (30cm) onto the deck.

Crane operator reported the near miss and potential dropped object.

Crew was instructed to check the remaining protection collars to ensure they are adequately secured.

Why did it happen?

Protection collar was not torqued tight enough on the pipe end.

Collars were only visually inspected to make sure they were covering the pipe ends.

No mandatory checks for physical tightening.

Factors that can affect protectors during loading/unloading/transport:

- Protectors may not be torqued tight enough.

- Protectors are made of rubber and when knocked, they slacken easily.

- Protectors could slacken in transit due to vibrations or knocked by other objects, hit by water etc).

What did they learn?

Ensure protection collars are secured before starting to load the pipes.

Gantry team should visually inspect pipe protectors that are accessible and visible/practical to check.

- Any slackness observed should be reported to the relevant authority.

Incident details should be passed to the vendors, requesting for extra vigilance on securing protectors on pipes.

Ask yourself or your crew

Has anything like this ever happened on your site/vessel?

How do we check that all protection collars are in place and protect the pipes effectively before starting the job?

- If you observe anything abnormal, who do you report it to?

What other checks do we perform before lifting pipes/other loads?

What other risks are there with lifting and hoisting activities on vessels?

A conductor pipe was being hoisted by a starboard crane. While it was being moved, the protection collar fell off and hit the deck of the vessel.