-

What happened?

A fuel tanker truck slid off the road while on route to an aviation depot.

The tank hit the right rear of the truck cab and fell onto the road – landing on the opposite side.

An oncoming vehicle crashed into the tank.

Damage was caused to the vehicle, road and the curb wall.

Emergency services were called. A sand dyke was created to contain the minor fuel spill and adsorbent pads used for clean-up.

-

Why did it happen?

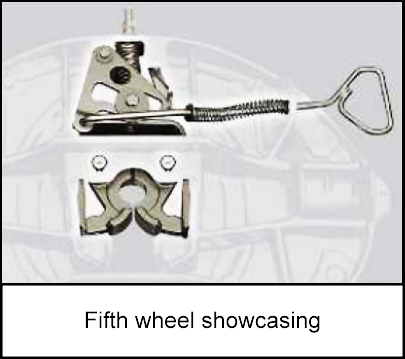

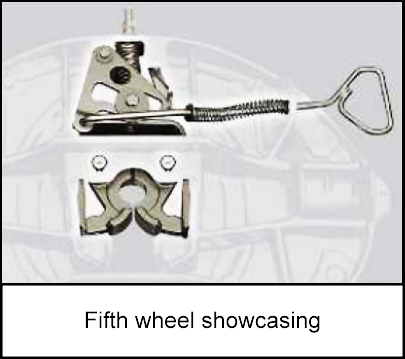

Equipment failure: the compression spring in the yoke shaft was too loose causing the adjustment nut to be stiff.

The coupling between the fifth wheel and bull pin was done incorrectly due to inadequate training/instructions.

Adjustment nut was not flush against the front plate.

Inadequate maintenance/inspection of the fifth wheel.

-

What did they learn?

Carry out a safety stand down – all haulers should check their fifth wheel and bull pin are as per manual and specifications.

Ensure all haulers update their maintenance plan including fifth wheel and bull pin maintenance.

Organise drivers’ training session focusing on accident, causes, and action plan including maintenance and three visual inspection:

- Inspection of the lock jaws to ensure they are completely closed around the bull pin.

- Check if the release handle/loop is fully retracted into the lock position.

- Visually verify that the lock indicator nut is flush against the top plate.

Ensure mechanics and drivers are fully trained on the equipment – especially where is high potential with severe consequences.

-

Ask yourself or your crew

Have you ever been in a similar road accident? What was the cause?

Are you fully trained to operate the equipment you need to use today?

Did you do the three visual inspection today? What are the steps?

How can you ensure that the equipment maintenance plan is up to date?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A fuel tanker truck slid off the road while on route to an aviation depot.

The tank hit the right rear of the truck cab and fell onto the road – landing on the opposite side.

An oncoming vehicle crashed into the tank.

Damage was caused to the vehicle, road and the curb wall.

Emergency services were called. A sand dyke was created to contain the minor fuel spill and adsorbent pads used for clean-up.

Why did it happen?

Equipment failure: the compression spring in the yoke shaft was too loose causing the adjustment nut to be stiff.

The coupling between the fifth wheel and bull pin was done incorrectly due to inadequate training/instructions.

Adjustment nut was not flush against the front plate.

Inadequate maintenance/inspection of the fifth wheel.

What did they learn?

Carry out a safety stand down – all haulers should check their fifth wheel and bull pin are as per manual and specifications.

Ensure all haulers update their maintenance plan including fifth wheel and bull pin maintenance.

Organise drivers’ training session focusing on accident, causes, and action plan including maintenance and three visual inspection:

- Inspection of the lock jaws to ensure they are completely closed around the bull pin.

- Check if the release handle/loop is fully retracted into the lock position.

- Visually verify that the lock indicator nut is flush against the top plate.

Ensure mechanics and drivers are fully trained on the equipment – especially where is high potential with severe consequences.

Ask yourself or your crew

Have you ever been in a similar road accident? What was the cause?

Are you fully trained to operate the equipment you need to use today?

Did you do the three visual inspection today? What are the steps?

How can you ensure that the equipment maintenance plan is up to date?

A fuel tanker truck slid off the road while on route to an aviation depot. The tank hit the back of the truck cab and fell onto the road – landing on the opposite side.