-

What happened?

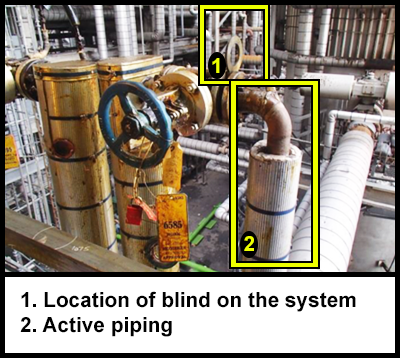

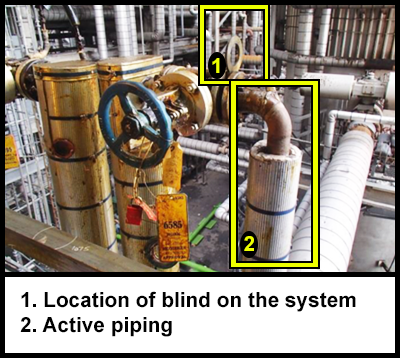

Workers were rolling blinds open on the process side of product pumps so they could be drained.

A worker loosened a flange on the active side of the isolation valve causing release of heavy coker gas oil.

-

Why did it happen?

The flange had been incorrectly installed during a previous project, and was on the active side of an isolation valve and should not have been opened.

This flange was still included in the isolation procedure.

The workers, permit and jobsite visit did not identify that the flange had been incorrectly installed.

-

What did they learn?

Update piping and instrumentation diagrams and procedures so these are accurate. Undocumented changes can be missed.

Confirm piping and instrumentation diagrams are accurate when planning the job.

-

Ask yourself or your crew

How can something like this happen here?

What other actions could have been taken?

Before starting work, how do we know that piping and instrumentation diagrams are accurate?

What is the process for updating procedures?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were rolling blinds open on the process side of product pumps so they could be drained.

A worker loosened a flange on the active side of the isolation valve causing release of heavy coker gas oil.

Why did it happen?

The flange had been incorrectly installed during a previous project, and was on the active side of an isolation valve and should not have been opened.

This flange was still included in the isolation procedure.

The workers, permit and jobsite visit did not identify that the flange had been incorrectly installed.

What did they learn?

Update piping and instrumentation diagrams and procedures so these are accurate. Undocumented changes can be missed.

Confirm piping and instrumentation diagrams are accurate when planning the job.

Ask yourself or your crew

How can something like this happen here?

What other actions could have been taken?

Before starting work, how do we know that piping and instrumentation diagrams are accurate?

What is the process for updating procedures?

Workers were rolling blinds open on the process side of product pumps so they could be drained. A worker loosened a flange on the active side of the isolation valve causing release of heavy coker gas oil.