-

What happened?

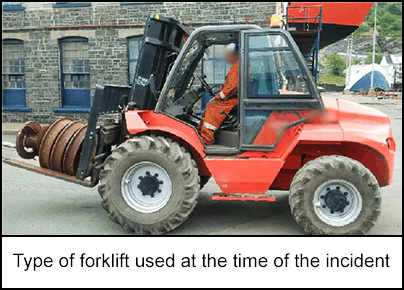

A worker was crossing the shipyard when they were struck by the forklift on their leg.

The blow resulted in them spinning and falling across the forks, striking their right shoulder and hip and dislodging their hard hat and safety glasses.

The operator stopped the machine as the person was falling across the forks and exited the forklift to see if there were any injuries.

The injured worker appeared fine and returned to their work area.

However, the shoulder and hip pain did not ease off, and although precautionary hospital tests showed no broken bones or internal injuries, the worker was placed on restricted work duties.

The incident was captured on the shipyard’s security camera.

-

Why did it happen?

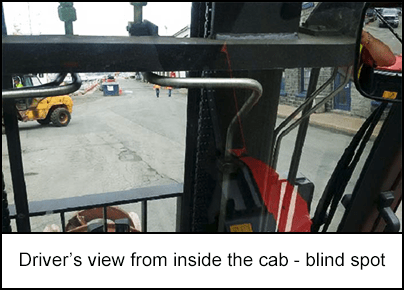

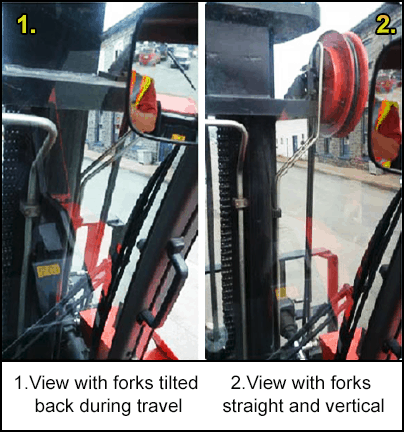

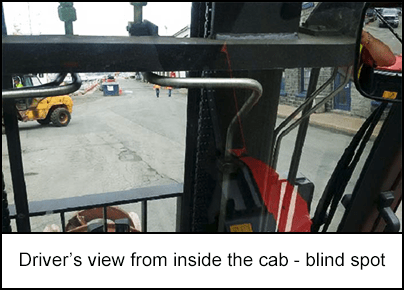

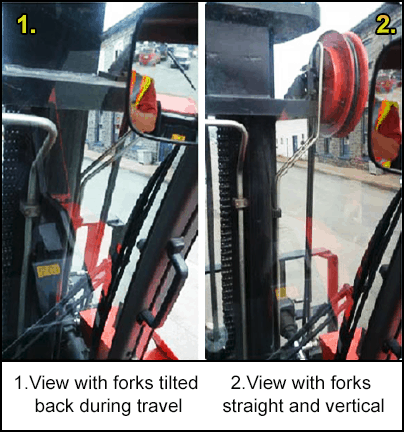

Forklift’s cab design did not allow for a clear wide-angle view from the operator’s position – the injured person was in the forklift driver’s blind spot.

The driver was aware that the forklift had blind spots after operating it for the first time but failed to monitor these.

The forklift operator made an unexpected adjustment in their driving angle due to a truck parked next to a building.

Inadequate identification of hazards in the shipyard:

- There were no dedicated walkways around the shipyard – workers were able to go anywhere they wanted without restrictions.

- However, this hazard was identified in the workshop/machine shops and walkways have been painted.

No traffic management for mobile equipment. Workers could transit the yard at any angle in any direction, leaving the equipment operator vulnerable to an incident.

The injured worker did not see the forklift until it hit them – they failed to be aware of mobile machinery in the shipyard.

Both the forklift operator and worker were complacent about the risks.

-

What did they learn?

Ensure that all workers are wearing appropriate personal protective equipment (PPE) when walking around the shipyard.

Try to keep the shipyard as tidy and clear of obstacles as possible.

Ensure that workers are aware of the risks of traversing the shipyard, and do not become complacent.

Limit the speed of the yard forklifts and other machinery to a maximum of 15km/hr.

Release a bulletin highlighting the incident and invite suggestions for improvement from their workforce.

Review relevant standards for lifting trucks and adopt any recommendations.

-

Ask yourself or your crew

What can you do about known issues (such as blind spots when driving) to reduce the risks of incidents occurring?

How do you stop yourself becoming complacent about risks around your site?

What can you do if you see equipment being operated unsafely (too fast, operators ignoring signage etc.)?

What can you do to make your work yards safer (e.g. if there aren’t designated walking routes, traffic management system for mobile equipment or any other site-specific issues)?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was crossing the shipyard when they were struck by the forklift on their leg.

The blow resulted in them spinning and falling across the forks, striking their right shoulder and hip and dislodging their hard hat and safety glasses.

The operator stopped the machine as the person was falling across the forks and exited the forklift to see if there were any injuries.

The injured worker appeared fine and returned to their work area.

However, the shoulder and hip pain did not ease off, and although precautionary hospital tests showed no broken bones or internal injuries, the worker was placed on restricted work duties.

The incident was captured on the shipyard’s security camera.

Why did it happen?

Forklift’s cab design did not allow for a clear wide-angle view from the operator’s position – the injured person was in the forklift driver’s blind spot.

The driver was aware that the forklift had blind spots after operating it for the first time but failed to monitor these.

The forklift operator made an unexpected adjustment in their driving angle due to a truck parked next to a building.

Inadequate identification of hazards in the shipyard:

- There were no dedicated walkways around the shipyard – workers were able to go anywhere they wanted without restrictions.

- However, this hazard was identified in the workshop/machine shops and walkways have been painted.

No traffic management for mobile equipment. Workers could transit the yard at any angle in any direction, leaving the equipment operator vulnerable to an incident.

The injured worker did not see the forklift until it hit them – they failed to be aware of mobile machinery in the shipyard.

Both the forklift operator and worker were complacent about the risks.

What did they learn?

Ensure that all workers are wearing appropriate personal protective equipment (PPE) when walking around the shipyard.

Try to keep the shipyard as tidy and clear of obstacles as possible.

Ensure that workers are aware of the risks of traversing the shipyard, and do not become complacent.

Limit the speed of the yard forklifts and other machinery to a maximum of 15km/hr.

Release a bulletin highlighting the incident and invite suggestions for improvement from their workforce.

Review relevant standards for lifting trucks and adopt any recommendations.

Ask yourself or your crew

What can you do about known issues (such as blind spots when driving) to reduce the risks of incidents occurring?

How do you stop yourself becoming complacent about risks around your site?

What can you do if you see equipment being operated unsafely (too fast, operators ignoring signage etc.)?

What can you do to make your work yards safer (e.g. if there aren’t designated walking routes, traffic management system for mobile equipment or any other site-specific issues)?

A worker was crossing the shipyard when they were struck by the forklift on their leg. They span and fell across the forks, striking their right shoulder and hip and dislodging their hard hat and safety glasses.