-

What happened?

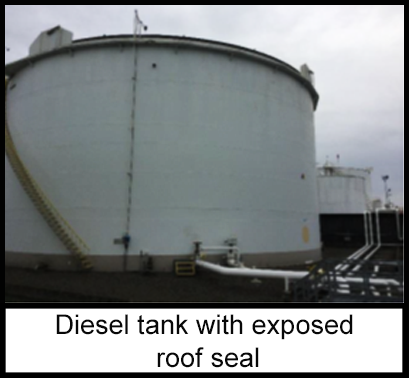

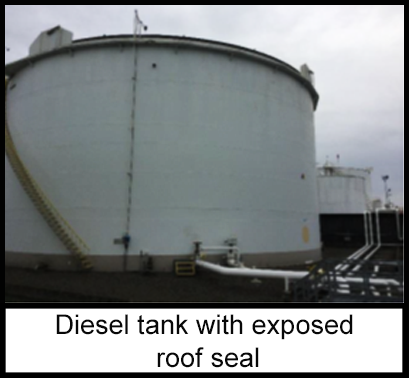

During a pipeline delivery, an operator noticed that the secondary seal on the external floating roof of a diesel tank was exposed above the tank shell height.

The high-level alarm had not activated.

The pipeline delivery was immediately stopped and the tank was isolated.

Near miss: tank overflow could have resulted in product release, fire and explosion.

-

Why did it happen?

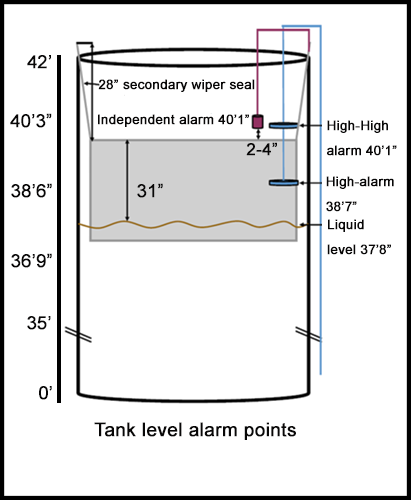

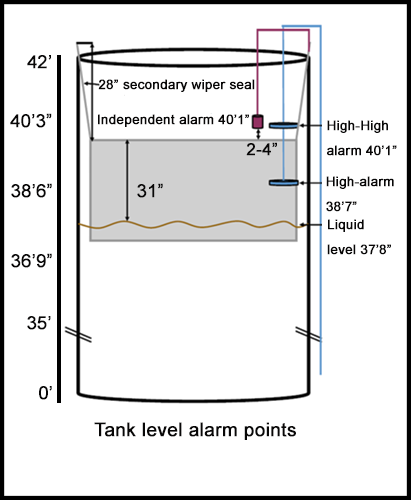

Level alarms had recently been re-calculated, but the thickness of the external floating roof and seals were not accounted for.

The new normal fill level was set 3 feet above the old normal fill level .

The tank level did not reach the new alarm set point, so the alarm did not activate.

-

What did they learn?

Accurate calculation of level alarm settings is critical to operation integrity.

Compare new vs. old settings.

Significant changes should be carefully reviewed and managed with a robust process.

Do not let other priorities stand in the way of reviewing critical process changes.

-

Ask yourself or your crew

How can something like this happen here?

What other actions could have been taken?

What could have been the outcome of this incident?

How do we know that high level alarms are working?

Do we have any standing/disabled alarms? What should we do about them?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a pipeline delivery, an operator noticed that the secondary seal on the external floating roof of a diesel tank was exposed above the tank shell height.

The high-level alarm had not activated.

The pipeline delivery was immediately stopped and the tank was isolated.

Near miss: tank overflow could have resulted in product release, fire and explosion.

Why did it happen?

Level alarms had recently been re-calculated, but the thickness of the external floating roof and seals were not accounted for.

The new normal fill level was set 3 feet above the old normal fill level .

The tank level did not reach the new alarm set point, so the alarm did not activate.

What did they learn?

Accurate calculation of level alarm settings is critical to operation integrity.

Compare new vs. old settings.

Significant changes should be carefully reviewed and managed with a robust process.

Do not let other priorities stand in the way of reviewing critical process changes.

Ask yourself or your crew

How can something like this happen here?

What other actions could have been taken?

What could have been the outcome of this incident?

How do we know that high level alarms are working?

Do we have any standing/disabled alarms? What should we do about them?

During a pipeline delivery, an operator noticed that the secondary seal on the external floating roof of a diesel tank was exposed above the tank shell height. The high-level alarm had not activated.