-

What happened?

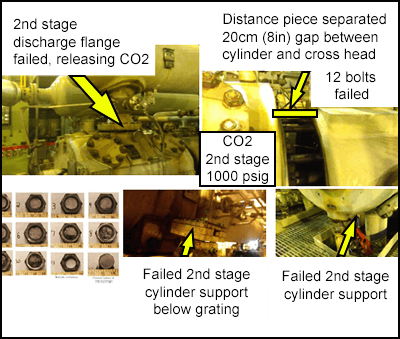

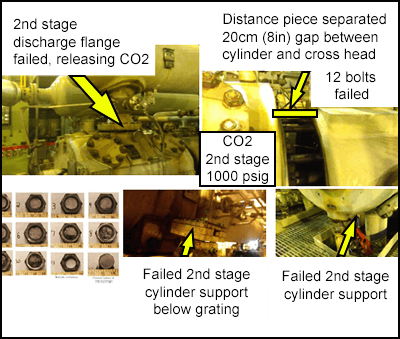

An alarm sounded in a recycle compressor and an area operator was notified.

The area operator was approaching the building when they heard a loud boom.

The CO2 gas alarms sounded, and vapour was seen coming out of the building.

The compressor shut down automatically when the CO2 alarms went off (detected at a maximum of 20,000 ppm).

No H2S was detected during the incident.

-

Why did it happen?

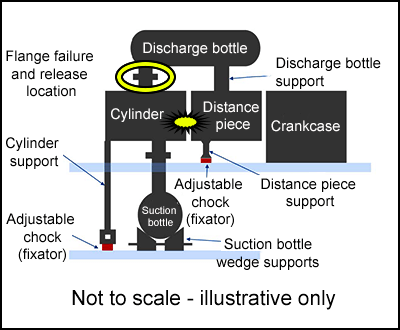

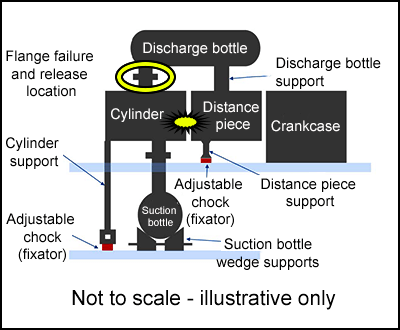

Testing confirmed that studs in many areas of the machinery had failed (at flanges, cylinder supports etc.) through a combination of fatigue and overload failure.

The bolt fatigue was likely to be caused by misalignment of the cylinders, or inadequate torque of the studs.

-

What did they learn?

Confirm that all cylinders are fit for purpose to be able to distance piece studs and supports (see image).

Update procedures for cylinder alignment, surveillance, and maintenance.

Consider the risks of equipment failure in process buildings.

Review technological options (e.g. machine monitoring) for higher risk activities.

Maintain records of adjustments made during previous maintenance activities for accountability and audit purposes (trending and identifying issues).

-

Ask yourself or your crew

How can something like this happen here?

Do we keep a record of adjustments made to recycle compressors (or other equipment) during maintenance?

What could the need for frequent adjustments to equipment tell us about its condition?

How do we know that this won’t happen to our recycle compressor?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

An alarm sounded in a recycle compressor and an area operator was notified.

The area operator was approaching the building when they heard a loud boom.

The CO2 gas alarms sounded, and vapour was seen coming out of the building.

The compressor shut down automatically when the CO2 alarms went off (detected at a maximum of 20,000 ppm).

No H2S was detected during the incident.

Why did it happen?

Testing confirmed that studs in many areas of the machinery had failed (at flanges, cylinder supports etc.) through a combination of fatigue and overload failure.

The bolt fatigue was likely to be caused by misalignment of the cylinders, or inadequate torque of the studs.

What did they learn?

Confirm that all cylinders are fit for purpose to be able to distance piece studs and supports (see image).

Update procedures for cylinder alignment, surveillance, and maintenance.

Consider the risks of equipment failure in process buildings.

Review technological options (e.g. machine monitoring) for higher risk activities.

Maintain records of adjustments made during previous maintenance activities for accountability and audit purposes (trending and identifying issues).

Ask yourself or your crew

How can something like this happen here?

Do we keep a record of adjustments made to recycle compressors (or other equipment) during maintenance?

What could the need for frequent adjustments to equipment tell us about its condition?

How do we know that this won’t happen to our recycle compressor?

An alarm sounded in a recycle compressor. Studs and bolts in the machinery failed, causing a CO2 explosion.