-

What happened?

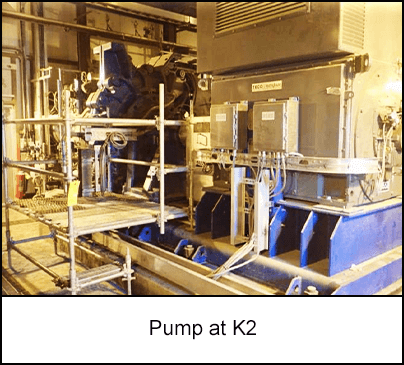

A work crew was changing packing on two pumps in the K2 plant.

They confirmed energy isolation and zero energy on the pumps with K2 operations.

They left K2 plant to retrieve tools from the maintenance shop.

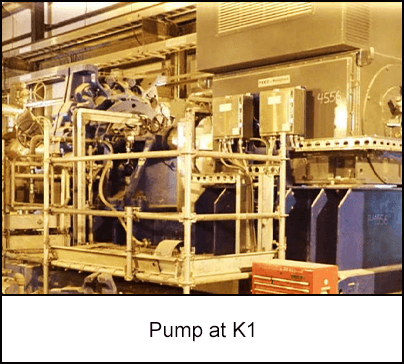

Instead of returning to K2 plant to start work on the pumps, they mistakenly went to K1 plant.

The crew broke containment on two pumps that were on ‘hot standby’ in K1.

-

Why did it happen?

K1 and K2 plant layouts, buildings and equipment were very similar.

The permit holder and area operator did not clarify ‘first break’ for breaking containment on the pumps.

The job safety analysis (JSA) and safe work practice (SWP) checklist were marked as complete without confirming the controls were in place.

The permit holder and work crew broke containment, and removed the pump packing without the area operator present.

-

What did they learn?

Verify you are in the correct plant by confirming the following plant identifiers:

- Signage at the entrance to each plant area e.g. K1 process, K1 utilities etc.

- Signage on the plant buildings and entrances e.g. K1 process pump.

- Verify the full equipment tag number (K1 equipment tag numbers begin with 1500 and K2 with 2500).

Follow work management standards for breaking containment:

- Confirm equipment location for ‘first break’ with the AO.

- Verify JSA and SWP checklist controls are in place before initialling as complete.

- The AO should be present for ‘first break’.

-

Ask yourself or your crew

Identify equipment that looks similar on your worksite. How do you check you are working on the equipment you are meant to be working on?

What controls are in place to stop this happening to you or your colleagues?

What improvements could you make to any processes you follow?

Have you ever witnessed your colleagues working on plant when they should be waiting for supervision? What did you do?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A work crew was changing packing on two pumps in the K2 plant.

They confirmed energy isolation and zero energy on the pumps with K2 operations.

They left K2 plant to retrieve tools from the maintenance shop.

Instead of returning to K2 plant to start work on the pumps, they mistakenly went to K1 plant.

The crew broke containment on two pumps that were on ‘hot standby’ in K1.

Why did it happen?

K1 and K2 plant layouts, buildings and equipment were very similar.

The permit holder and area operator did not clarify ‘first break’ for breaking containment on the pumps.

The job safety analysis (JSA) and safe work practice (SWP) checklist were marked as complete without confirming the controls were in place.

The permit holder and work crew broke containment, and removed the pump packing without the area operator present.

What did they learn?

Verify you are in the correct plant by confirming the following plant identifiers:

- Signage at the entrance to each plant area e.g. K1 process, K1 utilities etc.

- Signage on the plant buildings and entrances e.g. K1 process pump.

- Verify the full equipment tag number (K1 equipment tag numbers begin with 1500 and K2 with 2500).

Follow work management standards for breaking containment:

- Confirm equipment location for ‘first break’ with the AO.

- Verify JSA and SWP checklist controls are in place before initialling as complete.

- The AO should be present for ‘first break’.

Ask yourself or your crew

Identify equipment that looks similar on your worksite. How do you check you are working on the equipment you are meant to be working on?

What controls are in place to stop this happening to you or your colleagues?

What improvements could you make to any processes you follow?

Have you ever witnessed your colleagues working on plant when they should be waiting for supervision? What did you do?

A work crew was changing packing on two pumps in the K2 plant. When they left to retrieve tools, they returned to K1 plant and broke containment on two pumps on ‘hot standby’.