-

What happened?

A worker was using a 4,000 pounds per square inch (maximum psi) pressure washer to clean a tank sump.

The worker attempted to adjust the hose when the water stream cut through his boot, causing a laceration.

The wound was contaminated with crude oil.

Surgery and overnight hospitalisation was required.

-

Why did it happen?

The viscous residual product needed to be agitated and removed with the help of a pressure washer and zero-tip nozzle.

The personal protective equipment assessment and requirements were not modified to include the use of the zero-tip nozzle.

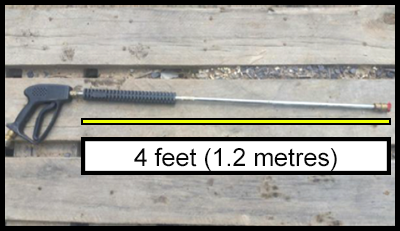

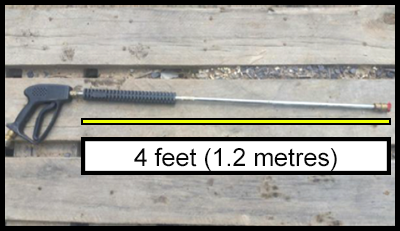

The length of the wand was short (1.2m/4ft), allowing it to come into contact with the worker’s foot.

-

What did they learn?

The PPE assessment was not adequate. Metatarsal guards would have prevented the injury.

The use of a 1.2m/4ft wand allowed for the operator to have his foot in the line of fire, which could have been prevented by using a longer wand.

Even at less than 4,000 psi, the use of a zero-tip nozzle increased the likelihood of damage to the boot and injury.

The use of fan-tip nozzles might have been better for the job as they distribute the pressure differently and reduce the risk of injury.

-

Ask yourself or your crew

What other actions could have been taken?

How could something like this happen here?

Would you say that our current requirements are adequate for the equipment we use?

What improvement can we make today to our personal protective equipment or way of working?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was using a 4,000 pounds per square inch (maximum psi) pressure washer to clean a tank sump.

The worker attempted to adjust the hose when the water stream cut through his boot, causing a laceration.

The wound was contaminated with crude oil.

Surgery and overnight hospitalisation was required.

Why did it happen?

The viscous residual product needed to be agitated and removed with the help of a pressure washer and zero-tip nozzle.

The personal protective equipment assessment and requirements were not modified to include the use of the zero-tip nozzle.

The length of the wand was short (1.2m/4ft), allowing it to come into contact with the worker’s foot.

What did they learn?

The PPE assessment was not adequate. Metatarsal guards would have prevented the injury.

The use of a 1.2m/4ft wand allowed for the operator to have his foot in the line of fire, which could have been prevented by using a longer wand.

Even at less than 4,000 psi, the use of a zero-tip nozzle increased the likelihood of damage to the boot and injury.

The use of fan-tip nozzles might have been better for the job as they distribute the pressure differently and reduce the risk of injury.

Ask yourself or your crew

What other actions could have been taken?

How could something like this happen here?

Would you say that our current requirements are adequate for the equipment we use?

What improvement can we make today to our personal protective equipment or way of working?

A worker was using a 4,000 pounds per square inch (maximum psi) pressure washer to clean a tank sump. The worker attempted to adjust the hose when the water stream cut through his boot, causing a laceration.