-

What happened?

Workers were offloading sulphur from the sulphur pit into trucks at the loading rack.

There was a blockage in the bypass line.

During the blockage identification process, a 900 elbow was removed, and an old tank valve was used as the try point.

After maintenance was completed, the open ends of the bypass lines were capped and bleeder blinds and valve tags were removed.

On the night shift, the bypass valve was opened to allow sulphur to access the bypass line (to ‘melt out’ the piping).

Molten sulphur sprayed out from the tank valve used as the try point, coating the pipe rack and diked area, with some leaking into a sewer drain.

-

Why did it happen?

The recommissioning procedure was not followed:

- The line was not walked down before starting the pump and opening the valve.

- The energy isolation device (EID) sheet was not signed and initialled to verify the opening and closing of the try points.

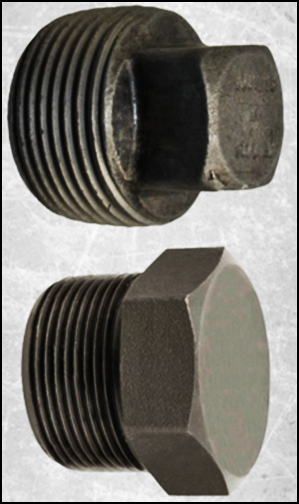

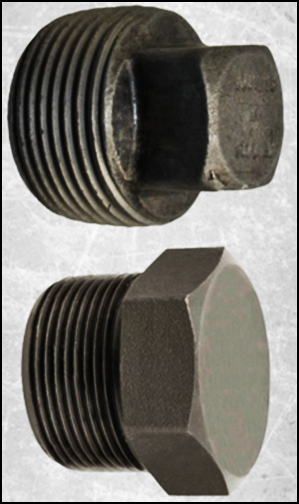

- There was no bull plug placed in the open bleeder after the job was completed.

-

What did they learn?

Make sure the recommissioning procedure is fully followed and includes:

- Walking down the line before starting the pump and opening the line.

- Signed off isolation device (EID) sheet.

- Placing the bull plugs in the open bleeder before completing the job.

Review and update the energy isolation device (EID) list to include the recommissioning checklist.

-

Ask yourself or your crew

How do you know you have all the checklists/paperwork you need to ensure you can do your job safely? What should you do if something is missing or is unclear?

Think of a time when something similar happened to you when/after unplugging a line.

- What happened?

- How could the incident have been avoided?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Workers were offloading sulphur from the sulphur pit into trucks at the loading rack.

There was a blockage in the bypass line.

During the blockage identification process, a 900 elbow was removed, and an old tank valve was used as the try point.

After maintenance was completed, the open ends of the bypass lines were capped and bleeder blinds and valve tags were removed.

On the night shift, the bypass valve was opened to allow sulphur to access the bypass line (to ‘melt out’ the piping).

Molten sulphur sprayed out from the tank valve used as the try point, coating the pipe rack and diked area, with some leaking into a sewer drain.

Why did it happen?

The recommissioning procedure was not followed:

- The line was not walked down before starting the pump and opening the valve.

- The energy isolation device (EID) sheet was not signed and initialled to verify the opening and closing of the try points.

- There was no bull plug placed in the open bleeder after the job was completed.

What did they learn?

Make sure the recommissioning procedure is fully followed and includes:

- Walking down the line before starting the pump and opening the line.

- Signed off isolation device (EID) sheet.

- Placing the bull plugs in the open bleeder before completing the job.

Review and update the energy isolation device (EID) list to include the recommissioning checklist.

Ask yourself or your crew

How do you know you have all the checklists/paperwork you need to ensure you can do your job safely? What should you do if something is missing or is unclear?

Think of a time when something similar happened to you when/after unplugging a line.

- What happened?

- How could the incident have been avoided?

Workers were offloading sulphur from the sulphur pit into trucks at the loading rack. There was a blockage in the bypass line which was repaired. Later that day the bypass valve was opened and molten sulphur sprayed out from the tank valve.