-

What happened?

Two incidents involving hammerhead tower cranes occurred.

Incident 1:

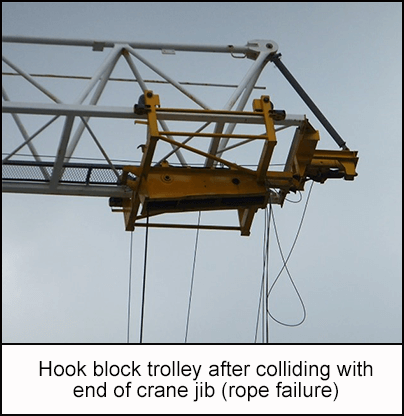

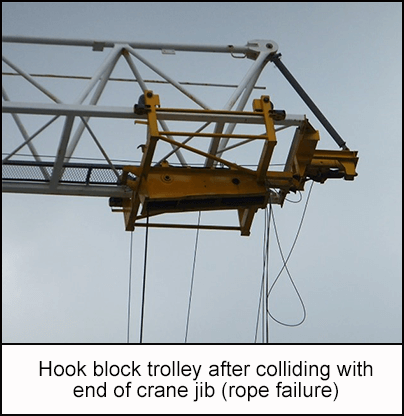

The hook block was being hoisted up and contacted the hook trolley (known as two blocking).

The falling hook trolley travelled along the jib at speed and collided with the jib end, causing damage to the crane.

The trolley rope was also cut in the incident. Both the hoist rope and trolley rope ends dropped onto the roof of a house next to the site.

The hoist rope was rigged in double fall, with the end of the hoist rope anchored to the end of the tower crane jib.

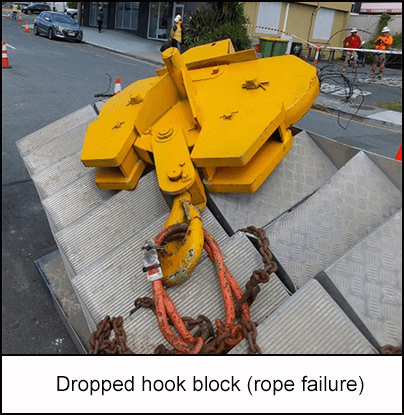

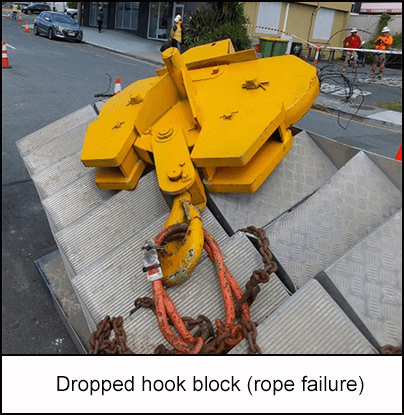

When the hoist rope catastrophically failed it dropped the hook block (500 kg/1102 lbs) to the ground.

Incident 2:

A crane operator was attempting to lower a 7-tonne skip onto the road.

The load started to free fall and the hoist brake was unable to hold the load.

The rubbish skip dropped 11 metres/36 feet.

-

Why did it happen?

In the first incident the main cause was the hoist limit of the crane not functioning.

- The hoisting limit switch system on a tower crane has a deceleration function that slows the hoisting speed down, and a final limit switch that stops the hook two blocking.

In the second incident, the hoist brake was unable to hold the load.

- There was no mechanical failure of the system (the hook block was later hoisted and held with no problem)

- The ability of the brake to hold the load is uncertain, the fault was established to be intermittent

-

What did they learn?

All manufacturer’s safety features should remain operational and not be overridden for normal operation of the crane.

- The only reason they could be temporarily overridden is for rigging purposes, including when the crane is commissioned, dismantled or the rigging set up on the hook block is being changed (e.g. some tower cranes can be changed from two to four rope falls).

Confirm that the hook height of the tower crane is high enough to carry out all duties without the need to override the crane’s safety features..

If a free fall of the crane winch is detected, the crane should be immediately removed from service and serviced by a competent person before being put back into use.

-

Ask yourself or your crew

How can something like this happen here?

Have you ever experienced a crane rope or brake failure?

Do you know the load and height limits of cranes used on your site? How can you check this?

Have you ever seen a crane operator override the manufacturer’s safety procedures? What did you do?

What checks should you carry out before starting any hoisting procedures?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Two incidents involving hammerhead tower cranes occurred.

Incident 1:

The hook block was being hoisted up and contacted the hook trolley (known as two blocking).

The falling hook trolley travelled along the jib at speed and collided with the jib end, causing damage to the crane.

The trolley rope was also cut in the incident. Both the hoist rope and trolley rope ends dropped onto the roof of a house next to the site.

The hoist rope was rigged in double fall, with the end of the hoist rope anchored to the end of the tower crane jib.

When the hoist rope catastrophically failed it dropped the hook block (500 kg/1102 lbs) to the ground.

Incident 2:

A crane operator was attempting to lower a 7-tonne skip onto the road.

The load started to free fall and the hoist brake was unable to hold the load.

The rubbish skip dropped 11 metres/36 feet.

Why did it happen?

In the first incident the main cause was the hoist limit of the crane not functioning.

- The hoisting limit switch system on a tower crane has a deceleration function that slows the hoisting speed down, and a final limit switch that stops the hook two blocking.

In the second incident, the hoist brake was unable to hold the load.

- There was no mechanical failure of the system (the hook block was later hoisted and held with no problem)

- The ability of the brake to hold the load is uncertain, the fault was established to be intermittent

What did they learn?

All manufacturer’s safety features should remain operational and not be overridden for normal operation of the crane.

- The only reason they could be temporarily overridden is for rigging purposes, including when the crane is commissioned, dismantled or the rigging set up on the hook block is being changed (e.g. some tower cranes can be changed from two to four rope falls).

Confirm that the hook height of the tower crane is high enough to carry out all duties without the need to override the crane’s safety features..

If a free fall of the crane winch is detected, the crane should be immediately removed from service and serviced by a competent person before being put back into use.

Ask yourself or your crew

How can something like this happen here?

Have you ever experienced a crane rope or brake failure?

Do you know the load and height limits of cranes used on your site? How can you check this?

Have you ever seen a crane operator override the manufacturer’s safety procedures? What did you do?

What checks should you carry out before starting any hoisting procedures?

This is a description of two incidents involving hammerhead tower cranes. In the first incident, the hoist rope failed, and in the second, the hoist brake was unable to hold the load.