-

What happened?

Wells crew were lifting an oil drum containing 208l (46gal) of oil to the drill floor.

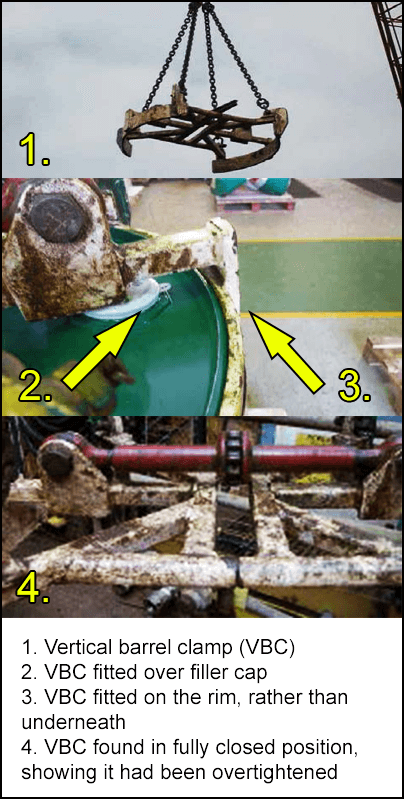

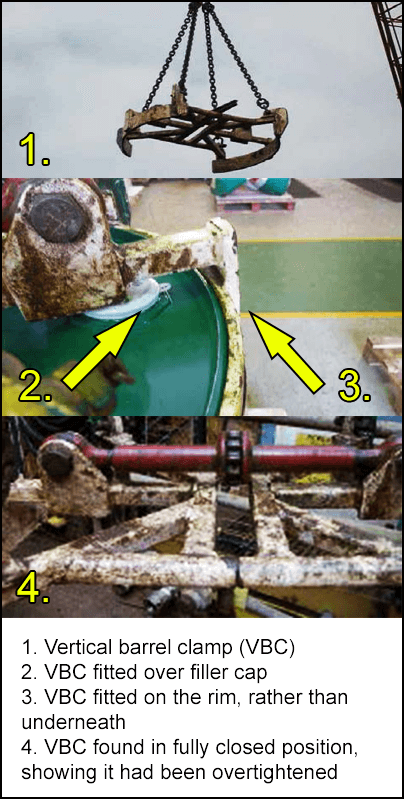

They were using a vertical barrel clamp (VBC) connected to a crane.

Drum was attached to the VBC and checked by the drilling deck foreman (DDF).

Crane operator (CO) was moving the drum to its location.

As it was being placed onto the drill derrick catwalk, the oil drum fell out of the VBC 15m (50ft) to the drill floor.

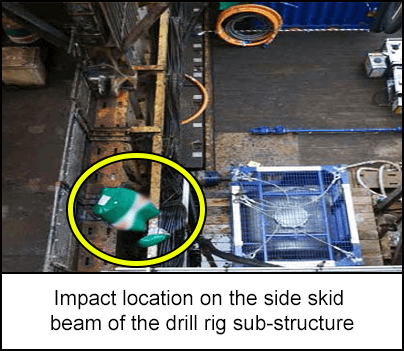

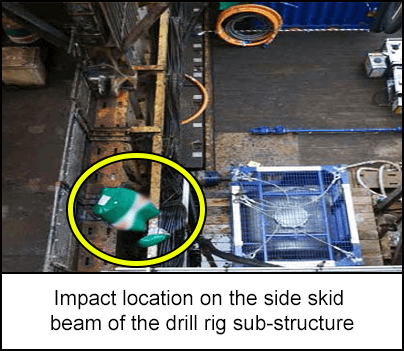

The drum hit a side skid beam of the drill rig sub-structure.

No injuries or environmental consequence, but the oil drum had the potential to cause one fatality (by striking one electrician working in the area).

-

Why did it happen?

VBC was incorrectly fitted to the drum:

- VBC was fitted over the top of the filler caps on the lid of the drum. This meant that both clamps could not be installed under the rims of the drum as required.

- VBC was also in the fully closed position. This overtightened the VBC and deformed the drum.

Drum worked itself free from the clamp due to the deformity of the drum, incorrect position of the clamps, weight of the drum and motion during the lift.

Poor safety procedures and practice on site:

- No risk assessment or proper lift plan were carried out.

- Inadequate checks to ensure personnel is out of the line of fire during the lift.

- Banksman duties were not carried out adequately. Crane operator was made responsible once the load was clear of the deck (contrary to procedure and industry training).

Manufacturer instructions did not identify precautions for installing the clamp over filler caps and how that would lead to overtightening.

-

What did they learn?

Ensure VBCs are installed and used according to manufacturer’s recommendations and best practice available.

Ensure risk assessments and lift plans are in place, discussed and understood by all personnel involved.

All personnel should adhere to the procedures in place.

-

Ask yourself or your crew

What is the correct way to fit VBCs?

- What procedures do we have for this equipment?

What do we consider when planning a lifting operation (load, risk assessment, safety measures etc.)?

Why shouldn’t the banksman have passed on his duties to the crane operator?

What should you do if your colleague is working in an unsafe manner?

Is non-compliance punishable on our site? If not, should it be?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Wells crew were lifting an oil drum containing 208l (46gal) of oil to the drill floor.

They were using a vertical barrel clamp (VBC) connected to a crane.

Drum was attached to the VBC and checked by the drilling deck foreman (DDF).

Crane operator (CO) was moving the drum to its location.

As it was being placed onto the drill derrick catwalk, the oil drum fell out of the VBC 15m (50ft) to the drill floor.

The drum hit a side skid beam of the drill rig sub-structure.

No injuries or environmental consequence, but the oil drum had the potential to cause one fatality (by striking one electrician working in the area).

Why did it happen?

VBC was incorrectly fitted to the drum:

- VBC was fitted over the top of the filler caps on the lid of the drum. This meant that both clamps could not be installed under the rims of the drum as required.

- VBC was also in the fully closed position. This overtightened the VBC and deformed the drum.

Drum worked itself free from the clamp due to the deformity of the drum, incorrect position of the clamps, weight of the drum and motion during the lift.

Poor safety procedures and practice on site:

- No risk assessment or proper lift plan were carried out.

- Inadequate checks to ensure personnel is out of the line of fire during the lift.

- Banksman duties were not carried out adequately. Crane operator was made responsible once the load was clear of the deck (contrary to procedure and industry training).

Manufacturer instructions did not identify precautions for installing the clamp over filler caps and how that would lead to overtightening.

What did they learn?

Ensure VBCs are installed and used according to manufacturer’s recommendations and best practice available.

Ensure risk assessments and lift plans are in place, discussed and understood by all personnel involved.

All personnel should adhere to the procedures in place.

Ask yourself or your crew

What is the correct way to fit VBCs?

- What procedures do we have for this equipment?

What do we consider when planning a lifting operation (load, risk assessment, safety measures etc.)?

Why shouldn’t the banksman have passed on his duties to the crane operator?

What should you do if your colleague is working in an unsafe manner?

Is non-compliance punishable on our site? If not, should it be?

A crew were lifting an oil drum using a vertical barrel clamp (VBC). The clamp was fitted incorrectly, allowing the drum to fall 15m (50ft). There were no injuries to personnel or any environmental consequence, but the oil drum had the potential to cause one fatality (by striking one electrician working in the area).