-

What happened?

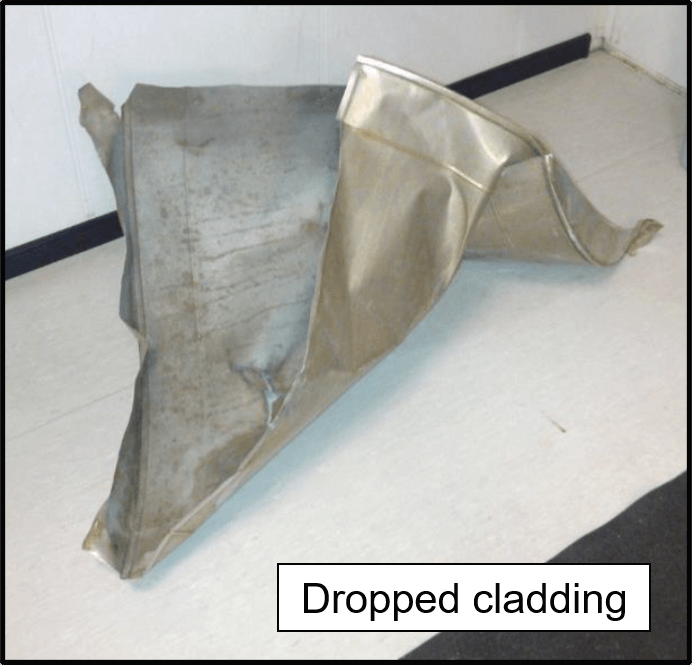

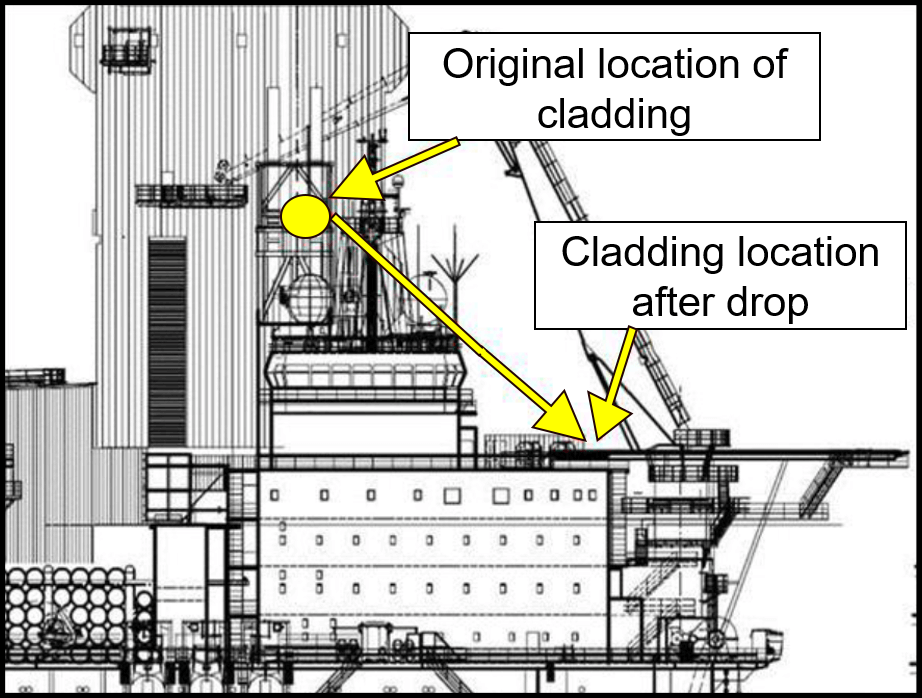

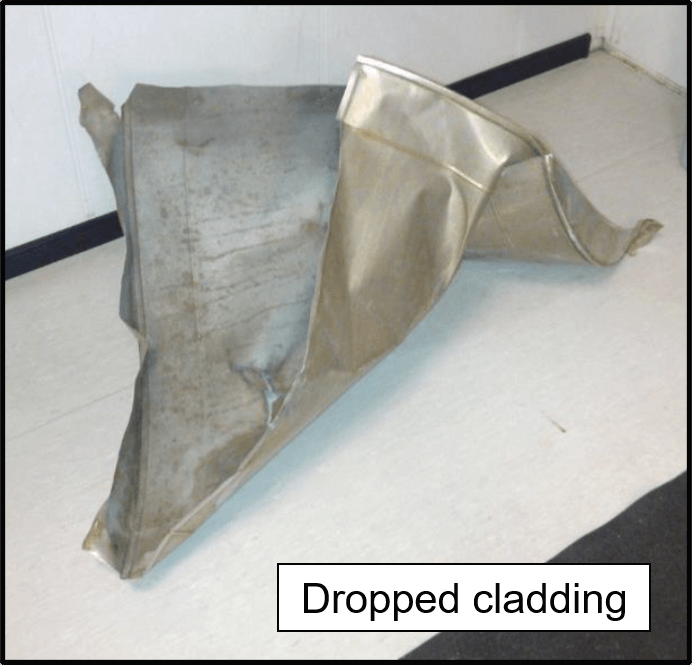

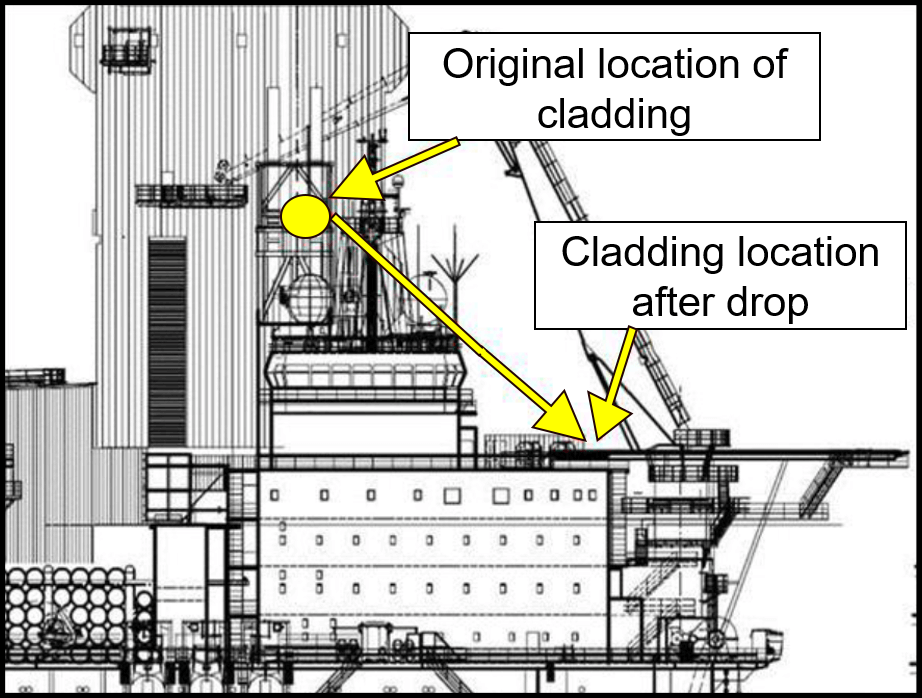

During a period of high winds (mean 34 knots, gusting 45 knots) a section of aluminium cladding weighing 4 kg (8.8 lb) came loose from its fixings and fell 4 m (13 feet) from an exhaust funnel, landing close to a frequently used walkway.

Several self-tapping screws were found lying loose at the base of the exhaust.

The object had the potential to cause serious or fatal injuries due to its height, weight and sharp edges.

-

Why did it happen?

Following a weather forecast, ‘bad weather’ checklists were issued to identify and secure any potential loose equipment, which included the engine exhaust funnels. However, there was no evidence this check had been carried out.

Inspection found that the detached section of cladding was secured with self-tapping screws, but other sections that were secured with rivets remained in position. There were also open seams and missing sealant on other funnels.

Checklists did not include specific guidance on what to inspect e.g. fixing screws are secure.

There was no specific inspection and maintenance routine for the exhaust funnels.

-

What did they learn?

Engineering controls:

- Ensure the design and securing of cladding exposed to high winds is suitable and sufficient.

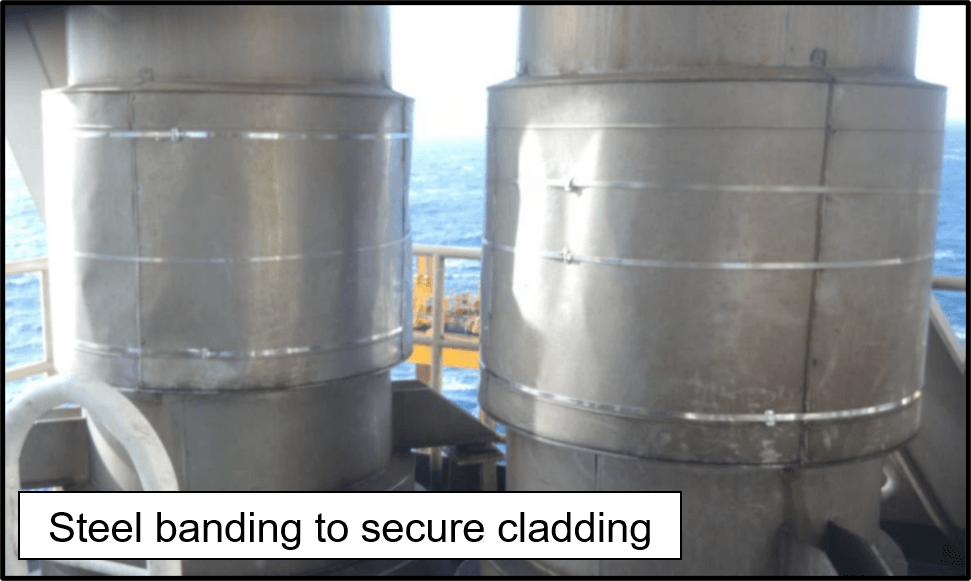

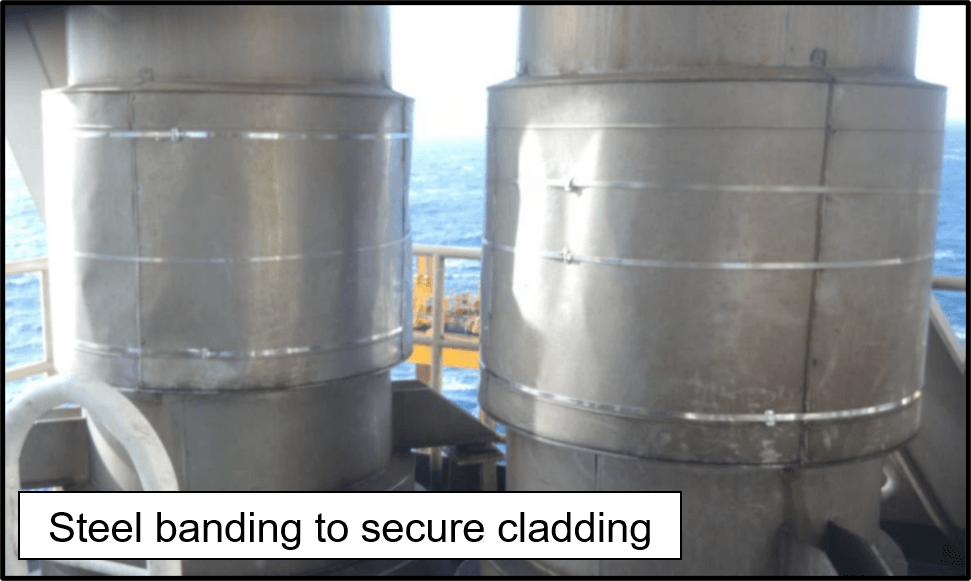

- Consider the use of secondary retention where there is a known risk of dropped objects, e.g. steel banding used to further secure the cladding (see image).

Administrative controls:

- Drops inspection programmes, including bad weather checklists, should extend beyond the derrick, covering other at-risk areas such as exhaust stacks and cranes.

- Exhaust funnels should be included in periodic maintenance and inspection routines.

-

Ask yourself or your crew

How could something like this happen here?

How well secured is our equipment against bad weather?

How do we know a bad weather check has been carried out?

How effective are our inspection and maintenance programs at preventing drops/falling objects?

What can we change to eliminate or reduce the risk of drops?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a period of high winds (mean 34 knots, gusting 45 knots) a section of aluminium cladding weighing 4 kg (8.8 lb) came loose from its fixings and fell 4 m (13 feet) from an exhaust funnel, landing close to a frequently used walkway.

Several self-tapping screws were found lying loose at the base of the exhaust.

The object had the potential to cause serious or fatal injuries due to its height, weight and sharp edges.

Why did it happen?

Following a weather forecast, ‘bad weather’ checklists were issued to identify and secure any potential loose equipment, which included the engine exhaust funnels. However, there was no evidence this check had been carried out.

Inspection found that the detached section of cladding was secured with self-tapping screws, but other sections that were secured with rivets remained in position. There were also open seams and missing sealant on other funnels.

Checklists did not include specific guidance on what to inspect e.g. fixing screws are secure.

There was no specific inspection and maintenance routine for the exhaust funnels.

What did they learn?

Engineering controls:

- Ensure the design and securing of cladding exposed to high winds is suitable and sufficient.

- Consider the use of secondary retention where there is a known risk of dropped objects, e.g. steel banding used to further secure the cladding (see image).

Administrative controls:

- Drops inspection programmes, including bad weather checklists, should extend beyond the derrick, covering other at-risk areas such as exhaust stacks and cranes.

- Exhaust funnels should be included in periodic maintenance and inspection routines.

Ask yourself or your crew

How could something like this happen here?

How well secured is our equipment against bad weather?

How do we know a bad weather check has been carried out?

How effective are our inspection and maintenance programs at preventing drops/falling objects?

What can we change to eliminate or reduce the risk of drops?

Following bad weather, funnel cladding dropped 4 meters.