-

What happened?

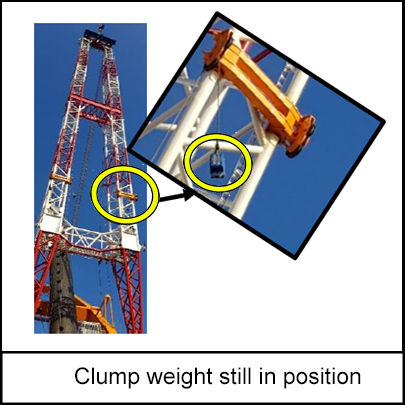

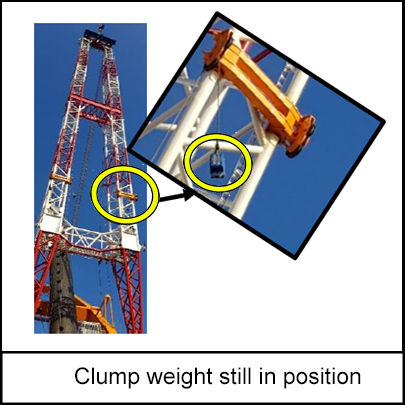

A crane boom was lowered towards the cradle for sea fastening before transit.

When the crane operator stopped to verify with the camera that the boom was in the correct position, his elbow unintentionally hit the tugger winch lever.

The winch started pulling on the tugger wire and pulled the rigging (including wedge socket) onto the sheave in the boom.

The wedge socket, shackle and a 750kg (1673 lbs) clump weight dropped 30 m (98.5 ft) onto the deck.

It landed 1m (3 ft) away from where a worker was standing.

The tugger wire also went through the sheave and landed against the gangway.

-

Why did it happen?

Poor design - the lever of the tugger winch was positioned close to the elbow.

Lack of safeguards to prevent unintentional activation of the tugger winch by operator. The operator leaned forward to look at the boom as the camera visibility was reduced by darkness, wind, rain and lights glare.

A wedge socket was recently introduced into the rigging configuration (changed from original spelter socket).

Lack of mechanisms to stop rigging being pulled onto the sheave. The wedge that was part of the rigging was pushed down when the sheave made contact, releasing the tension on the wire. As a result, the wire was pulled out of the wedge socket.

-

What did they learn?

The below actions should be evaluated for each operator cabin (e.g. earth moving equipment, winches, etc.):

- Verify if controls can be activated unintentionally and consider the potential consequences.

- Evaluate if there are mechanisms in place to stop equipment from making contact (e.g. limit switches).

- Consider what the weakest component is in the equipment configuration and what the consequence might be if it fails.

-

Ask yourself or your crew

Think about our equipment. How could someone make a similar error? (E.g. wrong button pressed, or inadvertently pressed)

Is our equipment fitted with controls to avoid unintentional activation? If not, what can we do to reduce the risk?

How did we establish the exclusion zone? Where can you safely stand?

If there is a change to how we work (e.g. our rigging configuration), what can we do to ensure management of change is followed?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A crane boom was lowered towards the cradle for sea fastening before transit.

When the crane operator stopped to verify with the camera that the boom was in the correct position, his elbow unintentionally hit the tugger winch lever.

The winch started pulling on the tugger wire and pulled the rigging (including wedge socket) onto the sheave in the boom.

The wedge socket, shackle and a 750kg (1673 lbs) clump weight dropped 30 m (98.5 ft) onto the deck.

It landed 1m (3 ft) away from where a worker was standing.

The tugger wire also went through the sheave and landed against the gangway.

Why did it happen?

Poor design - the lever of the tugger winch was positioned close to the elbow.

Lack of safeguards to prevent unintentional activation of the tugger winch by operator. The operator leaned forward to look at the boom as the camera visibility was reduced by darkness, wind, rain and lights glare.

A wedge socket was recently introduced into the rigging configuration (changed from original spelter socket).

Lack of mechanisms to stop rigging being pulled onto the sheave. The wedge that was part of the rigging was pushed down when the sheave made contact, releasing the tension on the wire. As a result, the wire was pulled out of the wedge socket.

What did they learn?

The below actions should be evaluated for each operator cabin (e.g. earth moving equipment, winches, etc.):

- Verify if controls can be activated unintentionally and consider the potential consequences.

- Evaluate if there are mechanisms in place to stop equipment from making contact (e.g. limit switches).

- Consider what the weakest component is in the equipment configuration and what the consequence might be if it fails.

Ask yourself or your crew

Think about our equipment. How could someone make a similar error? (E.g. wrong button pressed, or inadvertently pressed)

Is our equipment fitted with controls to avoid unintentional activation? If not, what can we do to reduce the risk?

How did we establish the exclusion zone? Where can you safely stand?

If there is a change to how we work (e.g. our rigging configuration), what can we do to ensure management of change is followed?

A crane boom was lowered towards the cradle for sea fastening before transit. The crane operator unintentionally hit the tugger winch lever, causing the wedge socket, shackle and the clump weight to drop onto the deck. It landed 1m (3 ft) away from where a worker was standing.