-

What happened?

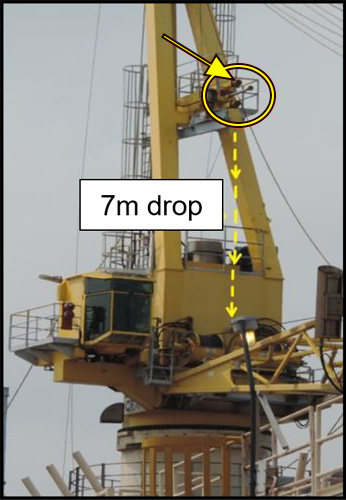

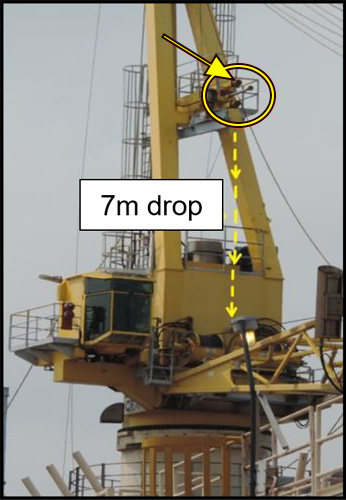

During a pre-use inspection by a crane operator, a crane boom buffer (a foam cylinder impact absorber weighing 3kgs / 6.6lb) was found lying on the grating of the whip line and main block drums.

It had separated from its mount and fell 7 meters / 23 feet onto the drum platform below. It could have caused serious injury or damage.

The crane was last used two days before the incident, and the pre-use inspection did not identify any issues with the boom buffers.

The use of the crane stopped until safe operation was confirmed.

-

Why did it happen?

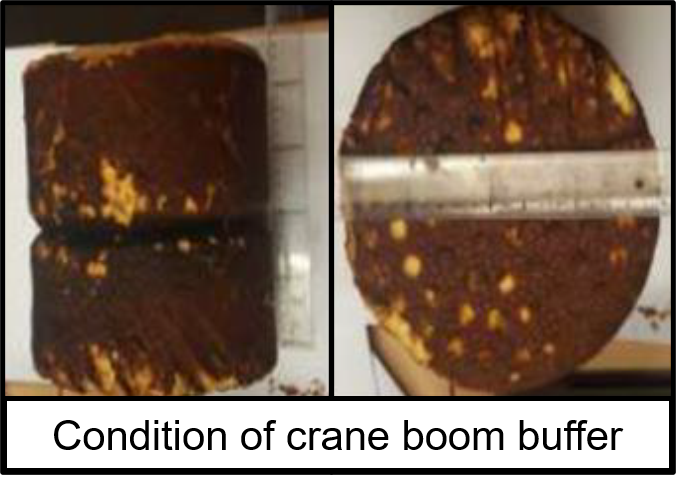

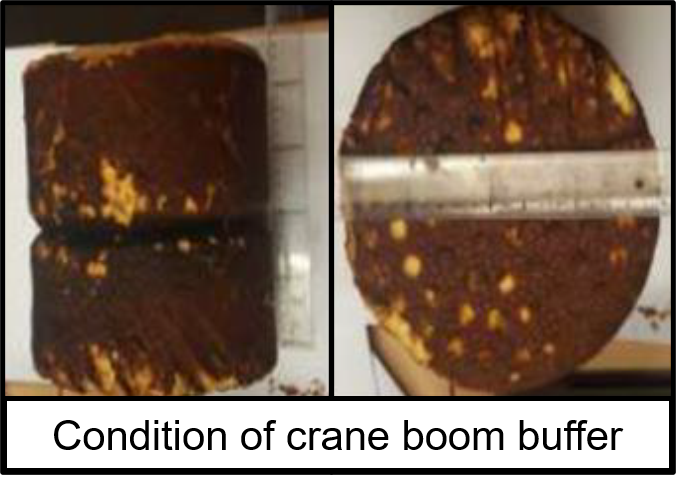

The boom buffer had deteriorated due to exposure to the weather conditions.

Visual inspection of the condition of the buffers is conducted as part of crane preventive maintenance. However, the visual inspection method did not adequately cover the possible failure modes of the buffers.

The original equipment manufacturer (OEM) does not provide recommendations on how frequently buffers should be replaced. The boom buffers were last replaced several years ago after a detailed physical inspection.

-

What did they learn?

A new buffer design is now available with a more secure connection and an integral tether to catch the buffer if it is knocked off. Consider changing out to this new design.

Physically inspect the condition of buffers on cranes – in addition to visual inspection.

Ensure that buffer inspections (both physical and visual) are carried out at the appropriate frequency.

Review the frequency of buffer change outs.

-

Ask yourself or your crew

How could something like this happen here?

How might our on-site inspections miss something like this?

What barriers do we have in place that prevent or mitigate against falling items of equipment?

How effective is our lifting equipment inspection programme, for detecting signs of deterioration? How do we know?

How do we keep up-to-date with new designs and improvements for lifting equipment?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a pre-use inspection by a crane operator, a crane boom buffer (a foam cylinder impact absorber weighing 3kgs / 6.6lb) was found lying on the grating of the whip line and main block drums.

It had separated from its mount and fell 7 meters / 23 feet onto the drum platform below. It could have caused serious injury or damage.

The crane was last used two days before the incident, and the pre-use inspection did not identify any issues with the boom buffers.

The use of the crane stopped until safe operation was confirmed.

Why did it happen?

The boom buffer had deteriorated due to exposure to the weather conditions.

Visual inspection of the condition of the buffers is conducted as part of crane preventive maintenance. However, the visual inspection method did not adequately cover the possible failure modes of the buffers.

The original equipment manufacturer (OEM) does not provide recommendations on how frequently buffers should be replaced. The boom buffers were last replaced several years ago after a detailed physical inspection.

What did they learn?

A new buffer design is now available with a more secure connection and an integral tether to catch the buffer if it is knocked off. Consider changing out to this new design.

Physically inspect the condition of buffers on cranes – in addition to visual inspection.

Ensure that buffer inspections (both physical and visual) are carried out at the appropriate frequency.

Review the frequency of buffer change outs.

Ask yourself or your crew

How could something like this happen here?

How might our on-site inspections miss something like this?

What barriers do we have in place that prevent or mitigate against falling items of equipment?

How effective is our lifting equipment inspection programme, for detecting signs of deterioration? How do we know?

How do we keep up-to-date with new designs and improvements for lifting equipment?

A crane boom buffer fell 7 meters. Pre-use inspection had not detected any issues.