-

What happened?

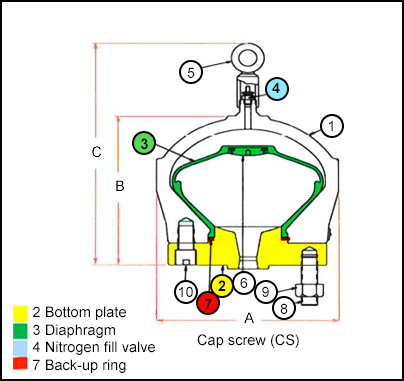

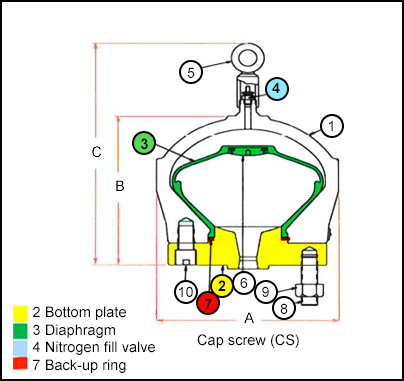

A worker was repairing a pulsation dampener wash water pump.

When he removed the bottom plate, the rubber diaphragm exited the housing and landed 3m/10ft away.

Luckily, no one was injured.

-

Why did it happen?

Water pump was still under nitrogen pressure when the bottom plate was removed.

Worker assumed that the pump failure was caused by a failed diaphragm (often the problem in the past), where nitrogen pressure would not be present.

Worker expected that the pump bladder failed and did not check the pressure.

Work permit did not include depressurising the dampener due to a lack of understanding of how it worked.

-

What did they learn?

All workers should understand how the equipment works and what are the risks.

Create a procedure for maintenance work pulsation dampeners / update existing procedure to include depressurising pulsation dampeners.

Consider modifying the original equipment manufacturer’s (OEM’s) documentation to clearly identify the dampener and remove non-essential information to avoid confusion when assembling or during maintenance.

-

Ask yourself or your crew

How do you stop yourself presuming what might the problem?

How do you check pumps/other pressurised equipment to ensure energy isolation before starting work?

What should you do if you don’t fully understand the equipment you have to work on today?

What measures do we have in place to prevent this from happening on our site? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A worker was repairing a pulsation dampener wash water pump.

When he removed the bottom plate, the rubber diaphragm exited the housing and landed 3m/10ft away.

Luckily, no one was injured.

Why did it happen?

Water pump was still under nitrogen pressure when the bottom plate was removed.

Worker assumed that the pump failure was caused by a failed diaphragm (often the problem in the past), where nitrogen pressure would not be present.

Worker expected that the pump bladder failed and did not check the pressure.

Work permit did not include depressurising the dampener due to a lack of understanding of how it worked.

What did they learn?

All workers should understand how the equipment works and what are the risks.

Create a procedure for maintenance work pulsation dampeners / update existing procedure to include depressurising pulsation dampeners.

Consider modifying the original equipment manufacturer’s (OEM’s) documentation to clearly identify the dampener and remove non-essential information to avoid confusion when assembling or during maintenance.

Ask yourself or your crew

How do you stop yourself presuming what might the problem?

How do you check pumps/other pressurised equipment to ensure energy isolation before starting work?

What should you do if you don’t fully understand the equipment you have to work on today?

What measures do we have in place to prevent this from happening on our site? How can we improve?

During maintenance work on a pulsation dampener wash water pump, a worker removed the bottom plate without realising that the pump was under nitrogen pressure. The rubber diaphragm exited the housing and landed 3m/10ft away. Luckily, no one was injured.