-

What happened?

A fire was discovered on a motor and pump base.

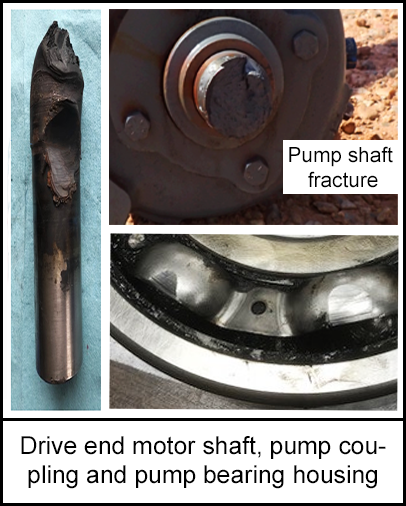

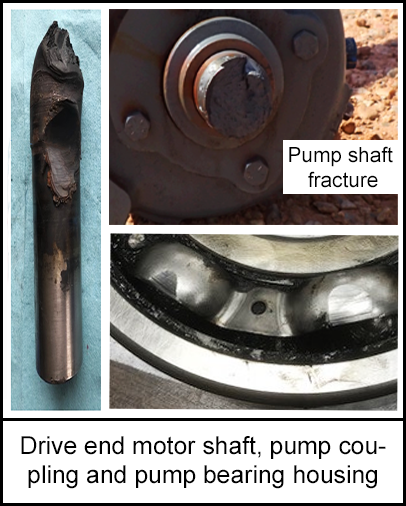

The motor shaft melted and broke loose:

₋ motor shaft was found disconnected from the pump coupling.

₋ pump coupling was found on the platform structure above the pump and motor.

₋ pump inboard bearing housing was found 29m (96ft) from the pump base.

There was no loss of hydrocarbon containment from the dual seal natural gas liquid (NGL) pump.

The incident had potential for injury and loss of containment

-

Why did it happen?

A riveted roller bearing cage failure on the motor inboard bearing (drive end motor) shaft caused excess heat, causing the motor shaft to melt and break loose.

Vibration analysis systems did not identify the bearing cage failure prior to shaft failure.

A dual shield bearing was installed in a single shield application. This was not identified by the motor repair shop, nor specified during the previous replacement order.

The motor’s outboard bearing (OB) was missing a rivet from the bearing cage – supplied from the third-party repair shop.

-

What did they learn?

Ensure correct shields are installed as per specifications.

Improve third party repair shop quality assurance and control before shipping parts so there are no missing components.

-

Ask yourself or your crew

Has anything like this happened in your workplace?

Do your warning systems pick up on all possible hazards?

How do you know that parts for installation are fully fit for purpose? Is there a formal checking process?

What measures do we have in place to avoid something similar on our site? What else could we do?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A fire was discovered on a motor and pump base.

The motor shaft melted and broke loose:

₋ motor shaft was found disconnected from the pump coupling.

₋ pump coupling was found on the platform structure above the pump and motor.

₋ pump inboard bearing housing was found 29m (96ft) from the pump base.

There was no loss of hydrocarbon containment from the dual seal natural gas liquid (NGL) pump.

The incident had potential for injury and loss of containment

Why did it happen?

A riveted roller bearing cage failure on the motor inboard bearing (drive end motor) shaft caused excess heat, causing the motor shaft to melt and break loose.

Vibration analysis systems did not identify the bearing cage failure prior to shaft failure.

A dual shield bearing was installed in a single shield application. This was not identified by the motor repair shop, nor specified during the previous replacement order.

The motor’s outboard bearing (OB) was missing a rivet from the bearing cage – supplied from the third-party repair shop.

What did they learn?

Ensure correct shields are installed as per specifications.

Improve third party repair shop quality assurance and control before shipping parts so there are no missing components.

Ask yourself or your crew

Has anything like this happened in your workplace?

Do your warning systems pick up on all possible hazards?

How do you know that parts for installation are fully fit for purpose? Is there a formal checking process?

What measures do we have in place to avoid something similar on our site? What else could we do?

A fire was discovered on a motor and pump base, caused by excess heat from a riveted roller bearing cage failure.