-

What happened?

A 100-tonne crawler crane was lifting a 16-tonne concrete wall panel.

The wall panel was fitted with 4 lifting inserts and equalising sheaves to balance its weight.

The lifting clutch link on one of the 5-tonne lifting clutches failed.

When the clutch link broke, two of the lifting points were ineffective and the panel dropped to the ground.

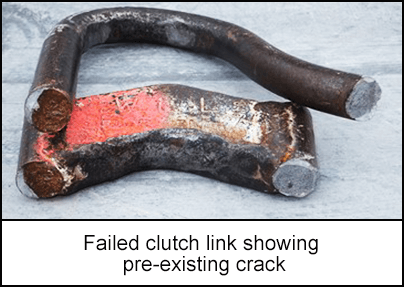

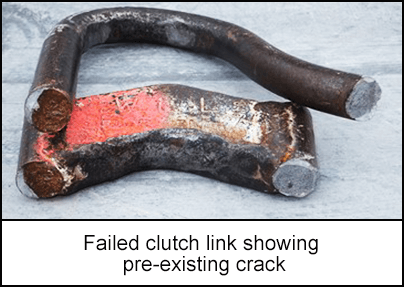

No workers were injured, but there was extensive damage to the panel (see image).

-

Why did it happen?

The primary cause of the lifting clutch link failure was a large, undetected crack through its cross-section.

The crack had rust on it which shows it had been there for a long time.

The crack was close to a weld on the inside of the clutch link, so it may have been difficult to notice on visual inspection (it had been inspected and tested 6 months before the incident).

-

What did they learn?

Workers should use a back-up lifting system for lifting pre-cast items.

Rigging crews should carry out their own detailed visual inspection of the lifting gear before using it.

Improve the testing regime for lifting clutches (e.g. introduce non-destructive (NDT) testing at 12-month checks, not only at manufacture).

The inspections should include measurement checking to determine that tolerances are still within manufacturer’s guidelines.

Inspection records should be maintained for every lifting clutch and should include:

- identification number of each clutch assembly

- inspection organisation carrying out the 12-monthly inspection

- name of the competent person carrying out the inspection

- inspection method used (including the NDT method if used)

- results of the inspection (e.g. pass/fail).

-

Ask yourself or your crew

How can something like this happen here?

What checks do you carry out on your lifting equipment before using it?

- What standards should you refer to when checking the equipment?

How often do we carry out non-destructive testing on our lifting equipment? How can we improve?

What other risks are associated with lifting operations?

What measures do we have in place to prevent something similar happening on our site? What else could we implement?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A 100-tonne crawler crane was lifting a 16-tonne concrete wall panel.

The wall panel was fitted with 4 lifting inserts and equalising sheaves to balance its weight.

The lifting clutch link on one of the 5-tonne lifting clutches failed.

When the clutch link broke, two of the lifting points were ineffective and the panel dropped to the ground.

No workers were injured, but there was extensive damage to the panel (see image).

Why did it happen?

The primary cause of the lifting clutch link failure was a large, undetected crack through its cross-section.

The crack had rust on it which shows it had been there for a long time.

The crack was close to a weld on the inside of the clutch link, so it may have been difficult to notice on visual inspection (it had been inspected and tested 6 months before the incident).

What did they learn?

Workers should use a back-up lifting system for lifting pre-cast items.

Rigging crews should carry out their own detailed visual inspection of the lifting gear before using it.

Improve the testing regime for lifting clutches (e.g. introduce non-destructive (NDT) testing at 12-month checks, not only at manufacture).

The inspections should include measurement checking to determine that tolerances are still within manufacturer’s guidelines.

Inspection records should be maintained for every lifting clutch and should include:

- identification number of each clutch assembly

- inspection organisation carrying out the 12-monthly inspection

- name of the competent person carrying out the inspection

- inspection method used (including the NDT method if used)

- results of the inspection (e.g. pass/fail).

Ask yourself or your crew

How can something like this happen here?

What checks do you carry out on your lifting equipment before using it?

- What standards should you refer to when checking the equipment?

How often do we carry out non-destructive testing on our lifting equipment? How can we improve?

What other risks are associated with lifting operations?

What measures do we have in place to prevent something similar happening on our site? What else could we implement?

A 100-tonne crawler crane was lifting a 16-tonne concrete panel when a lifting clutch failed. The panel dropped to the ground and was extensively damaged.