-

What happened?

A vessel was conducting a canal transit. A crane was used to lift a small boat into and out of the water.

After clearing the canal, the crane had to be secured for sea.

As the crane slewed to the right, a composite block, forming the end stop topping of the crane, fell from the top of the crane (a height of 20 metres/65 feet).

Several crew members were within 4 metres/13 feet of where it had landed. No one was injured.

-

Why did it happen?

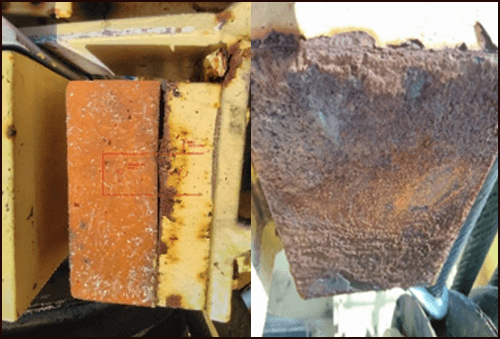

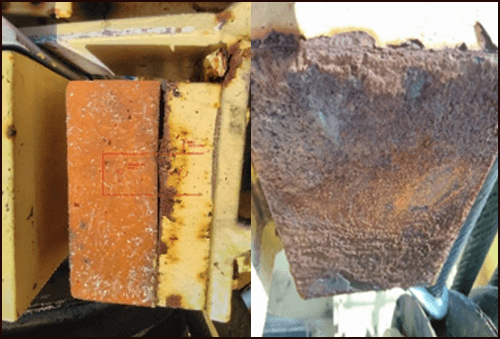

An investigation revealed that the composite block was glued, instead of drilled and fastened to the crane.

Rust formed between the steel plate of the crane and the composite block, which loosened it and caused it to fall off.

The root causes identified were:

- material failure

- inadequate design

- inadequate maintenance

An inspection was made of the aft crane, where a similar gap was observed between the steel plate and the composite block.

-

What did they learn?

Check cranes for loose or potentially loose objects, rust and corrosion and consider engineered solutions to any potential problems identified.

Consider the area immediately around the crane to be a potential dropped object zone.

Conduct a fresh dropped object survey on vessels.

-

Ask yourself or your crew

How can something like this happen here?

How do we ensure that objects at height are secured?

What lifting controls do we have in place that could have prevented this incident – of prevented the potential consequences?

How can we improve these controls?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A vessel was conducting a canal transit. A crane was used to lift a small boat into and out of the water.

After clearing the canal, the crane had to be secured for sea.

As the crane slewed to the right, a composite block, forming the end stop topping of the crane, fell from the top of the crane (a height of 20 metres/65 feet).

Several crew members were within 4 metres/13 feet of where it had landed. No one was injured.

Why did it happen?

An investigation revealed that the composite block was glued, instead of drilled and fastened to the crane.

Rust formed between the steel plate of the crane and the composite block, which loosened it and caused it to fall off.

The root causes identified were:

- material failure

- inadequate design

- inadequate maintenance

An inspection was made of the aft crane, where a similar gap was observed between the steel plate and the composite block.

What did they learn?

Check cranes for loose or potentially loose objects, rust and corrosion and consider engineered solutions to any potential problems identified.

Consider the area immediately around the crane to be a potential dropped object zone.

Conduct a fresh dropped object survey on vessels.

Ask yourself or your crew

How can something like this happen here?

How do we ensure that objects at height are secured?

What lifting controls do we have in place that could have prevented this incident – of prevented the potential consequences?

How can we improve these controls?

A composite block fell 20m metres/65 feet from the top of a crane during a canal transit. Several crew members were within 4 metres/13 feet of where it landed, however no one was injured.