-

What happened?

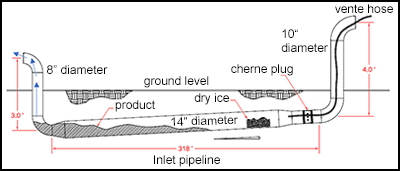

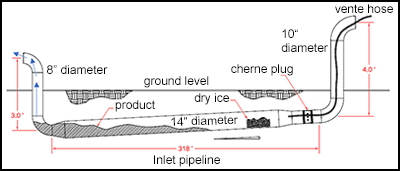

During repair of a tank, the 10 inch riser on the inlet piping was being replaced.

At the other end of the piping, the 8 inch riser was disconnected from the header to vent dry ice gas.

In preparation for welding, 15-20 pounds of dry ice and a Cherne plug with a small diameter vent hose were inserted in 10 inch riser.

Before welding began, an employee observed 3.5 barrels of jet fuel on the ground that had leaked from the 8 inch riser.

-

Why did it happen?

Drawings could not be found, so it was assumed that the underground piping was also 10 inches.

Local drawings were later found showing it was actually 14 inches, meaning it held a lot more jet fuel than anticipated.

The slope of the underground piping caused fuel to pool at the 8 inch riser low end, forming a liquid seal.

When the rate of dry ice sublimation exceeded the venting capacity of the plug vent hose, the CO2 gas pushed the 3.5 barrels of fuel out the 8 inch riser.

The amount of fluid was enough to form a channel for additional CO2 gas to vent, without releasing additional fuel.

-

What did they learn?

It is important to obtaining accurate drawings of piping.

If drawings are not in a central repository, try to find them locally or from engineering companies.

Dry ice will expand to 845 times its solid volume when it warms up and turns to gas. It is imperative to know what will happen to that gas to avoid incidents.

-

Ask yourself or your crew

How can something like this happen here?

What actions could have been taken to prevent this incident?

How can we obtain accurate piping drawings?

What can we do if drawings are not available?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During repair of a tank, the 10 inch riser on the inlet piping was being replaced.

At the other end of the piping, the 8 inch riser was disconnected from the header to vent dry ice gas.

In preparation for welding, 15-20 pounds of dry ice and a Cherne plug with a small diameter vent hose were inserted in 10 inch riser.

Before welding began, an employee observed 3.5 barrels of jet fuel on the ground that had leaked from the 8 inch riser.

Why did it happen?

Drawings could not be found, so it was assumed that the underground piping was also 10 inches.

Local drawings were later found showing it was actually 14 inches, meaning it held a lot more jet fuel than anticipated.

The slope of the underground piping caused fuel to pool at the 8 inch riser low end, forming a liquid seal.

When the rate of dry ice sublimation exceeded the venting capacity of the plug vent hose, the CO2 gas pushed the 3.5 barrels of fuel out the 8 inch riser.

The amount of fluid was enough to form a channel for additional CO2 gas to vent, without releasing additional fuel.

What did they learn?

It is important to obtaining accurate drawings of piping.

If drawings are not in a central repository, try to find them locally or from engineering companies.

Dry ice will expand to 845 times its solid volume when it warms up and turns to gas. It is imperative to know what will happen to that gas to avoid incidents.

Ask yourself or your crew

How can something like this happen here?

What actions could have been taken to prevent this incident?

How can we obtain accurate piping drawings?

What can we do if drawings are not available?

During repair of a tank, the 10 inch riser on the inlet piping was being replaced. Before welding began, an employee observed 3.5 barrels of jet fuel on the ground that had leaked from the 8 inch riser.