-

What happened?

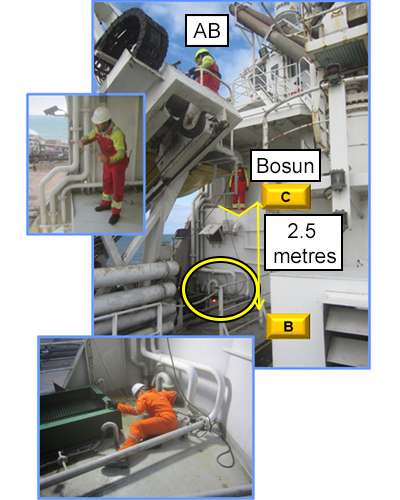

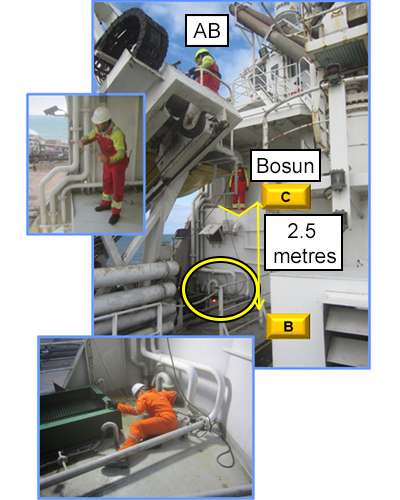

A bosun was changing a wire on a fast rescue craft (FRC) davit.

At the end of the operation, he proceeded to a place where he could monitor the stowage of the FRC (see image).

The area of deck near to where the FRC bow was stowed was uneven and sloped to allow for FRC stowage.

The bosun slipped and fell to the deck 2.5 metres (8 feet) to the deck below, breaking his ankle.

He missed landing on several obstructions, which had the potential to cause life-changing injuries had he landed on them.

-

Why did it happen?

There was no barrier or guard to prevent a fall when the FRC was not in the stowed position.

- The design of the area when the FRC was stowed meant the area could not be fenced off. The stowed FRC fully closed off the area, mitigating the risk of falling from height.

The area where the bosun was standing was not marked as hazardous.

The bosun’s safety shoes were exposed to oily residues. That potentially contributed to slipping.

The job safety analysis (JSA) and permit to work (PTW) did not identify the falling hazard.

The incident was not an isolated situation, it would be recurring for each launch/retrieval of FRC.

-

What did they learn?

Review and update (if required) the job safety analysis (JSA) for FRC launch/retrieval.

Investigate whether ‘working at height’ precautions should be applied to be more tasks. Consider whether fall arrestor gear should be used for the task, and increase signage requiring fall protection equipment where needed.

Develop a broader understanding of what ‘working at height’ is or could be.

Implement a dedicated check on all vessels for ‘less visible’ hazards. Use different people to carry out the hazard hunts – enabling a different perspective.

Ensure all workers are fully aware of the risks and mitigating measures for their tasks.

Standardised and frequently repeated tasks are not risk free!

- Reinforce that workers should take care when carrying out standardised tasks and take as much care when cleaning up after the work is completed.

-

Ask yourself or your crew

What are the hazards included in your risk assessment for this job? What should you do if you have identified other hazards?

Have you conducted a hazard hunt for this job?

- If you have, what did you spot?

- If not, why haven’t you?

What are our procedures for working at height?

What mitigating measures do we have in place if something goes wrong?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A bosun was changing a wire on a fast rescue craft (FRC) davit.

At the end of the operation, he proceeded to a place where he could monitor the stowage of the FRC (see image).

The area of deck near to where the FRC bow was stowed was uneven and sloped to allow for FRC stowage.

The bosun slipped and fell to the deck 2.5 metres (8 feet) to the deck below, breaking his ankle.

He missed landing on several obstructions, which had the potential to cause life-changing injuries had he landed on them.

Why did it happen?

There was no barrier or guard to prevent a fall when the FRC was not in the stowed position.

- The design of the area when the FRC was stowed meant the area could not be fenced off. The stowed FRC fully closed off the area, mitigating the risk of falling from height.

The area where the bosun was standing was not marked as hazardous.

The bosun’s safety shoes were exposed to oily residues. That potentially contributed to slipping.

The job safety analysis (JSA) and permit to work (PTW) did not identify the falling hazard.

The incident was not an isolated situation, it would be recurring for each launch/retrieval of FRC.

What did they learn?

Review and update (if required) the job safety analysis (JSA) for FRC launch/retrieval.

Investigate whether ‘working at height’ precautions should be applied to be more tasks. Consider whether fall arrestor gear should be used for the task, and increase signage requiring fall protection equipment where needed.

Develop a broader understanding of what ‘working at height’ is or could be.

Implement a dedicated check on all vessels for ‘less visible’ hazards. Use different people to carry out the hazard hunts – enabling a different perspective.

Ensure all workers are fully aware of the risks and mitigating measures for their tasks.

Standardised and frequently repeated tasks are not risk free!

- Reinforce that workers should take care when carrying out standardised tasks and take as much care when cleaning up after the work is completed.

Ask yourself or your crew

What are the hazards included in your risk assessment for this job? What should you do if you have identified other hazards?

Have you conducted a hazard hunt for this job?

- If you have, what did you spot?

- If not, why haven’t you?

What are our procedures for working at height?

What mitigating measures do we have in place if something goes wrong?

A worker was changing a wire on an FRC davit. After completing their task, they moved to the FRC bow where the deck was sloped, and the worker slipped to the deck below.