-

What happened?

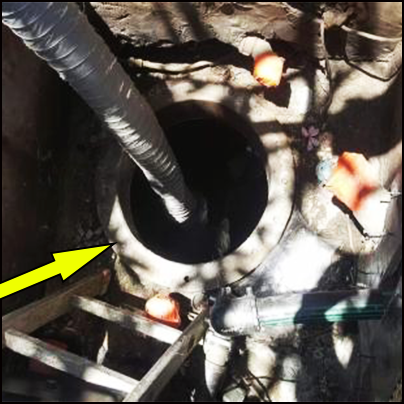

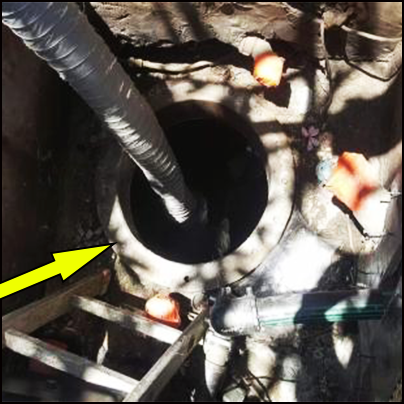

As part of a cleaning and degassing operation, a tank had been rinsed and cleaned. Using a truck, water was pumped from outside and air extracted by suction for 30 minutes.

An operator descended in the tank to finish cleaning it with a high-pressure lance.

He was wearing personal protective equipment (chemical suit, a cartridge half-mask, a 4-gas detector and a harness connected to a tripod installed over the manhole).

His eyes started tingling and he smelled a strong smell of gasoline. His gas detector immediately alarmed.

He held his breath while the ladder was repositioned, and then climbed out.

His colleagues quickly removed his mask so he could breathe and took him to be examined by a doctor. He was suffering from shock.

-

Why did it happen?

No gas test was conducted before entering the tank.

No permit for confined space was obtained.

No air breathing equipment was provided.

The mask was incorrectly positioned on the operator's face (possibly shifted during descent).

The ladder was removed from the manhole after he entered, delaying evacuation.

No communication between the operators. Everyone thought that the gas test had been done. Operators had too much to do and too little time to do it.

The procedure was inadequate and incomplete.

Work was not supervised.

-

What did they learn?

Revise the tank cleaning and degassing procedure and job safety analysis.

Incorporate use of gas detectors into the procedures.

Make more gas detectors available.

Train people to use gas detectors and take precautions to avoid malfunctions.

Practice emergency exercises with contractors, e.g. evacuation and emergency response.

Do not become overconfident – even if operators and contractors are considered to be ‘experienced’.

-

Ask yourself or your crew

How can something like this happen here?

Have we (or should we) conduct a gas test?

How do we use gas detecting equipment? Where do we test?

What controls do we have in place for confined space entry? How do we know these controls will keep us safe?

How can we improve the procedure for today’s task?

What else can we learn from this incident?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

As part of a cleaning and degassing operation, a tank had been rinsed and cleaned. Using a truck, water was pumped from outside and air extracted by suction for 30 minutes.

An operator descended in the tank to finish cleaning it with a high-pressure lance.

He was wearing personal protective equipment (chemical suit, a cartridge half-mask, a 4-gas detector and a harness connected to a tripod installed over the manhole).

His eyes started tingling and he smelled a strong smell of gasoline. His gas detector immediately alarmed.

He held his breath while the ladder was repositioned, and then climbed out.

His colleagues quickly removed his mask so he could breathe and took him to be examined by a doctor. He was suffering from shock.

Why did it happen?

No gas test was conducted before entering the tank.

No permit for confined space was obtained.

No air breathing equipment was provided.

The mask was incorrectly positioned on the operator's face (possibly shifted during descent).

The ladder was removed from the manhole after he entered, delaying evacuation.

No communication between the operators. Everyone thought that the gas test had been done. Operators had too much to do and too little time to do it.

The procedure was inadequate and incomplete.

Work was not supervised.

What did they learn?

Revise the tank cleaning and degassing procedure and job safety analysis.

Incorporate use of gas detectors into the procedures.

Make more gas detectors available.

Train people to use gas detectors and take precautions to avoid malfunctions.

Practice emergency exercises with contractors, e.g. evacuation and emergency response.

Do not become overconfident – even if operators and contractors are considered to be ‘experienced’.

Ask yourself or your crew

How can something like this happen here?

Have we (or should we) conduct a gas test?

How do we use gas detecting equipment? Where do we test?

What controls do we have in place for confined space entry? How do we know these controls will keep us safe?

How can we improve the procedure for today’s task?

What else can we learn from this incident?

An operator entered a tank to clean it. The ladder was removed. He smelled gasoline and his eyes stung. He held his breath while the ladder was positioned and managed to exit the tank.