-

What happened?

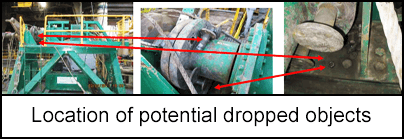

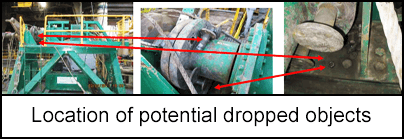

A vessel was loaded a spooling unit and other cargo onto a platform.

After lifting operations were completed, the platform reported 19 loose and unsecured objects on top of the spooling unit:

- Spooler locking pins weighing 7 kg (15.5 lbs) each.

- Securing nuts and bolts.

- Unsecured spooler in cradle.

- Unsecured gratings.

- Unattached grating securing chain.

-

Why did it happen?

Work instructions, procedures, and company safety requirements were not followed.

There had been three chances to check for potential dropped objects, but all three were missed:

- The vendor did not properly check the spooler unit before shipment

- Crew on the quayside did not properly check the unit before loading onto the vessel.

- The vessel’s deck crew did not visually check the upper working platform of the spooling unit for any loose items before lifting the load to the platform, despite a direct requirement of vessel owner’s safety management system (SMS).

-

What did they learn?

Large and complex objects should be thoroughly inspected for potential dropped objects at every stage of the transportation process.

Do not under-estimate the hazards of loose objects falling from loads during loading operations.

Workers should be alert at all times to the danger of potential dropped objects.

Workers should never position themselves under a load.

-

Ask yourself or your crew

What is the worst that could have happened?

What measures do we have in place to prevent something similar happening on our site?

What is your procedure for checking for potential dropped objects? At what stage is this carried out?

What damage could dropped objects cause on your site?

How do you stay alert for potential dropped objects and other dangers around you?

Is there a punitive measure for non-compliance? If not, what should that be?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A vessel was loaded a spooling unit and other cargo onto a platform.

After lifting operations were completed, the platform reported 19 loose and unsecured objects on top of the spooling unit:

- Spooler locking pins weighing 7 kg (15.5 lbs) each.

- Securing nuts and bolts.

- Unsecured spooler in cradle.

- Unsecured gratings.

- Unattached grating securing chain.

Why did it happen?

Work instructions, procedures, and company safety requirements were not followed.

There had been three chances to check for potential dropped objects, but all three were missed:

- The vendor did not properly check the spooler unit before shipment

- Crew on the quayside did not properly check the unit before loading onto the vessel.

- The vessel’s deck crew did not visually check the upper working platform of the spooling unit for any loose items before lifting the load to the platform, despite a direct requirement of vessel owner’s safety management system (SMS).

What did they learn?

Large and complex objects should be thoroughly inspected for potential dropped objects at every stage of the transportation process.

Do not under-estimate the hazards of loose objects falling from loads during loading operations.

Workers should be alert at all times to the danger of potential dropped objects.

Workers should never position themselves under a load.

Ask yourself or your crew

What is the worst that could have happened?

What measures do we have in place to prevent something similar happening on our site?

What is your procedure for checking for potential dropped objects? At what stage is this carried out?

What damage could dropped objects cause on your site?

How do you stay alert for potential dropped objects and other dangers around you?

Is there a punitive measure for non-compliance? If not, what should that be?

A vessel was loaded a spooling unit and other cargo onto a platform. After lifting operations were completed, the platform identified 19 loose objects on top of the spooling unit.