-

What happened?

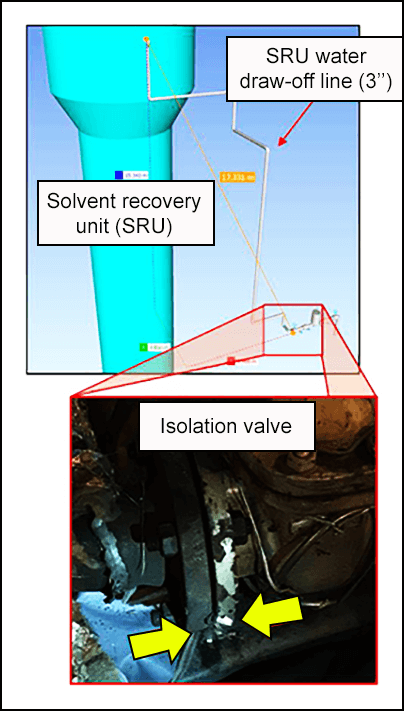

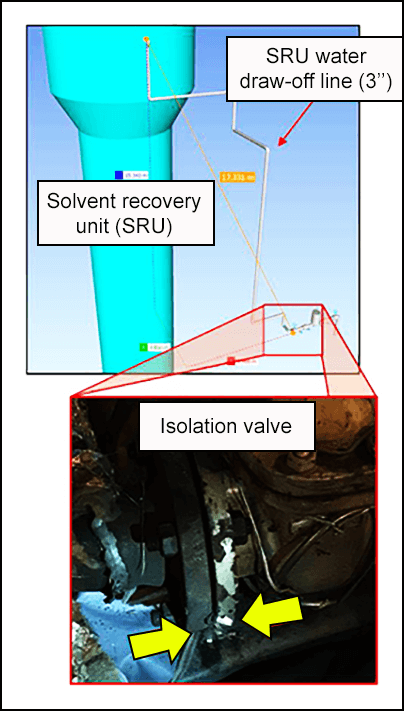

The electric heat tracing (EHT) on a water draw-off line was de-energised on a solvent recovery unit (SRU) column in preparation for other site work.

The work was delayed for six months.

When the work was completed, the EHT was re-energised on the water draw-off line.

As the water draw-off line thawed, a leak occurred from the pipe.

-

Why did it happen?

There was a failed gasket on the water draw-off line isolation valve.

The EHT circuit was de-energised and taken offline in the summer, but the delay to works took the project into the winter, meaning the water draw-off line could freeze.

The EHT was reinstated while the water draw-off line and valve were frozen – the reinstatement process did not take into consideration that the pipe might be frozen/damaged.

EHT monitoring focussed only on circuits that were ‘active’ and not those that were offline.

The long-term isolation review did not take into account all of the possible impacts.

The work pack used to reinstate the circuit focused on personnel safety-related hazards, not process safety hazards.

-

What did they learn?

Confirm that operations are aware of all safeguards that are not in service (e.g. any disabled circuits).

Long term isolation (LTI) reviews should consider any conditions that may have changed since an isolation was put in place. Review EHT on LTI before the cold season.

Reinstatement procedures should consider process safety hazards (e.g. procedures for re-energising EHT circuits considers cold weather hazard).

-

Ask yourself or your crew

What could have happened if the leak would not have been discovered on time?

What risk assessments should you carry out on a project that has been significantly delayed?

Do any of your processes change depending on the season/weather?

What monitoring is carried out on disabled/inactive areas of your workplace, and how is this recorded?

What measures do we have in place to prevent this from happening here? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

The electric heat tracing (EHT) on a water draw-off line was de-energised on a solvent recovery unit (SRU) column in preparation for other site work.

The work was delayed for six months.

When the work was completed, the EHT was re-energised on the water draw-off line.

As the water draw-off line thawed, a leak occurred from the pipe.

Why did it happen?

There was a failed gasket on the water draw-off line isolation valve.

The EHT circuit was de-energised and taken offline in the summer, but the delay to works took the project into the winter, meaning the water draw-off line could freeze.

The EHT was reinstated while the water draw-off line and valve were frozen – the reinstatement process did not take into consideration that the pipe might be frozen/damaged.

EHT monitoring focussed only on circuits that were ‘active’ and not those that were offline.

The long-term isolation review did not take into account all of the possible impacts.

The work pack used to reinstate the circuit focused on personnel safety-related hazards, not process safety hazards.

What did they learn?

Confirm that operations are aware of all safeguards that are not in service (e.g. any disabled circuits).

Long term isolation (LTI) reviews should consider any conditions that may have changed since an isolation was put in place. Review EHT on LTI before the cold season.

Reinstatement procedures should consider process safety hazards (e.g. procedures for re-energising EHT circuits considers cold weather hazard).

Ask yourself or your crew

What could have happened if the leak would not have been discovered on time?

What risk assessments should you carry out on a project that has been significantly delayed?

Do any of your processes change depending on the season/weather?

What monitoring is carried out on disabled/inactive areas of your workplace, and how is this recorded?

What measures do we have in place to prevent this from happening here? How can we improve?

The electric heat tracing (EHT) on a water draw-off line was de-energised on a solvent recovery unit (SRU) column. When the work was completed and the EHT re-energised, a leak was discovered in the water draw-off line.