-

What happened?

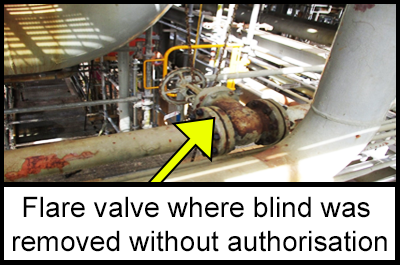

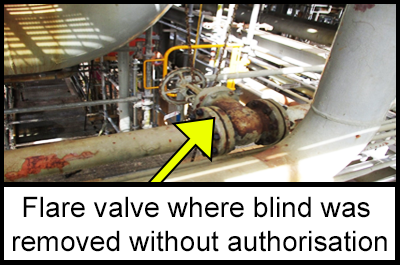

A contractor removed the blind located at the flare header battery limit in the reformer.

While removing the blind, the employee’s hydrogen sulphide (H2S) monitor alarmed at 18 parts per million (ppm).

The employee left the scaffold and reported the incident to his safety adviser.

-

Why did it happen?

The isolation blinds installed did not have locks.

There was no associated blind sheet for the hot work portion of the job.

The contractor did NOT:

- communicate with his supervisor.

- verify whether pulling blinds was part of the work permit.The employee worked outside the permit requirements.

The employee had disengaged a positive isolation from a live system, without personal protection equipment.

-

What did they learn?

Place locks on isolation blinds.

When hydrotesting, tag and review with operations all vents/drains or blind points that are to be manipulated during hydrotesting.

Communicate with your supervisor/team.

Work within the work permits limits.

Wear appropriate PPE, where required. For H2S that means a full face air-supplied respirator, with an emergency egress bottle.

-

Ask yourself or your crew

What other actions could have been taken?

Why do you think this worker did what he did?

How could something similar happen to us?

What barriers can we put in place to prevent us working on the wrong equipment or plant?

How can we improve communication so that everyone knows what they should be doing?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A contractor removed the blind located at the flare header battery limit in the reformer.

While removing the blind, the employee’s hydrogen sulphide (H2S) monitor alarmed at 18 parts per million (ppm).

The employee left the scaffold and reported the incident to his safety adviser.

Why did it happen?

The isolation blinds installed did not have locks.

There was no associated blind sheet for the hot work portion of the job.

The contractor did NOT:

- communicate with his supervisor.

- verify whether pulling blinds was part of the work permit.

The employee worked outside the permit requirements.

The employee had disengaged a positive isolation from a live system, without personal protection equipment.

What did they learn?

Place locks on isolation blinds.

When hydrotesting, tag and review with operations all vents/drains or blind points that are to be manipulated during hydrotesting.

Communicate with your supervisor/team.

Work within the work permits limits.

Wear appropriate PPE, where required. For H2S that means a full face air-supplied respirator, with an emergency egress bottle.

Ask yourself or your crew

What other actions could have been taken?

Why do you think this worker did what he did?

How could something similar happen to us?

What barriers can we put in place to prevent us working on the wrong equipment or plant?

How can we improve communication so that everyone knows what they should be doing?

A temporary stairway between a rig and a flotel was being removed. The load got stuck in a gap. As the rigging supervisor tried to unblock it, the beam clamp came off the end of the monorail, striking his head and shattering his hard hat.