-

What happened?

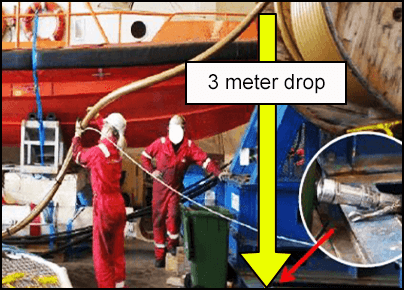

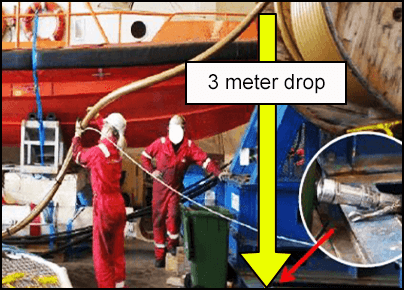

A 1.5 inch hydraulic jumper was being tran-spooled from a wooden reel to a subsea carousel.

During spooling of the first two layers, the second end termination head of the hydraulic jumper pipe (weighing 11 kg / 24 lb) released from the reel and fell 3 m / 9 ft to the floor.

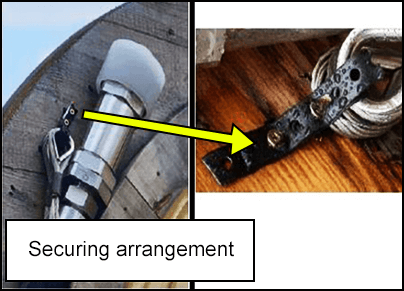

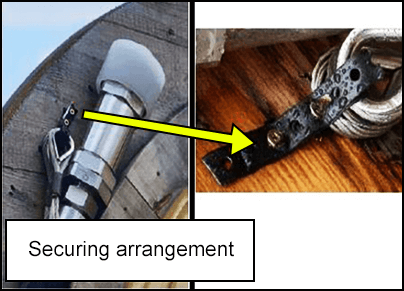

It had been secured using a rubber covered metal band that was fastened to the wooden reel with 2 wood screws.

Five people were working nearby and were in the line of fire. The end termination head missed them and there were no injuries.

-

Why did it happen?

- The distance between the reel and the carousel was too short to allow for the people operating the reel to attach the wire to the jumper and keep a safe distance from the reel when rotating.

- The securing arrangement for the heads, in this case wooden screws, was inadequate. Additionally, a second barrier was not considered necessary.

- This specific risk was highlighted in the task plan. However, the task plan was not properly followed on site before conducting the operation.

- The hazards of potential dropped objects were not properly addressed as part of the pre-job toolbox talk and task risk assessment.

- Some personnel involved were not trained in this type of work.

-

What did they learn?

Termination heads on reels should be highlighted as potential dropped objects in the task risk assessment.

A second barrier should be added before spooling if proper engineered solutions are not in place.

Working closely to a rotating reel should be considered a high risk which should be properly mitigated.

All personnel should be trained for the task they are performing. If there are uncertainties regarding their competence, a competence assessment should be conducted beforehand.

-

Ask yourself or your crew

How can something like this happen here?

How are termination heads secured on our site?

What controls do we have in place to prevent a similar incident? Are we following the plan?

What other hazards are associated with this task, and what can we do to mitigate the risk?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

A 1.5 inch hydraulic jumper was being tran-spooled from a wooden reel to a subsea carousel.

During spooling of the first two layers, the second end termination head of the hydraulic jumper pipe (weighing 11 kg / 24 lb) released from the reel and fell 3 m / 9 ft to the floor.

It had been secured using a rubber covered metal band that was fastened to the wooden reel with 2 wood screws.

Five people were working nearby and were in the line of fire. The end termination head missed them and there were no injuries.

Why did it happen?

- The distance between the reel and the carousel was too short to allow for the people operating the reel to attach the wire to the jumper and keep a safe distance from the reel when rotating.

- The securing arrangement for the heads, in this case wooden screws, was inadequate. Additionally, a second barrier was not considered necessary.

- This specific risk was highlighted in the task plan. However, the task plan was not properly followed on site before conducting the operation.

- The hazards of potential dropped objects were not properly addressed as part of the pre-job toolbox talk and task risk assessment.

- Some personnel involved were not trained in this type of work.

What did they learn?

Termination heads on reels should be highlighted as potential dropped objects in the task risk assessment.

A second barrier should be added before spooling if proper engineered solutions are not in place.

Working closely to a rotating reel should be considered a high risk which should be properly mitigated.

All personnel should be trained for the task they are performing. If there are uncertainties regarding their competence, a competence assessment should be conducted beforehand.

Ask yourself or your crew

How can something like this happen here?

How are termination heads secured on our site?

What controls do we have in place to prevent a similar incident? Are we following the plan?

What other hazards are associated with this task, and what can we do to mitigate the risk?

During trans-spooling of 1½” hydraulic jumper from a wooden reel to a subsea carousel, the end termination head, weighing 11kg, fell 3 m. Five people were working nearby and were in the line of fire, no one was injured.