-

What happened?

During a planned lift from a crew transfer vessel (CTV) to the wind turbine generator’s (WTG) access platform, a load detached and fell from a height of 5 meters (16 feet).

The 100 kg (220 lb) load landed on the bow of the vessel, causing minor damage to the deck.

No personnel were hurt due to an exclusion zone being put in place before the task.

-

Why did it happen?

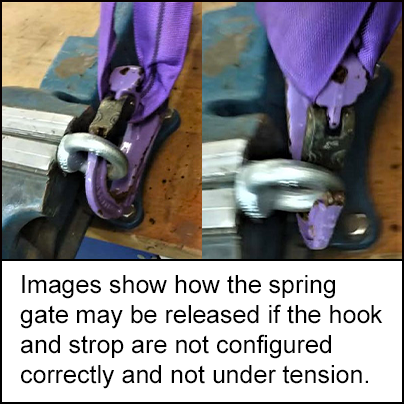

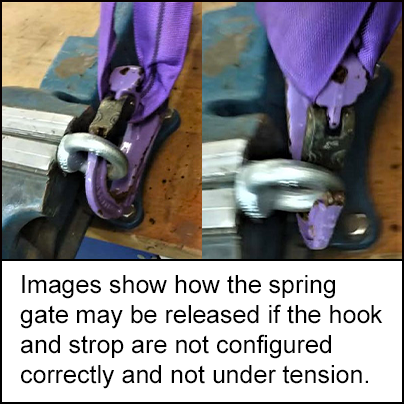

The load was either rigged incorrectly, or the lifting accessory was not appropriate.

As the load was being slewed away from the vessel, the momentum allowed the lifting eye on the load to pass through the gate of the sling hook.

No personnel were injured as a result of good practice. By establishing an exclusion zone before the work started, the risk was minimised.

-

What did they learn?

Only trained personnel should plan and implement any lifting operation (including rigging).

Ensure that lifting equipment and accessories are of the approved type, suitable for the lift, correctly configured and checked prior to the lift.

Ensure the hook is not overcrowded.

If it is safe to do so, check equipment configuration and tension by lifting the load for a short distance only, prior to the full lift.

Following the risk assessment, define an exclusion zone as a safety measure.

-

Ask yourself or your crew

What other actions could have been taken?

How is the exclusion zone established, physically marked on-site and where is it documented?

How do you know where is safe to stand while the lifting operation is taking place?

When is it safe to enter an exclusion zone?

What controls do we have in place to prevent this from happening on our site? How can we improve?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

During a planned lift from a crew transfer vessel (CTV) to the wind turbine generator’s (WTG) access platform, a load detached and fell from a height of 5 meters (16 feet).

The 100 kg (220 lb) load landed on the bow of the vessel, causing minor damage to the deck.

No personnel were hurt due to an exclusion zone being put in place before the task.

Why did it happen?

The load was either rigged incorrectly, or the lifting accessory was not appropriate.

As the load was being slewed away from the vessel, the momentum allowed the lifting eye on the load to pass through the gate of the sling hook.

No personnel were injured as a result of good practice. By establishing an exclusion zone before the work started, the risk was minimised.

What did they learn?

Only trained personnel should plan and implement any lifting operation (including rigging).

Ensure that lifting equipment and accessories are of the approved type, suitable for the lift, correctly configured and checked prior to the lift.

Ensure the hook is not overcrowded.

If it is safe to do so, check equipment configuration and tension by lifting the load for a short distance only, prior to the full lift.

Following the risk assessment, define an exclusion zone as a safety measure.

Ask yourself or your crew

What other actions could have been taken?

How is the exclusion zone established, physically marked on-site and where is it documented?

How do you know where is safe to stand while the lifting operation is taking place?

When is it safe to enter an exclusion zone?

What controls do we have in place to prevent this from happening on our site? How can we improve?

During a planned lift from a crew transfer vessel (CTV) to the wind turbine generator’s (WTG) access platform, a heavy load detached and fell. The vessel’s deck was damaged, but luckily no personnel was hurt as safe work practices were implemented before the task commenced.