-

What happened?

- Tests were being carried out on a new bottom loading dock.

- Empty lines were filled gradually to check different types of equipment.

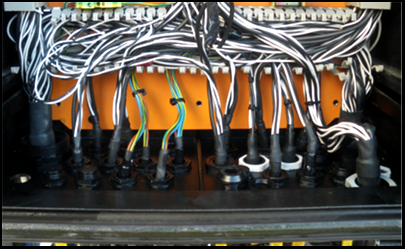

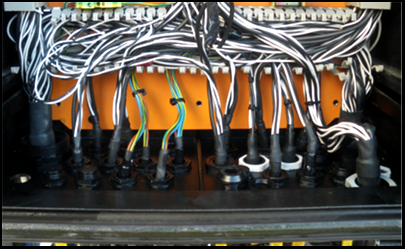

- 15 minutes later, the contractor noticed that diesel oil escaped from an unobstructed cable glanding at the bottom of the switchboard.

- When opening the switchboard, droplets of product flowed from the inside of the cable, forming a thin film in the cable entry area.

- Tests were immediately stopped. Each hydraulic circuit was closed and then depressurised.

- All power supplies were switched off.

- Calibration and commissioning were postponed for 1 week.

- If vapours and a flammable atmosphere would have been created as a result of the leak, a fire/explosion in the electrical cabinet could have occurred.

-

Why did it happen?

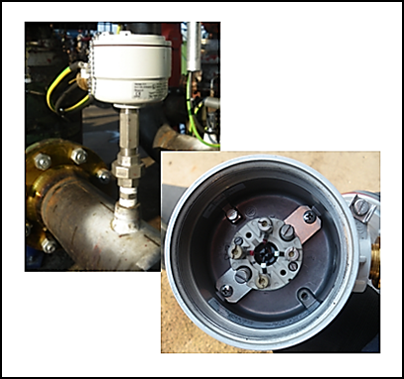

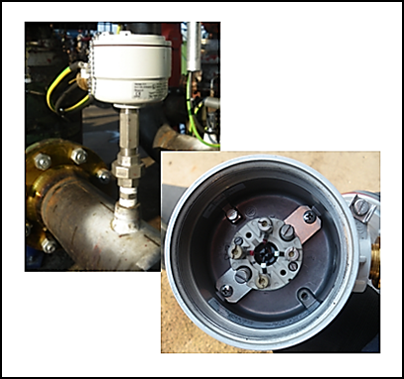

The probe was installed incorrectly. The technician that installed the temperature probe was not aware that it has to be placed in a glove finger, rather than directly in the product.

Due to pressure on the line, gas oil leaked into the head of the probe, where the connection wire terminal of the communication cable is located.

When the pressure inside the housing increased, the product infiltrated inside the cable, between the different wires and the sheath.

The installation error wasn’t noticed by the technicians/experts that checked the probe.

No one noticed the error because it is hard to see how the probe is installed.

-

What did they learn?

Use the manufacturer's instructions to install any new equipment.

In the case of lack of instructions, request installation by a manufacturer/national supplier approved technician.

Should this incident occur:

- clean the switchboard

- disconnect the product-contaminated wire from the temperature probe and replace with a new wire

- dismantle, clean and check the probe

- if necessary, postpone tests until the equipment is correctly installed

-

Ask yourself or your crew

What are the 3 critical safeguards/barriers we have in place here at our site to prevent this type of an event?

Why do you think the technician was unaware of the correct way of installing the probe?

What could have happened if the technician did not notice the escaped oil and carried on testing the equipment?

How do we KNOW that equipment has been correctly installed?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

- Tests were being carried out on a new bottom loading dock.

- Empty lines were filled gradually to check different types of equipment.

- 15 minutes later, the contractor noticed that diesel oil escaped from an unobstructed cable glanding at the bottom of the switchboard.

- When opening the switchboard, droplets of product flowed from the inside of the cable, forming a thin film in the cable entry area.

- Tests were immediately stopped. Each hydraulic circuit was closed and then depressurised.

- All power supplies were switched off.

- Calibration and commissioning were postponed for 1 week.

- If vapours and a flammable atmosphere would have been created as a result of the leak, a fire/explosion in the electrical cabinet could have occurred.

Why did it happen?

The probe was installed incorrectly. The technician that installed the temperature probe was not aware that it has to be placed in a glove finger, rather than directly in the product.

Due to pressure on the line, gas oil leaked into the head of the probe, where the connection wire terminal of the communication cable is located.

When the pressure inside the housing increased, the product infiltrated inside the cable, between the different wires and the sheath.

The installation error wasn’t noticed by the technicians/experts that checked the probe.

No one noticed the error because it is hard to see how the probe is installed.

What did they learn?

Use the manufacturer's instructions to install any new equipment.

In the case of lack of instructions, request installation by a manufacturer/national supplier approved technician.

Should this incident occur:

- clean the switchboard

- disconnect the product-contaminated wire from the temperature probe and replace with a new wire

- dismantle, clean and check the probe

- if necessary, postpone tests until the equipment is correctly installed

Ask yourself or your crew

What are the 3 critical safeguards/barriers we have in place here at our site to prevent this type of an event?

Why do you think the technician was unaware of the correct way of installing the probe?

What could have happened if the technician did not notice the escaped oil and carried on testing the equipment?

How do we KNOW that equipment has been correctly installed?

Tests on a new bottom loading dock were stopped when a technician noticed oil escaping from an unobstructed cable in the switchboard.