-

What happened?

Contractor team arrived early at an office location to paint the inside of a water tank.

The tank had been washed and drained the previous day, ready to be painted.

The operating company arrived and formally opened a short permit to work.

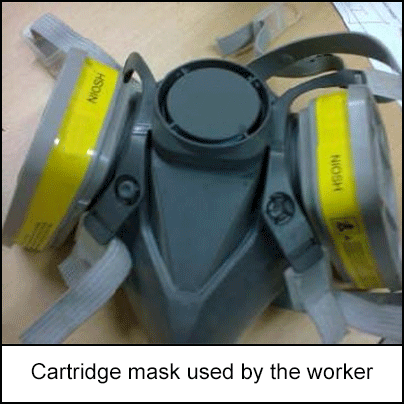

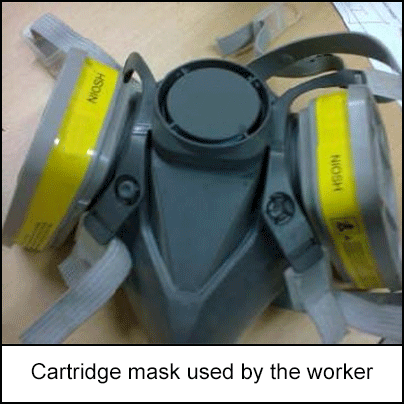

The painter went inside the tank and started painting. After 15 minutes, he went outside to take a short break. He returned into the tank to resume painting, holding his cartridge filter mask.

The supervisor, standing on top of the tank, heard the painter shout. He saw the painter had fallen and lost consciousness.

As no provision had been made for emergency evacuation, it took 10 minutes to pull the victim out of the tank using a body harness.

The painter regained consciousness and was released from a clinic later that day.

-

Why did it happen?

Confined space was not identified on the permit to work. The description of the work was ‘cleaning and painting of a water reservoir’.

Job safety analysis did not identify all hazards and precautions for work in confined space: toxic organic vapours, accumulation of flammable organic vapours inside the tank, etc.

Personal protective equipment (PPE) not used: The worker had not put on his cartridge mask when returning into the water tank.

Wrong PPE: Mask cartridge can only be used for outside painting. Does not protect against lack of oxygen inside the tank.

Inadequate ventilation: no forced ventilation to evacuate paint vapours and inject fresh air. Air ventilator was not provided for the job.

The team ignored or were unaware of basic HSE rules. There was a language barrier between the supervisor and the painter. The supervisor on site had no knowledge of work in confined space.

-

What did they learn?

Ensure everyone involved understands the importance of the work permit process. Do not treat it as mere paperwork!

Ensure the description of the task on the permit is complete and accurate.

Ensure all measures identified on the permit to work are correctly implemented prior to the start of work: adequate supervision, PPE, correct material/equipment, etc.

Any change or deviation, no matter how urgent or small, must lead to risk analysis.

Conduct refresher training on a permit to work. Ensure people understand their responsibilities.

Hold a ‘toolbox talk’ before all tasks to review company rules, life-saving actions and stop work authority.

Prepare simple site instructions for all works covered by a short permit. Formalise what can be covered by a short permit, and what cannot.

-

Ask yourself or your crew

How can something like this happen here?

What is the purpose of a permit to work?

How do we know that all relevant confined space hazards have been assessed in the job risk analysis?

What confined space entry controls do we have in place? What else do we need?

What PPE do we have? How do we know it is the right type?

What is the plan in the event of an emergency?

What else can we learn from this incident?

Add to homescreen

Content name

Select existing category:

Content name

New collection

Edit collection

What happened?

Contractor team arrived early at an office location to paint the inside of a water tank.

The tank had been washed and drained the previous day, ready to be painted.

The operating company arrived and formally opened a short permit to work.

The painter went inside the tank and started painting. After 15 minutes, he went outside to take a short break. He returned into the tank to resume painting, holding his cartridge filter mask.

The supervisor, standing on top of the tank, heard the painter shout. He saw the painter had fallen and lost consciousness.

As no provision had been made for emergency evacuation, it took 10 minutes to pull the victim out of the tank using a body harness.

The painter regained consciousness and was released from a clinic later that day.

Why did it happen?

Confined space was not identified on the permit to work. The description of the work was ‘cleaning and painting of a water reservoir’.

Job safety analysis did not identify all hazards and precautions for work in confined space: toxic organic vapours, accumulation of flammable organic vapours inside the tank, etc.

Personal protective equipment (PPE) not used: The worker had not put on his cartridge mask when returning into the water tank.

Wrong PPE: Mask cartridge can only be used for outside painting. Does not protect against lack of oxygen inside the tank.

Inadequate ventilation: no forced ventilation to evacuate paint vapours and inject fresh air. Air ventilator was not provided for the job.

The team ignored or were unaware of basic HSE rules. There was a language barrier between the supervisor and the painter. The supervisor on site had no knowledge of work in confined space.

What did they learn?

Ensure everyone involved understands the importance of the work permit process. Do not treat it as mere paperwork!

Ensure the description of the task on the permit is complete and accurate.

Ensure all measures identified on the permit to work are correctly implemented prior to the start of work: adequate supervision, PPE, correct material/equipment, etc.

Any change or deviation, no matter how urgent or small, must lead to risk analysis.

Conduct refresher training on a permit to work. Ensure people understand their responsibilities.

Hold a ‘toolbox talk’ before all tasks to review company rules, life-saving actions and stop work authority.

Prepare simple site instructions for all works covered by a short permit. Formalise what can be covered by a short permit, and what cannot.

Ask yourself or your crew

How can something like this happen here?

What is the purpose of a permit to work?

How do we know that all relevant confined space hazards have been assessed in the job risk analysis?

What confined space entry controls do we have in place? What else do we need?

What PPE do we have? How do we know it is the right type?

What is the plan in the event of an emergency?

What else can we learn from this incident?

A painter lost consciousness while painting the internal portion of a water tank. The permit had not identified the job as confined space, and PPE was incorrect and not worn.